- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 10, 2025 10:03

Back to list

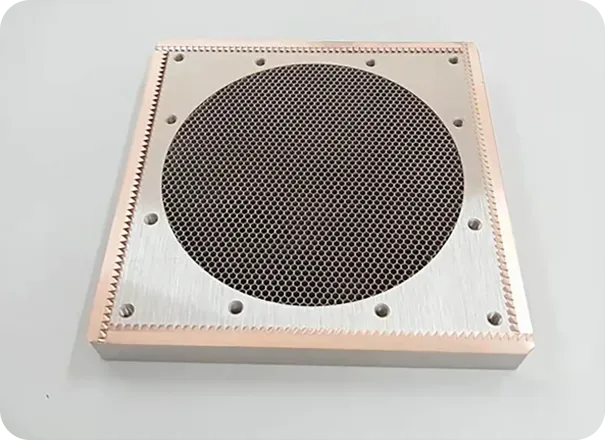

Aluminium Emc Shielded Honeycomb Vent For 120*120mm Fan

Carbon honeycomb cores, an innovative engineering material, revolutionize industries ranging from aerospace to automotive. As an expert in the field of advanced materials, understanding the intricacies of carbon honeycomb cores can generate insights into their widespread applications and the advantages they offer over traditional materials. The unique structure of carbon honeycomb cores consists of interlocking hexagonal cells, reminiscent of a hive's intricate design. This pattern imparts exceptional strength and rigidity while minimizing weight, a crucial factor in high-performance applications where weight savings translate into efficiency gains.

For product manufacturers, integrating carbon honeycomb cores translates into tangible benefits reduced material costs due to lower weight requirements, decreased fuel consumption for transport vehicles, and enhanced product lifecycles through greater durability. Furthermore, the material's resistance to corrosion and environmental wear enhances its appeal for use in long-term infrastructure projects, especially in maritime and coastal applications. Innovation in carbon honeycomb core manufacturing has led to more sustainable production practices, with newer processes focusing on reducing waste and energy consumption. The recyclability of carbon materials presents an environmentally friendly option for end-of-life disposal, aligning with global sustainability goals. Companies investing in this technology gain a competitive edge by aligning their product offerings with environmentally conscious consumer trends. In the realm of sports, athletes benefit from carbon honeycomb cores in equipment that offers precision and performance without sacrificing safety. Cyclists and kayakers, for instance, notice improved aerodynamics and speed due to the reduced weight and increased structural integrity. This advantage allows for enhanced agility and performance, giving athletes the confidence to push their limits. In conclusion, the adoption and exploration of carbon honeycomb cores across diverse industries underscore their unparalleled advantages in strength, weight reduction, and performance capability. These qualities ensure carbon honeycomb cores remain at the forefront of material technology, securing their role in advancing product innovation while promoting sustainability and efficiency. As industries continue to prioritize these cores, the future holds promising developments that will further solidify their status as a cornerstone of modern engineering solutions.

For product manufacturers, integrating carbon honeycomb cores translates into tangible benefits reduced material costs due to lower weight requirements, decreased fuel consumption for transport vehicles, and enhanced product lifecycles through greater durability. Furthermore, the material's resistance to corrosion and environmental wear enhances its appeal for use in long-term infrastructure projects, especially in maritime and coastal applications. Innovation in carbon honeycomb core manufacturing has led to more sustainable production practices, with newer processes focusing on reducing waste and energy consumption. The recyclability of carbon materials presents an environmentally friendly option for end-of-life disposal, aligning with global sustainability goals. Companies investing in this technology gain a competitive edge by aligning their product offerings with environmentally conscious consumer trends. In the realm of sports, athletes benefit from carbon honeycomb cores in equipment that offers precision and performance without sacrificing safety. Cyclists and kayakers, for instance, notice improved aerodynamics and speed due to the reduced weight and increased structural integrity. This advantage allows for enhanced agility and performance, giving athletes the confidence to push their limits. In conclusion, the adoption and exploration of carbon honeycomb cores across diverse industries underscore their unparalleled advantages in strength, weight reduction, and performance capability. These qualities ensure carbon honeycomb cores remain at the forefront of material technology, securing their role in advancing product innovation while promoting sustainability and efficiency. As industries continue to prioritize these cores, the future holds promising developments that will further solidify their status as a cornerstone of modern engineering solutions.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025