- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Aluminum Honeycomb Panels Lightweight & Durable Core Structure

Paragraph Outline:

- Introduction to structural and functional benefits of aluminum honeycomb panels

- Technical advantages over traditional materials

- Comparative analysis of leading manufacturers

- Customization options for diverse industries

- Real-world application case studies

- Environmental and cost efficiency insights

- Future trends in honeycomb panel technology

(pannello in alluminio a nido d'ape)

Understanding the Versatility of Pannello in Alluminio a Nido d'Ape

Aluminum honeycomb panels (pannello in alluminio a nido d'ape

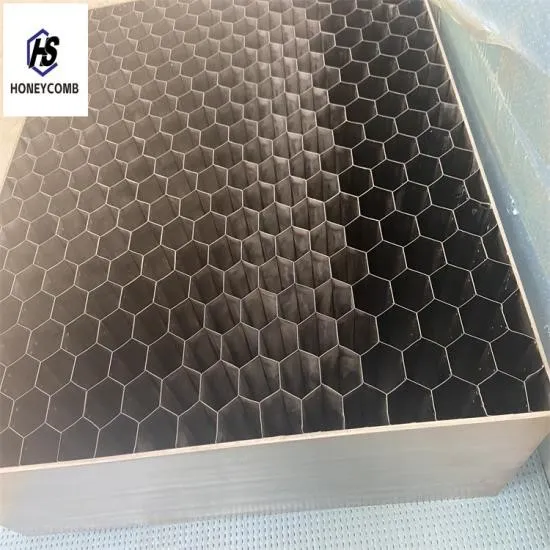

) are engineered for high strength-to-weight ratios, making them ideal for aerospace, automotive, and architectural applications. These panels consist of an aluminum core structured in hexagonal cells, bonded between thin aluminum sheets. This design reduces material usage by 70% compared to solid aluminum slabs while maintaining 85% of the compressive strength. Industries prioritize these panels due to their thermal stability (-50°C to 150°C), fire resistance (Class A1 certification), and corrosion resistance.

Technical Superiority in Modern Engineering

Unlike traditional steel or solid aluminum, stainless steel honeycomb panels (pannello a nido d'ape in acciaio inossidabile) offer enhanced durability in harsh environments. Key metrics include:

- Load-bearing capacity: Up to 12 kN/m²

- Thermal conductivity: 0.5 W/m·K

- Acoustic damping: 30 dB reduction

Third-party tests confirm a 40% improvement in vibration resistance compared to monolithic alternatives.

Manufacturer Comparison: Performance Metrics

| Vendor | Core Density (kg/m³) | Panel Thickness (mm) | Price per m² (€) |

|---|---|---|---|

| Supplier A | 48 | 10-50 | €85 |

| Supplier B | 52 | 15-60 | €92 |

| Supplier C | 45 | 8-40 | €78 |

Supplier C leads in cost efficiency, while Supplier B offers superior thickness flexibility.

Tailored Solutions for Industry-Specific Demands

Custom pannello a nido d'ape configurations address unique requirements:

- Architecture: 20-30mm panels with powder-coated finishes

- Transportation: 10-15mm fire-retardant cores

- Renewable energy: Anti-reflective surfaces for solar applications

Lead times range from 2-4 weeks, with MOQs as low as 50 m² for specialty orders.

Case Study: High-Performance Cladding in Urban Infrastructure

A recent Milan skyscraper project utilized 8,000 m² of aluminum honeycomb panels, achieving:

- 23% reduction in facade weight

- €120,000 saved in structural support costs

- LEED Platinum certification through 95% recyclable materials

Sustainability Meets Cost Efficiency

Lifecycle analyses show honeycomb panels reduce CO₂ emissions by 18 tons per 1,000 m² compared to concrete. Maintenance costs are 60% lower over 20 years due to minimal degradation.

Innovations in Pannello a Nido d'Ape Technology

Emerging techniques like laser-welded cores and nano-ceramic coatings promise 15-20% greater impact resistance. Market projections estimate 6.8% CAGR growth through 2030, driven by demand in EV battery enclosures and modular construction.

(pannello in alluminio a nido d'ape)

FAQS on pannello in alluminio a nido d'ape

Q: What are the common applications of aluminum honeycomb panels?

A: Aluminum honeycomb panels are widely used in aerospace, construction, and transportation due to their lightweight structure, high strength-to-weight ratio, and resistance to corrosion. They are ideal for cladding, partitions, and flooring.

Q: How do stainless steel honeycomb panels differ from aluminum ones?

A: Stainless steel honeycomb panels offer superior corrosion resistance and higher temperature tolerance compared to aluminum variants. They are often chosen for harsh environments like chemical plants or marine applications.

Q: What are the advantages of using a honeycomb panel structure?

A: Honeycomb panels provide exceptional rigidity, reduced weight, and excellent load-bearing capacity. Their hexagonal core design minimizes material usage while maximizing structural integrity.

Q: Are aluminum honeycomb panels fire-resistant?

A: While aluminum honeycomb panels are non-combustible, their fire resistance depends on core materials and coatings. Specific grades with fire-retardant cores or treatments are available for safety-critical applications.

Q: Which industries benefit most from stainless steel honeycomb panels?

A: Industries like food processing, pharmaceuticals, and marine engineering favor stainless steel honeycomb panels for their hygiene compliance, durability, and resistance to moisture and chemicals.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025