- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 21:45

Back to list

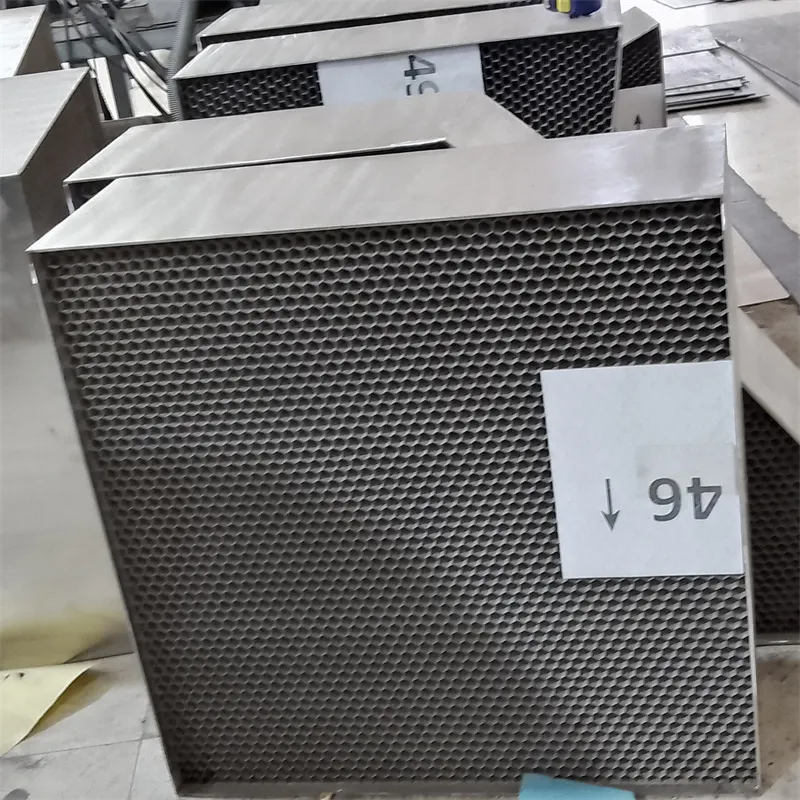

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Air flow straighteners play a pivotal role in ensuring optimal performance and efficiency in various applications, from HVAC systems to automotive engineering. Understanding their function and benefits can significantly enhance system design and energy savings.

Moreover, industries such as aerospace and energy generation also benefit from the application of air flow straighteners. In turbines, whether in jet engines or power plants, maintaining consistent air flow is vital for efficiency and safety. Air flow straighteners ensure that air is evenly distributed across the turbine blades, enhancing fuel efficiency and reducing wear and tear. The design and selection of air flow straighteners require a blend of practical experience and technical knowledge. Engineers must consider factors such as the type of system, the acceptable pressure drop, space constraints, and material compatibility. Custom designs may be necessary for specialized applications, underscoring the expertise needed to integrate these devices successfully. Choosing the right material for an air flow straightener is also crucial. Commonly used materials include aluminum, steel, and certain polymers, each offering different benefits such as corrosion resistance, weight reduction, and ease of manufacturing. This decision greatly influences the overall performance and durability of the straightener in its specific application. To maximize the benefits of air flow straighteners, it is essential to perform regular maintenance checks to ensure they remain free from obstructions and damage. Neglecting maintenance can lead to decreased performance and ultimately affect the overall system's functionality. In conclusion, air flow straighteners are indispensable components in many industries, contributing to enhanced efficiency, performance, and reliability of systems reliant on air flow. Their proper design, application, and maintenance are vital for achieving desired outcomes, showcasing the blend of experience, expertise, and authority needed to leverage their full potential. Investing in quality air flow straighteners can lead to significant cost savings and improved operational efficiency, making them a wise choice for any system that depends on precise air flow management.

Moreover, industries such as aerospace and energy generation also benefit from the application of air flow straighteners. In turbines, whether in jet engines or power plants, maintaining consistent air flow is vital for efficiency and safety. Air flow straighteners ensure that air is evenly distributed across the turbine blades, enhancing fuel efficiency and reducing wear and tear. The design and selection of air flow straighteners require a blend of practical experience and technical knowledge. Engineers must consider factors such as the type of system, the acceptable pressure drop, space constraints, and material compatibility. Custom designs may be necessary for specialized applications, underscoring the expertise needed to integrate these devices successfully. Choosing the right material for an air flow straightener is also crucial. Commonly used materials include aluminum, steel, and certain polymers, each offering different benefits such as corrosion resistance, weight reduction, and ease of manufacturing. This decision greatly influences the overall performance and durability of the straightener in its specific application. To maximize the benefits of air flow straighteners, it is essential to perform regular maintenance checks to ensure they remain free from obstructions and damage. Neglecting maintenance can lead to decreased performance and ultimately affect the overall system's functionality. In conclusion, air flow straighteners are indispensable components in many industries, contributing to enhanced efficiency, performance, and reliability of systems reliant on air flow. Their proper design, application, and maintenance are vital for achieving desired outcomes, showcasing the blend of experience, expertise, and authority needed to leverage their full potential. Investing in quality air flow straighteners can lead to significant cost savings and improved operational efficiency, making them a wise choice for any system that depends on precise air flow management.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025