- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 15:37

Back to list

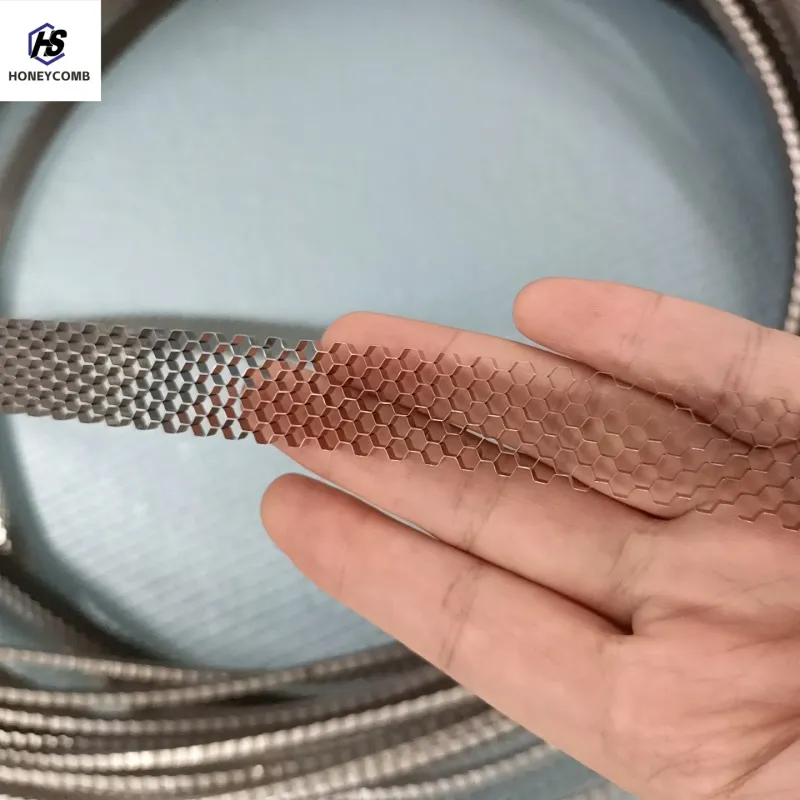

Manufacturer Supply 10mm Stainless Steel 304 Honeycomb for Wind Tunnels Air Flow Testing

In recent years, there has been a burgeoning interest in innovative materials that enhance both the performance and aesthetics of modern architectural and industrial applications. Among these, honeycomb stainless steel, known as acier inoxydable en nid d'abeille in French, stands out due to its unique combination of properties and applications.

The versatility of honeycomb stainless steel extends beyond traditional industries. In the maritime sector, shipbuilders employ this material in constructing bulkheads and decks, taking advantage of its resistance to saline environments. In the automotive industry, manufacturers apply it in creating components that require a balance of strength and weight reduction, such as chassis and body panels. Industry experts commend the adaptability of honeycomb stainless steel, highlighting its integration into cutting-edge design and engineering processes. As innovations in welding and bonding techniques advance, the potential applications of this remarkable material continue to expand, prompting further research and development. Specialists emphasize the importance of partnering with reputed suppliers who possess deep expertise in producing high-quality honeycomb stainless steel. This ensures that products meet industry standards and client expectations while leveraging the material’s full advantages. Establishing trust with suppliers who demonstrate a strong commitment to R&D and quality assurance further enhances the reliability and performance of products using honeycomb stainless steel. In conclusion, honeycomb stainless steel represents the pinnacle of modern material science, seamlessly blending functionality, aesthetics, and sustainability. Its diverse applications across numerous industries underscore the material's adaptability and value. As technology continues to evolve, honeycomb stainless steel is poised to become an integral part of innovative engineering solutions, heralding a future where design and strength are harmoniously united.

The versatility of honeycomb stainless steel extends beyond traditional industries. In the maritime sector, shipbuilders employ this material in constructing bulkheads and decks, taking advantage of its resistance to saline environments. In the automotive industry, manufacturers apply it in creating components that require a balance of strength and weight reduction, such as chassis and body panels. Industry experts commend the adaptability of honeycomb stainless steel, highlighting its integration into cutting-edge design and engineering processes. As innovations in welding and bonding techniques advance, the potential applications of this remarkable material continue to expand, prompting further research and development. Specialists emphasize the importance of partnering with reputed suppliers who possess deep expertise in producing high-quality honeycomb stainless steel. This ensures that products meet industry standards and client expectations while leveraging the material’s full advantages. Establishing trust with suppliers who demonstrate a strong commitment to R&D and quality assurance further enhances the reliability and performance of products using honeycomb stainless steel. In conclusion, honeycomb stainless steel represents the pinnacle of modern material science, seamlessly blending functionality, aesthetics, and sustainability. Its diverse applications across numerous industries underscore the material's adaptability and value. As technology continues to evolve, honeycomb stainless steel is poised to become an integral part of innovative engineering solutions, heralding a future where design and strength are harmoniously united.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025