- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 10, 2025 21:41

Back to list

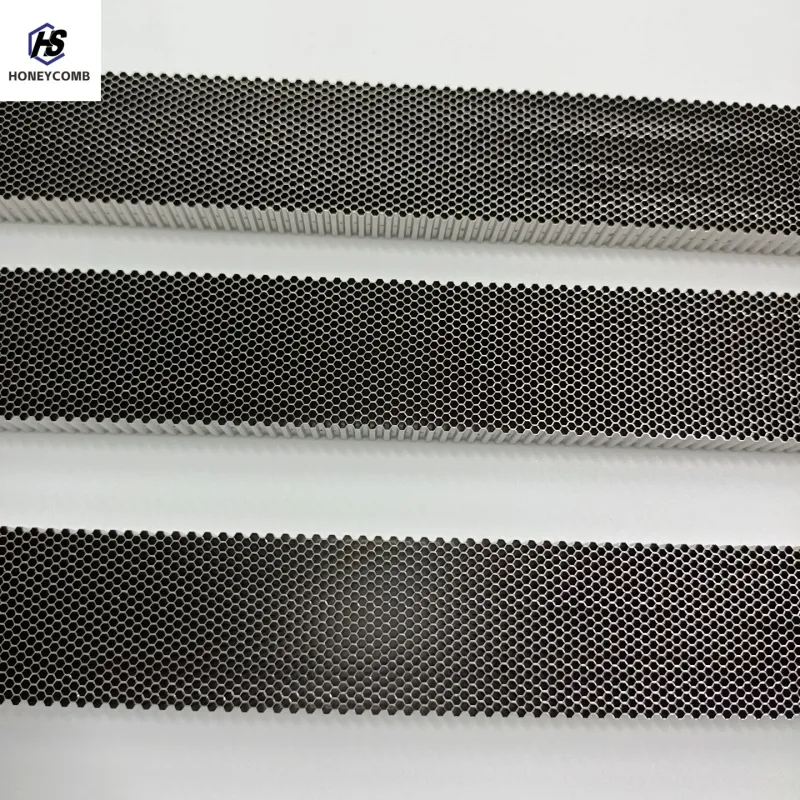

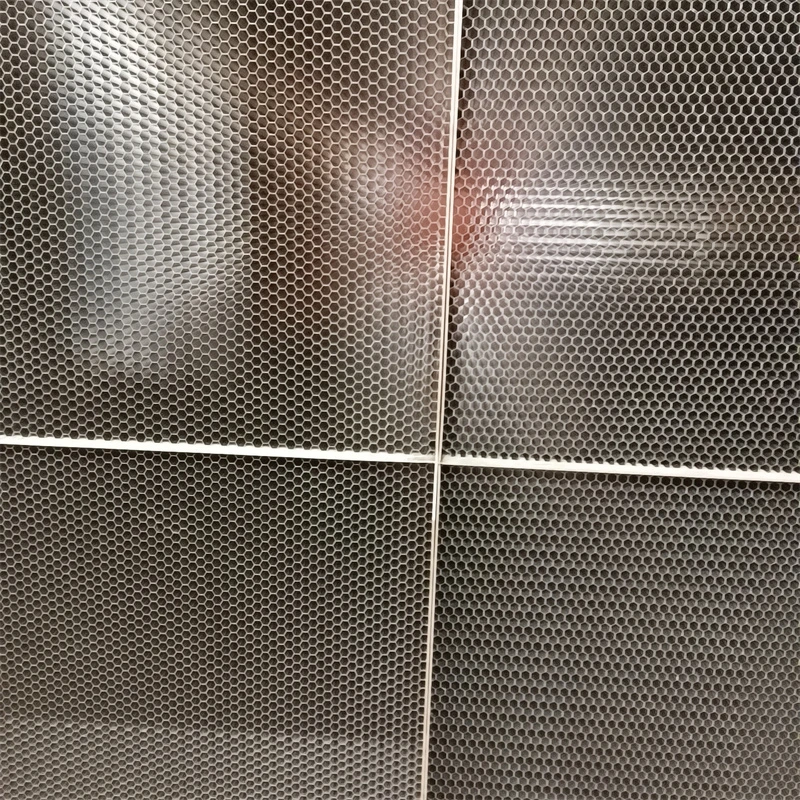

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

Aluminum honeycomb structures have become a pivotal innovation in various industries due to their exceptional mechanical properties and lightweight characteristics. These structures consist of hexagonal aluminum cells, designed to mimic the natural efficiency of a honeycomb, offering significant advantages in applications ranging from aerospace to modern architecture.

In the realm of transportation, aluminum honeycomb is utilized in the production of high-speed trains, automotive components, and marine vessels. The combination of lightweight properties and structural strength facilitates increased speed and improved fuel efficiency. This advancement not only reduces the carbon footprint associated with transportation but also opens up new possibilities for design innovations and passenger comfort. Beyond mechanical applications, aluminum honeycomb structures are also making strides in creative fields such as art installations and contemporary furniture design. Artists and designers are leveraging the material’s distinct texture to craft pieces that are both functional and aesthetically pleasing. The interplay of light and shadow across the hexagonal surfaces produces a dynamic visual effect, adding sophistication to any space. The recyclability of aluminum further underscores the material's sustainability. Aluminum can be recycled indefinitely without loss of quality, making honeycomb structures an environmentally friendly option for eco-conscious industries. Implementing these materials not only supports sustainable practices but also contributes to a circular economy, where resources are reused and recycled for continuous value creation. In conclusion, the multifaceted benefits of aluminum honeycomb structures position them as a revolutionary material in modern innovation. Their lightweight nature combined with unparalleled strength and versatility makes them an invaluable asset across industries, from aerospace engineering to sustainable architecture. As technological advancements continue to refine their production and application, aluminum honeycomb panels are set to play a crucial role in shaping the future of design and engineering. The growing adoption of these structures reflects a broader shift towards materials that are not only performance-oriented but also sustainable and adaptive to the demands of the future.

In the realm of transportation, aluminum honeycomb is utilized in the production of high-speed trains, automotive components, and marine vessels. The combination of lightweight properties and structural strength facilitates increased speed and improved fuel efficiency. This advancement not only reduces the carbon footprint associated with transportation but also opens up new possibilities for design innovations and passenger comfort. Beyond mechanical applications, aluminum honeycomb structures are also making strides in creative fields such as art installations and contemporary furniture design. Artists and designers are leveraging the material’s distinct texture to craft pieces that are both functional and aesthetically pleasing. The interplay of light and shadow across the hexagonal surfaces produces a dynamic visual effect, adding sophistication to any space. The recyclability of aluminum further underscores the material's sustainability. Aluminum can be recycled indefinitely without loss of quality, making honeycomb structures an environmentally friendly option for eco-conscious industries. Implementing these materials not only supports sustainable practices but also contributes to a circular economy, where resources are reused and recycled for continuous value creation. In conclusion, the multifaceted benefits of aluminum honeycomb structures position them as a revolutionary material in modern innovation. Their lightweight nature combined with unparalleled strength and versatility makes them an invaluable asset across industries, from aerospace engineering to sustainable architecture. As technological advancements continue to refine their production and application, aluminum honeycomb panels are set to play a crucial role in shaping the future of design and engineering. The growing adoption of these structures reflects a broader shift towards materials that are not only performance-oriented but also sustainable and adaptive to the demands of the future.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025