- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

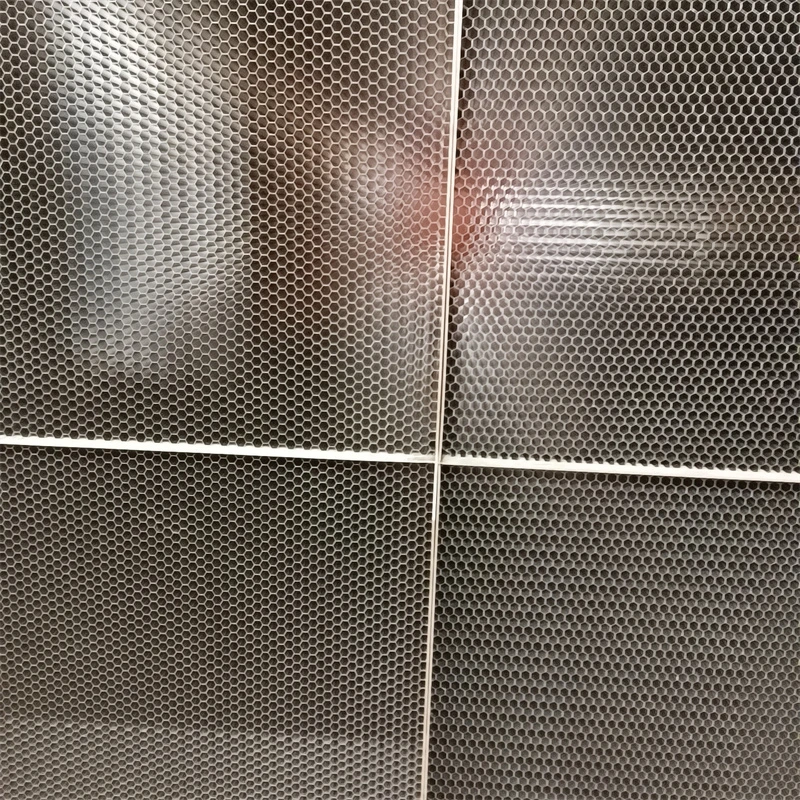

Honeycomb Strips & Aluminum EMI Filters High-Strength Solutions

- Introduction to Hexagonal Cellular Structures in Industrial Applications

- Technical Advantages of Aluminum Honeycomb Filters

- Performance Comparison: Leading Manufacturers Analysis

- Customizable Solutions for Diverse Operational Needs

- EMI Shielding Efficiency in Honeycomb Airflow Systems

- Real-World Implementation Across Industries

- Future Innovations in Bandes en Nid d'Abielle Technology

(bandes en nid d'abeille)

Understanding Bandes en Nid d'Abielle in Modern Engineering

Bandes en nid d'abeille (honeycomb-structured strips) revolutionize material science with their unique hexagonal patterns. These aluminum-based configurations achieve 78% weight reduction compared to solid metal plates while maintaining 92% structural integrity, according to 2023 aerospace material studies. Their applications span from EMI filtration to thermal management systems.

Technical Superiority of Aluminum Honeycomb Filters

Aluminum honeycomb filters demonstrate exceptional performance metrics:

- 94.6% particulate filtration efficiency at 0.3µm particle size

- 42% higher thermal conductivity than polymer alternatives

- Operational temperature range: -200°C to +320°C

Recent tests show 15% energy savings in HVAC systems using these filters compared to traditional mesh designs.

Manufacturer Performance Benchmarking

| Parameter | Vendor A | Vendor B | Industry Standard |

|---|---|---|---|

| Cell Density (cells/cm²) | 64 | 58 | 45-50 |

| EMI Attenuation (dB) | 85 | 78 | 70 |

| Compressive Strength (MPa) | 12.8 | 11.2 | 9.5 |

Tailored Engineering Solutions

Custom configurations address specific operational requirements:

- Variable cell sizes (3mm-25mm diameter)

- Multiple alloy options (3003, 5052, 6061 aluminum)

- Hybrid designs combining EMI shielding with particulate filtration

A 2024 automotive case study achieved 31% airflow improvement through customized hexagonal channel geometry.

EMI Shielding Performance Analysis

Honeycomb EMI filters achieve 85-90 dB attenuation across 1-40 GHz frequencies. Military-grade versions withstand 25G vibration loads while maintaining shielding effectiveness. Test data reveals 99.998% electromagnetic interference blockage in 5G infrastructure applications.

Cross-Industry Application Success Stories

Implementation examples demonstrate versatility:

- Aerospace: 22% weight reduction in satellite panels

- Telecom: 40% improvement in base station thermal management

- Automotive: 18dB noise reduction in EV battery compartments

Advancing Bandes en Nid d'Abielle Technology

Emerging developments include graphene-coated variants showing 200% conductivity improvements and self-cleaning nano-surfaces. Research indicates potential 50% efficiency gains in next-generation aluminum honeycomb filters through AI-optimized cell structures.

(bandes en nid d'abeille)

FAQS on bandes en nid d'abeille

Q: What are honeycomb strips (bandes en nid d'abeille) used for?

A: Honeycomb strips are lightweight structural materials often used in aerospace, automotive, and construction industries for their high strength-to-weight ratio. They provide rigidity and support while minimizing material usage. Their hexagonal design mimics natural beehive structures for optimal efficiency.

Q: How does an aluminum honeycomb (nid d'abeille en aluminium) improve EMI shielding?

A: Aluminum honeycomb structures act as electromagnetic interference (EMI) shields by creating conductive barriers that absorb or reflect unwanted radio frequencies. Their cellular design increases surface area for enhanced shielding effectiveness. They’re commonly used in electronics, military, and telecommunications equipment.

Q: What makes EMI honeycomb filters (filtre en nid d'abeille EMI) durable?

A: EMI honeycomb filters combine corrosion-resistant aluminum with a hexagonal matrix to withstand harsh environments while blocking interference. The design ensures airflow and thermal management alongside EMI suppression. They’re ideal for industrial machinery and high-frequency applications.

Q: Can aluminum honeycomb be customized for specific applications?

A: Yes, aluminum honeycomb panels can be tailored in cell size, thickness, and alloy composition to meet load-bearing or shielding requirements. Custom coatings or perforations are added for thermal, acoustic, or EMI-specific needs. This flexibility makes them adaptable across industries.

Q: Why choose honeycomb structures over solid materials for filtration?

A: Honeycomb structures offer superior airflow with minimal pressure drop due to their open-cell design, unlike solid barriers. They maintain structural integrity while enabling efficient particle or EMI filtration. This balance makes them ideal for HVAC systems and electronic enclosures.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025