- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 17, 2025 03:32

Back to list

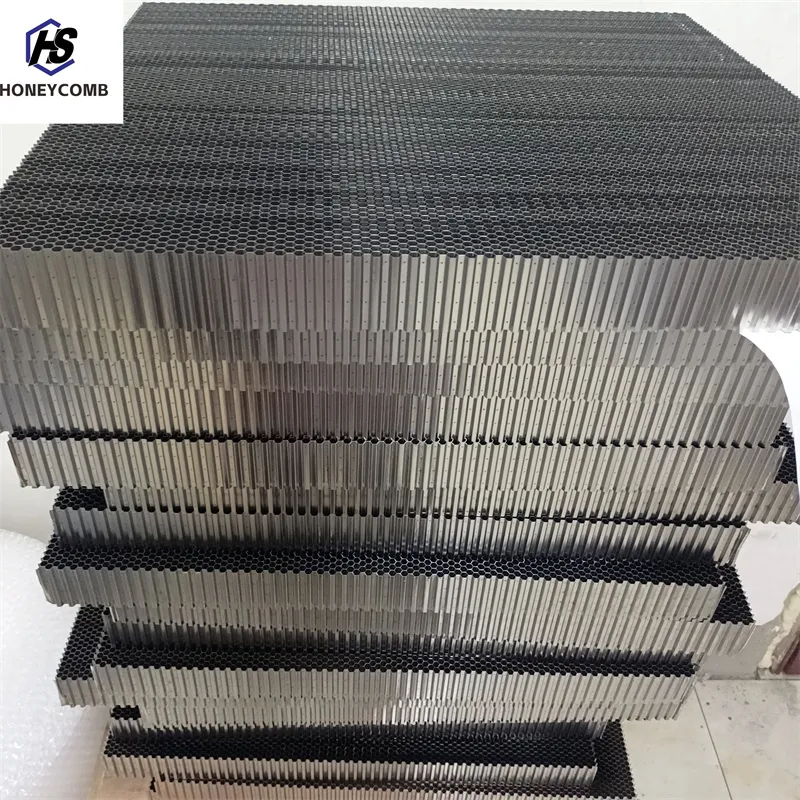

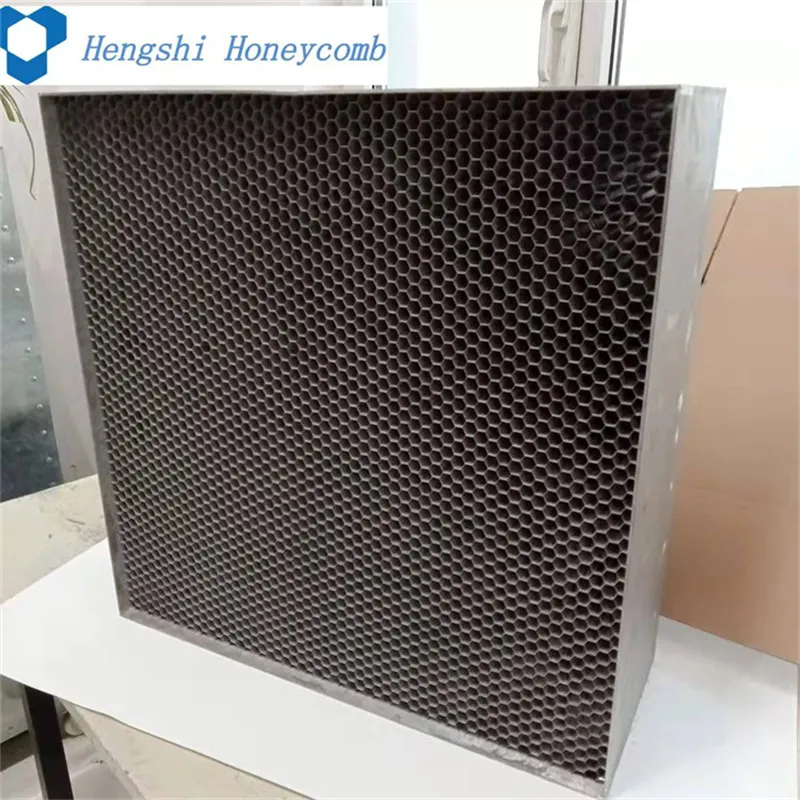

emi honeycomb

The honeycomb band, often referred to in the industry with its French term bandes en nid d'abeille, stands as a pivotal element in various sectors due to its unique combination of durability, flexibility, and light-weight characteristics. This specialized product continues to gain traction for its versatile applications, ranging from industrial uses to artistic endeavors.

Experts in the field appreciate the technical nuances that make honeycomb bands an industry standard. Specialists often engage in continuous testing and innovation, seeking out novel materials and coatings that further enhance these bands' properties. Such advancements have paved the way for the integration of honeycomb bands in fields like wind energy, where they are used in turbine blade design to balance strength and weight – an essential factor in efficient energy generation. Given their widespread and varied application, honeycomb bands are a topic of continued research and development. The push towards sustainability has seen a rise in the use of biodegradable materials in their manufacture, which aligns with global environmental initiatives. This focus not only highlights the adaptability of honeycomb technology but also underscores the industry's commitment to reducing environmental impact without compromising on performance. Trust in honeycomb band products is bolstered by certifications and compliance with international standards. Leading manufacturers ensure that their products undergo rigorous testing to meet the demands of their use cases, reinforcing their authority in the market. For consumers and businesses, this translates to confidence in the product's reliability, backed by years of expertise and a track record of proven results. In summary, the honeycomb band represents a convergence of design ingenuity and functional excellence. Its broad adoption across multiple industries attests to its versatility and the high regard in which it is held by professionals who recognize its tangible benefits. As technology advances, the potential for honeycomb bands continues to unfold, promising further innovations that harmonize with the needs of an evolving world.

Experts in the field appreciate the technical nuances that make honeycomb bands an industry standard. Specialists often engage in continuous testing and innovation, seeking out novel materials and coatings that further enhance these bands' properties. Such advancements have paved the way for the integration of honeycomb bands in fields like wind energy, where they are used in turbine blade design to balance strength and weight – an essential factor in efficient energy generation. Given their widespread and varied application, honeycomb bands are a topic of continued research and development. The push towards sustainability has seen a rise in the use of biodegradable materials in their manufacture, which aligns with global environmental initiatives. This focus not only highlights the adaptability of honeycomb technology but also underscores the industry's commitment to reducing environmental impact without compromising on performance. Trust in honeycomb band products is bolstered by certifications and compliance with international standards. Leading manufacturers ensure that their products undergo rigorous testing to meet the demands of their use cases, reinforcing their authority in the market. For consumers and businesses, this translates to confidence in the product's reliability, backed by years of expertise and a track record of proven results. In summary, the honeycomb band represents a convergence of design ingenuity and functional excellence. Its broad adoption across multiple industries attests to its versatility and the high regard in which it is held by professionals who recognize its tangible benefits. As technology advances, the potential for honeycomb bands continues to unfold, promising further innovations that harmonize with the needs of an evolving world.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025