- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 12:21

Back to list

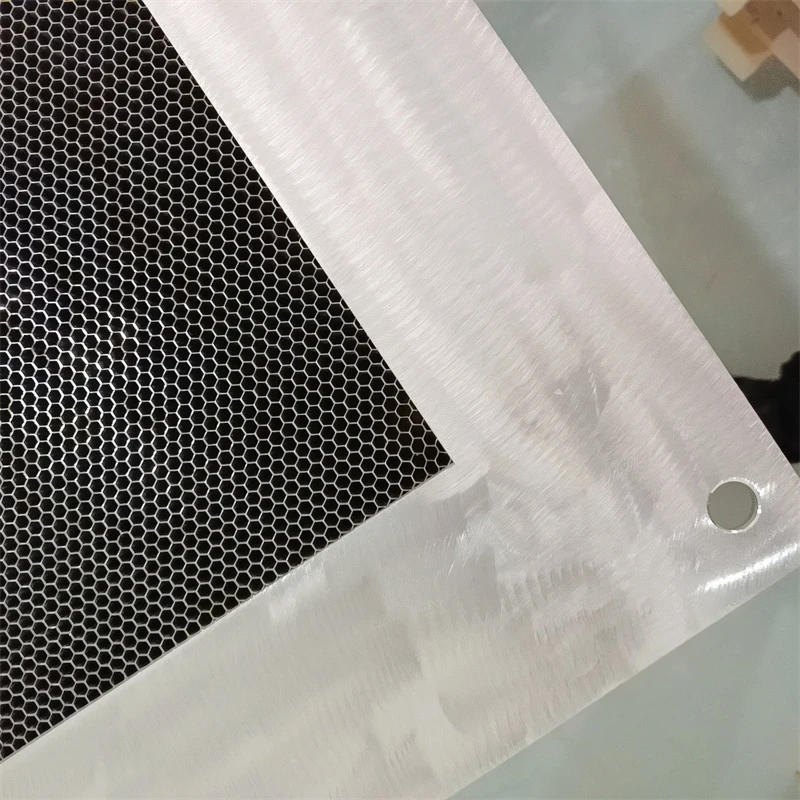

alloy honeycomb sheet

Alloy honeycomb sheets represent a breakthrough in material science, offering unparalleled benefits for various industries. Their unique structure, mimicking the natural geometry of a honeycomb, lends exceptional strength while maintaining lightweight properties. This characteristic is particularly advantageous in aerospace, automotive, and construction sectors, where balancing strength and weight is crucial.

Authoritativeness in this domain stems from extensive research and successful application cases of alloy honeycomb sheets. Numerous studies have verified their mechanical properties and environmental sustainability benefits, placing them at the forefront of eco-friendly materials. For example, the aerospace industry has conducted rigorous testing to confirm these sheets' structural integrity under extreme conditions, further validating their reliability. Leading authorities in materials science advocate for their use across innovative applications, citing long-term durability and adaptability. Trustworthiness is built on the proven track record of alloy honeycomb sheets in demanding applications. Manufacturers and industry leaders prioritize sourcing high-grade alloys and utilizing precision engineering techniques to ensure each sheet meets safety and performance standards. Transparency in supply chain and manufacturing processes strengthens customer confidence, guaranteeing that products are both ethically produced and subjected to stringent quality controls. In conclusion, alloy honeycomb sheets represent a pivotal material innovation with broad applications and proven advantages. Their ability to provide superior structural performance without compromising on weight or sustainability makes them indispensable in advancing modern engineering solutions. Whether in aviation, automotive design, or sustainable architecture, alloy honeycomb sheets offer an unmatched blend of strength, efficiency, and eco-friendliness that professionals across disciplines value highly.

Authoritativeness in this domain stems from extensive research and successful application cases of alloy honeycomb sheets. Numerous studies have verified their mechanical properties and environmental sustainability benefits, placing them at the forefront of eco-friendly materials. For example, the aerospace industry has conducted rigorous testing to confirm these sheets' structural integrity under extreme conditions, further validating their reliability. Leading authorities in materials science advocate for their use across innovative applications, citing long-term durability and adaptability. Trustworthiness is built on the proven track record of alloy honeycomb sheets in demanding applications. Manufacturers and industry leaders prioritize sourcing high-grade alloys and utilizing precision engineering techniques to ensure each sheet meets safety and performance standards. Transparency in supply chain and manufacturing processes strengthens customer confidence, guaranteeing that products are both ethically produced and subjected to stringent quality controls. In conclusion, alloy honeycomb sheets represent a pivotal material innovation with broad applications and proven advantages. Their ability to provide superior structural performance without compromising on weight or sustainability makes them indispensable in advancing modern engineering solutions. Whether in aviation, automotive design, or sustainable architecture, alloy honeycomb sheets offer an unmatched blend of strength, efficiency, and eco-friendliness that professionals across disciplines value highly.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025