- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 05, 2025 03:00

Back to list

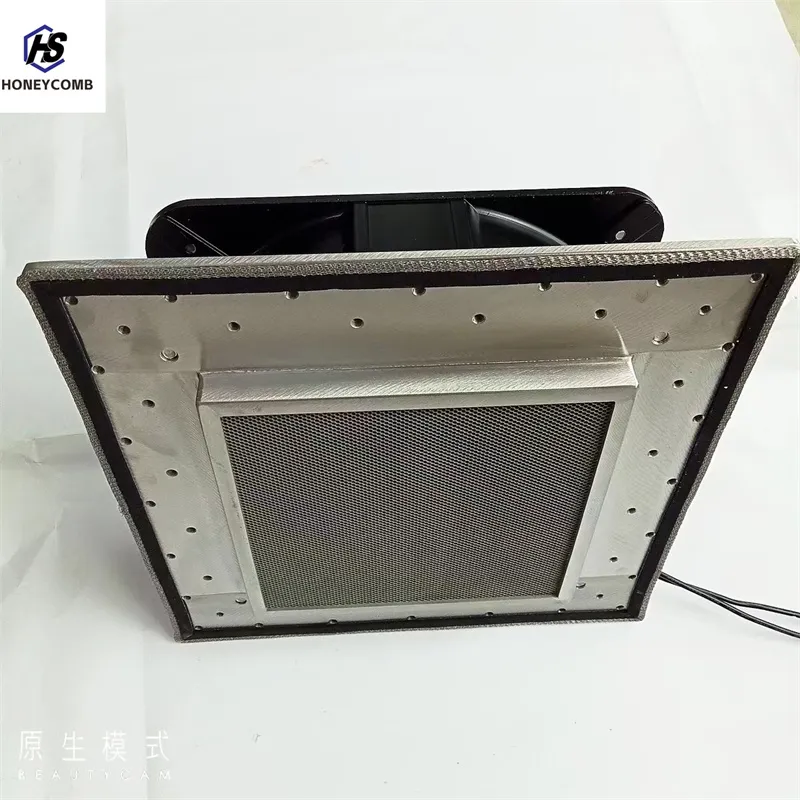

intake air straightener

In the evolving landscape of modern architecture and interior design, honeycomb EMI ventilation openings serve as a perfect synthesis of functionality and style. These superior products not only ensure optimal airflow in various settings but also effectively shield electronic devices from electromagnetic interference (EMI), making them an indispensable component in environments where high-performance EMI control is critical.

Experts within the field, from electronic design specialists to HVAC engineers, emphasize the adaptability and range of customization options associated with these vents. Tailorable to fit specific design constraints, these solutions are available in a variety of sizes and thicknesses, meeting the diverse requirements of different projects. This adaptability ensures that no matter the unique challenges, honeycomb EMI ventilation openings can be integrated seamlessly into any design. Investing in honeycomb EMI ventilation solutions also conveys a commitment to safety and efficiency. Facilities that employ these components often experience improved thermal management, reducing the risk of overheating which is imperative in data centers and industrial electronics settings. The dual function of these vents in providing aerodynamic ventilation while safeguarding against EMI makes them a wise investment for professionals overseeing complex electronic systems. In terms of installation and maintenance, the straightforward process associated with these products aids their appeal. The lightweight yet robust materials used ensure that installation can be executed with minimal exertion, and their construction allows for easy cleaning without the risk of degrading EMI protection. Once installed, these covers continue to deliver peak performance with little to no maintenance, ensuring consistent protection over time. The importance of sourcing from reputable suppliers cannot be overemphasized. Choosing products from a manufacturer with a proven track record of quality assurance not only guarantees performance but also upholds standards of safety and compliance with industrial EMI regulations. This important step lends additional credibility and trustworthiness to the products deployed across any project. Harnessing the full potential of honeycomb EMI ventilation openings, therefore, is not just about choosing a product; it’s about engaging in a partnership with technology that enhances operational integrity, promotes safety, and achieves efficient environmental control. Trusted by industry leaders and backed by expert engineering, these ventilation solutions represent a pinnacle in electromagnetic protection and airflow management technology.

Experts within the field, from electronic design specialists to HVAC engineers, emphasize the adaptability and range of customization options associated with these vents. Tailorable to fit specific design constraints, these solutions are available in a variety of sizes and thicknesses, meeting the diverse requirements of different projects. This adaptability ensures that no matter the unique challenges, honeycomb EMI ventilation openings can be integrated seamlessly into any design. Investing in honeycomb EMI ventilation solutions also conveys a commitment to safety and efficiency. Facilities that employ these components often experience improved thermal management, reducing the risk of overheating which is imperative in data centers and industrial electronics settings. The dual function of these vents in providing aerodynamic ventilation while safeguarding against EMI makes them a wise investment for professionals overseeing complex electronic systems. In terms of installation and maintenance, the straightforward process associated with these products aids their appeal. The lightweight yet robust materials used ensure that installation can be executed with minimal exertion, and their construction allows for easy cleaning without the risk of degrading EMI protection. Once installed, these covers continue to deliver peak performance with little to no maintenance, ensuring consistent protection over time. The importance of sourcing from reputable suppliers cannot be overemphasized. Choosing products from a manufacturer with a proven track record of quality assurance not only guarantees performance but also upholds standards of safety and compliance with industrial EMI regulations. This important step lends additional credibility and trustworthiness to the products deployed across any project. Harnessing the full potential of honeycomb EMI ventilation openings, therefore, is not just about choosing a product; it’s about engaging in a partnership with technology that enhances operational integrity, promotes safety, and achieves efficient environmental control. Trusted by industry leaders and backed by expert engineering, these ventilation solutions represent a pinnacle in electromagnetic protection and airflow management technology.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025