- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 17, 2025 03:54

Back to list

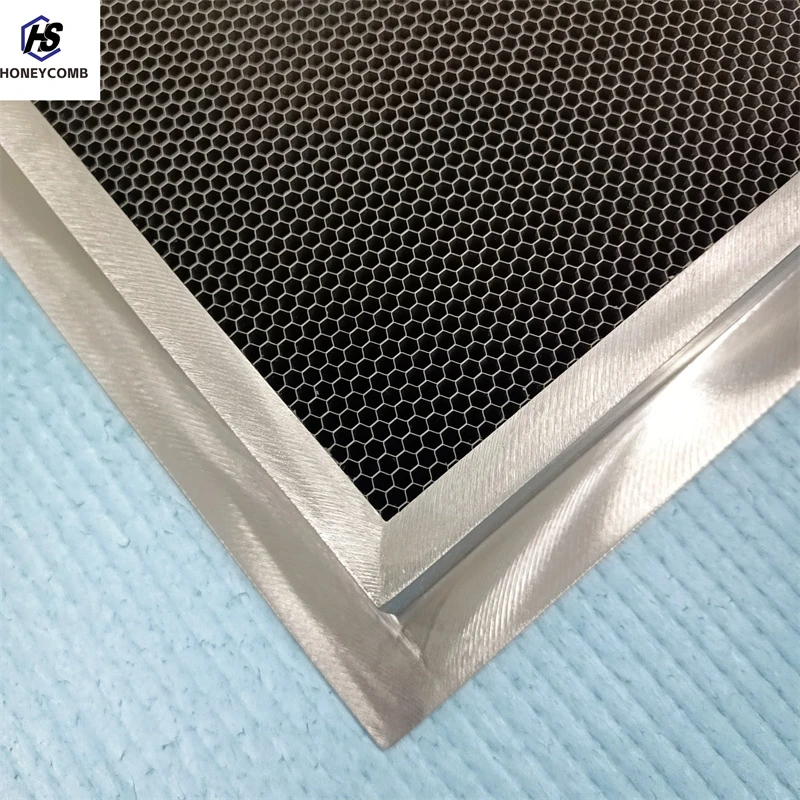

honeycomb panel

Honeycomb joints have been gaining significant attention in the construction and engineering sectors due to their unique structure and versatile applications. Famously inspired by nature, the honeycomb pattern is not only aesthetically pleasing but also packs a punch in terms of functionality. This geometric shape, characterized by its hexagonal cells, is renowned for offering high strength-to-weight ratios, making it an optimal choice for various industrial applications.

When considering honeycomb joints, their authority in sustainable construction practices cannot be overlooked. The production of these joints often involves materials that are recyclable or derived from eco-friendly sources. This not only minimizes the environmental footprint but also often results in a more cost-effective solution for long-term projects. As sustainable construction continues to dominate industry trends, honeycomb structures are cementing their role as leading components in eco-conscious architectural designs. Trust in honeycomb joints is built on a rich history of success across multiple fields. Their application in industries where failure is not an option speaks volumes about their reliability. For example, in automotive engineering, honeycomb crash absorption panels are a critical component that protects passengers by effectively dissipating energy during a collision. Likewise, in marine engineering, their use in ship hulls helps enhance buoyancy and resistance to harsh sea conditions. In conclusion, honeycomb joints exemplify the intersection of nature's design brilliance with human engineering capability. Their multifaceted applications highlight an essential blend of experience, expertise, authority, and trustworthiness. As industries continue to evolve, the adoption of advanced materials and structures like honeycomb joints will remain a pivotal factor in advancing technology and sustainability in construction and engineering. With ongoing research and technological advancements, the future holds promising potential for even more innovative applications of honeycomb joints across various domains.

When considering honeycomb joints, their authority in sustainable construction practices cannot be overlooked. The production of these joints often involves materials that are recyclable or derived from eco-friendly sources. This not only minimizes the environmental footprint but also often results in a more cost-effective solution for long-term projects. As sustainable construction continues to dominate industry trends, honeycomb structures are cementing their role as leading components in eco-conscious architectural designs. Trust in honeycomb joints is built on a rich history of success across multiple fields. Their application in industries where failure is not an option speaks volumes about their reliability. For example, in automotive engineering, honeycomb crash absorption panels are a critical component that protects passengers by effectively dissipating energy during a collision. Likewise, in marine engineering, their use in ship hulls helps enhance buoyancy and resistance to harsh sea conditions. In conclusion, honeycomb joints exemplify the intersection of nature's design brilliance with human engineering capability. Their multifaceted applications highlight an essential blend of experience, expertise, authority, and trustworthiness. As industries continue to evolve, the adoption of advanced materials and structures like honeycomb joints will remain a pivotal factor in advancing technology and sustainability in construction and engineering. With ongoing research and technological advancements, the future holds promising potential for even more innovative applications of honeycomb joints across various domains.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025