- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 21:17

Back to list

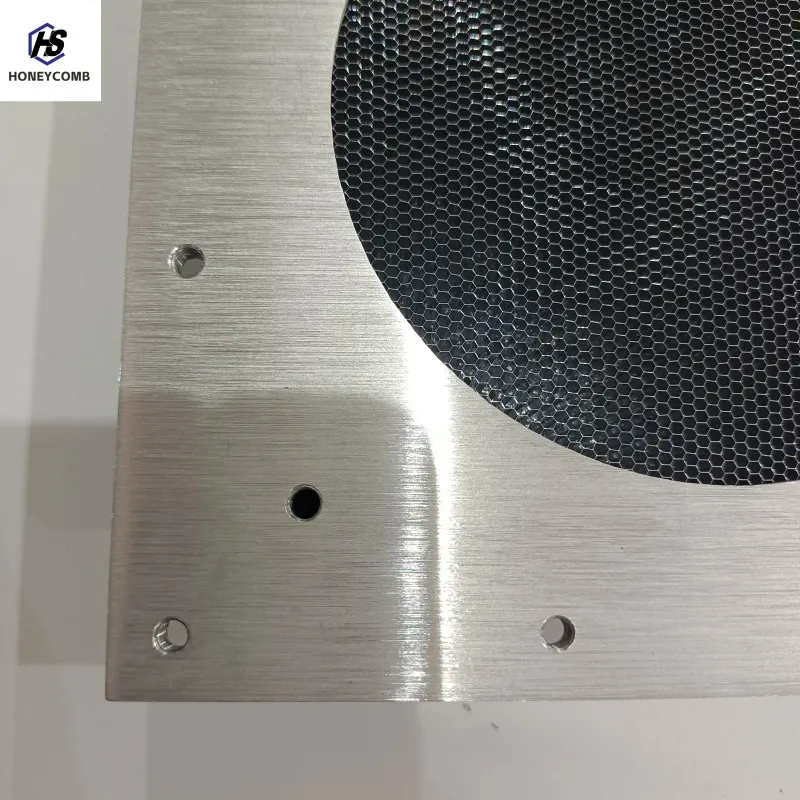

Manufacturer Supply 10mm Stainless Steel 304 Honeycomb for Wind Tunnels Air Flow Testing

The honeycomb air flow straightener is a critical component in various industries, ensuring optimal aerodynamic performance and precision in air flow applications. Enthusiasts and professionals in fields ranging from automotive engineering to sophisticated HVAC systems understand the pivotal role these devices play in enhancing efficiency and reliability.

Analyzing laboratory settings, researchers and scientists prioritize precision above all. Instruments such as wind tunnels and advanced measurement systems, which require consistent air conditions to deliver accurate data, incorporate honeycomb air flow straighteners to achieve this. Experts note that the accuracy of experimental results can be significantly enhanced when the variables introduced by turbulent air flow are minimized, thus highlighting the essential role of straighteners in experimental rigour and credibility. In terms of construction, the materials chosen for honeycomb air flow straighteners can vary depending on the application, with options ranging from lightweight aluminum to robust composites. Each material offers unique advantages durability, resistance to environmental factors, and cost-effectiveness are all considerations that manufacturers balance based on their specific needs. Professionals involved in product development often conduct thorough analysis and testing to determine the most appropriate material for each application, ensuring the longevity and effectiveness of the component. For industry veterans, the use of honeycomb air flow straighteners does not just stop at the improvement of aerodynamics or energy efficiency. There is also an important consideration regarding their contribution to noise reduction. These devices are pivotal in diminishing aerodynamic noise that can arise from turbulent air flows, thereby providing a quieter and more comfortable environment in both industrial and consumer applications. In conclusion, honeycomb air flow straighteners stand as a testament to the intersection of nature-inspired design and advanced engineering. Their ability to transform chaotic air flows into orderly streams touches on the core of engineering principles - efficiency, reliability, and precision. As technology continues to evolve, the role of these components is likely to grow, further embedding them as an essential tool in our pursuit of performance excellence and sustainability across industries.

Analyzing laboratory settings, researchers and scientists prioritize precision above all. Instruments such as wind tunnels and advanced measurement systems, which require consistent air conditions to deliver accurate data, incorporate honeycomb air flow straighteners to achieve this. Experts note that the accuracy of experimental results can be significantly enhanced when the variables introduced by turbulent air flow are minimized, thus highlighting the essential role of straighteners in experimental rigour and credibility. In terms of construction, the materials chosen for honeycomb air flow straighteners can vary depending on the application, with options ranging from lightweight aluminum to robust composites. Each material offers unique advantages durability, resistance to environmental factors, and cost-effectiveness are all considerations that manufacturers balance based on their specific needs. Professionals involved in product development often conduct thorough analysis and testing to determine the most appropriate material for each application, ensuring the longevity and effectiveness of the component. For industry veterans, the use of honeycomb air flow straighteners does not just stop at the improvement of aerodynamics or energy efficiency. There is also an important consideration regarding their contribution to noise reduction. These devices are pivotal in diminishing aerodynamic noise that can arise from turbulent air flows, thereby providing a quieter and more comfortable environment in both industrial and consumer applications. In conclusion, honeycomb air flow straighteners stand as a testament to the intersection of nature-inspired design and advanced engineering. Their ability to transform chaotic air flows into orderly streams touches on the core of engineering principles - efficiency, reliability, and precision. As technology continues to evolve, the role of these components is likely to grow, further embedding them as an essential tool in our pursuit of performance excellence and sustainability across industries.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025