- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 05:19

Back to list

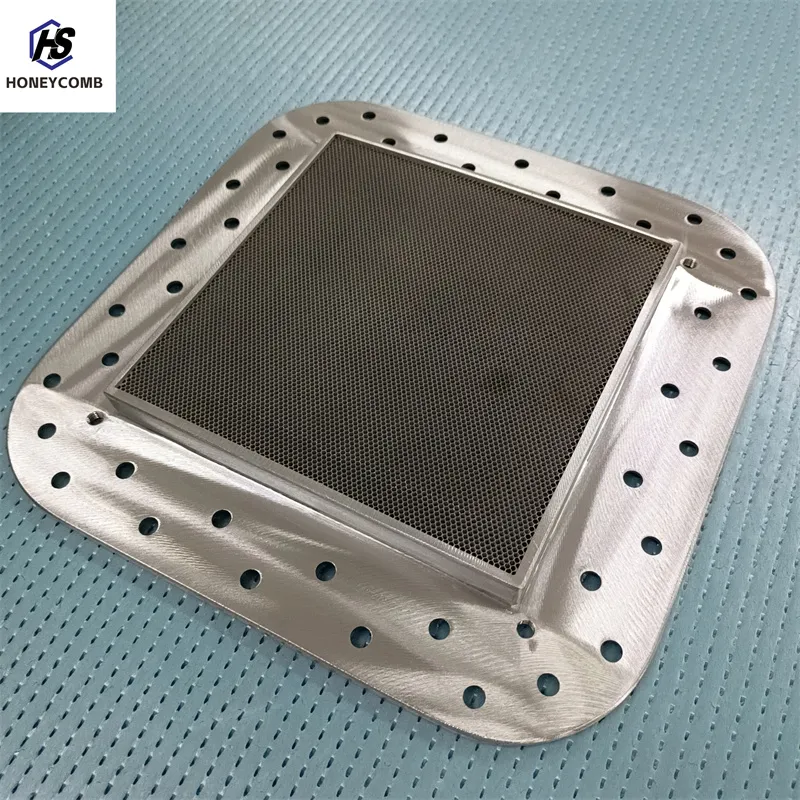

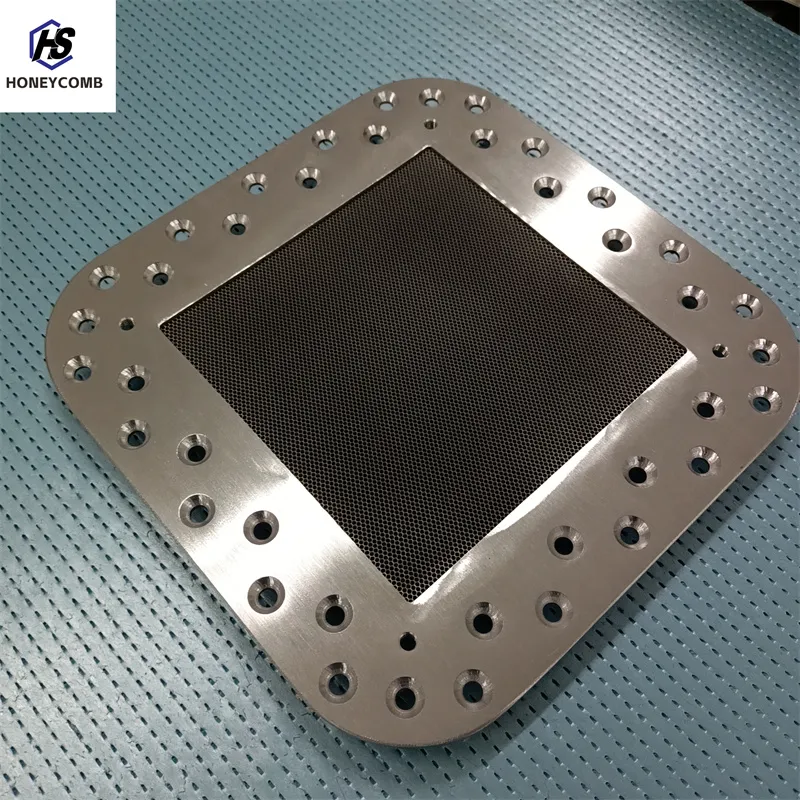

maf honeycomb screen

Steel honeycomb sheets have emerged as a revolutionary material in various industries, providing unmatched benefits due to their unique structure and composition. Constructed using stainless steel, these sheets offer a perfect blend of strength, durability, and versatility, making them an essential choice for sectors demanding high-performance materials.

For the marine environment, the high corrosion resistance of stainless steel honeycomb sheets is invaluable for constructing ships and submarines. These sheets stand resilient against the constant assault of saltwater, preserving the integrity of the vessel while significantly reducing maintenance costs over the ship's lifetime. The material's innate ability to absorb impacts also adds an extra layer of safety for both crew and cargo. Stainless steel honeycomb sheets are essential in cleanroom environments where hygiene and sterility can never be compromised. These sheets are easy to clean and provide a non-porous barrier against contamination, making them ideal for pharmaceutical and microelectronic applications. The sheets' ability to endure intense cleaning cycles without degrading positions them as a trustworthy material in industries where product integrity is paramount. Choosing the right supplier is critical to maximizing the potential benefits of stainless steel honeycomb sheets. Reputable suppliers provide comprehensive product data, ensuring that their materials meet stringent industry standards. They also offer tailored solutions to meet specific project needs, reinforcing the design vision while incorporating practical value. Trustworthy suppliers back their products with robust warranties and rely on transparent business practices to build enduring client relationships. For decision-makers tasked with sourcing materials that balance quality, cost, and sustainability, stainless steel honeycomb sheets present a compelling solution. Their successful application across multiple industries testifies not only to their functional prowess but also to their ability to inspire future innovations. As technology advances, the potential applications for steel honeycomb structures will undoubtedly expand, unlocking new possibilities and transforming visions of what the future could look like.

For the marine environment, the high corrosion resistance of stainless steel honeycomb sheets is invaluable for constructing ships and submarines. These sheets stand resilient against the constant assault of saltwater, preserving the integrity of the vessel while significantly reducing maintenance costs over the ship's lifetime. The material's innate ability to absorb impacts also adds an extra layer of safety for both crew and cargo. Stainless steel honeycomb sheets are essential in cleanroom environments where hygiene and sterility can never be compromised. These sheets are easy to clean and provide a non-porous barrier against contamination, making them ideal for pharmaceutical and microelectronic applications. The sheets' ability to endure intense cleaning cycles without degrading positions them as a trustworthy material in industries where product integrity is paramount. Choosing the right supplier is critical to maximizing the potential benefits of stainless steel honeycomb sheets. Reputable suppliers provide comprehensive product data, ensuring that their materials meet stringent industry standards. They also offer tailored solutions to meet specific project needs, reinforcing the design vision while incorporating practical value. Trustworthy suppliers back their products with robust warranties and rely on transparent business practices to build enduring client relationships. For decision-makers tasked with sourcing materials that balance quality, cost, and sustainability, stainless steel honeycomb sheets present a compelling solution. Their successful application across multiple industries testifies not only to their functional prowess but also to their ability to inspire future innovations. As technology advances, the potential applications for steel honeycomb structures will undoubtedly expand, unlocking new possibilities and transforming visions of what the future could look like.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025