- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 12:18

Back to list

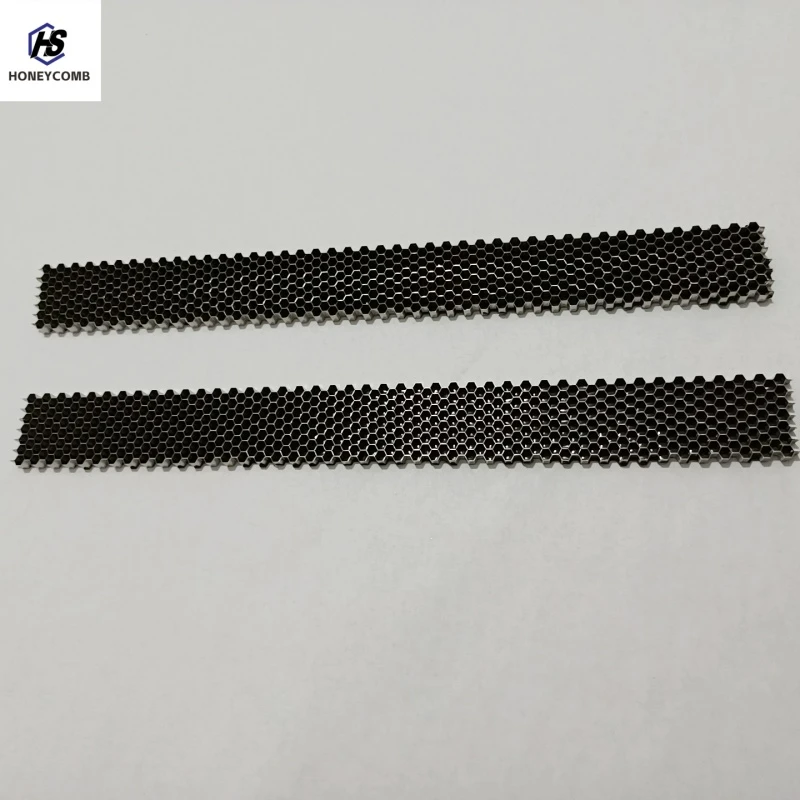

maf honeycomb screen

The innovation of metal honeycomb structures has dramatically influenced various industries, serving as a quintessential example of modern engineering excellence. Emphasizing qualities such as lightweight characteristics, remarkable strength, and superior durability, metal honeycomb materials are transforming applications in automotive, aerospace, and civil engineering sectors. A distinctive aspect of metal honeycomb structures lies in their unique ability to offer exceptional energy absorption capabilities, making them ideal for sectors where safety and resilience are paramount.

The authoritative stance that metal honeycombs hold can be evidenced by their adoption in high-stakes projects, such as aerospace missions where every component must meet the highest trustworthiness and performance standards. The use of these materials in such applications speaks volumes about their reliability and the trust placed in them by industry leaders. Trustworthiness of metal honeycomb structures owes much to their consistent track record of performance. Certified testing and real-world validations have inked their role as dependable solutions in applications requiring flawless performance under duress. Practitioners, clients, and stakeholders exhibit a strong preference for metal honeycombs because they deliver on promises of performance and longevity, proving time and again that their benefits outweigh the initial investment implications. In summary, metal honeycombs encapsulate an intersection of experience, expertise, authoritative development, and trust. Their application not only exemplifies modern technological achievements but also sets a benchmark for future innovations. As new challenges arise in different engineering sectors, the continuous evolution and strategic implementation of metal honeycomb structures remain a testament to the materials’ pivotal role in advancing industries worldwide.

The authoritative stance that metal honeycombs hold can be evidenced by their adoption in high-stakes projects, such as aerospace missions where every component must meet the highest trustworthiness and performance standards. The use of these materials in such applications speaks volumes about their reliability and the trust placed in them by industry leaders. Trustworthiness of metal honeycomb structures owes much to their consistent track record of performance. Certified testing and real-world validations have inked their role as dependable solutions in applications requiring flawless performance under duress. Practitioners, clients, and stakeholders exhibit a strong preference for metal honeycombs because they deliver on promises of performance and longevity, proving time and again that their benefits outweigh the initial investment implications. In summary, metal honeycombs encapsulate an intersection of experience, expertise, authoritative development, and trust. Their application not only exemplifies modern technological achievements but also sets a benchmark for future innovations. As new challenges arise in different engineering sectors, the continuous evolution and strategic implementation of metal honeycomb structures remain a testament to the materials’ pivotal role in advancing industries worldwide.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025