- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 17, 2025 04:18

Back to list

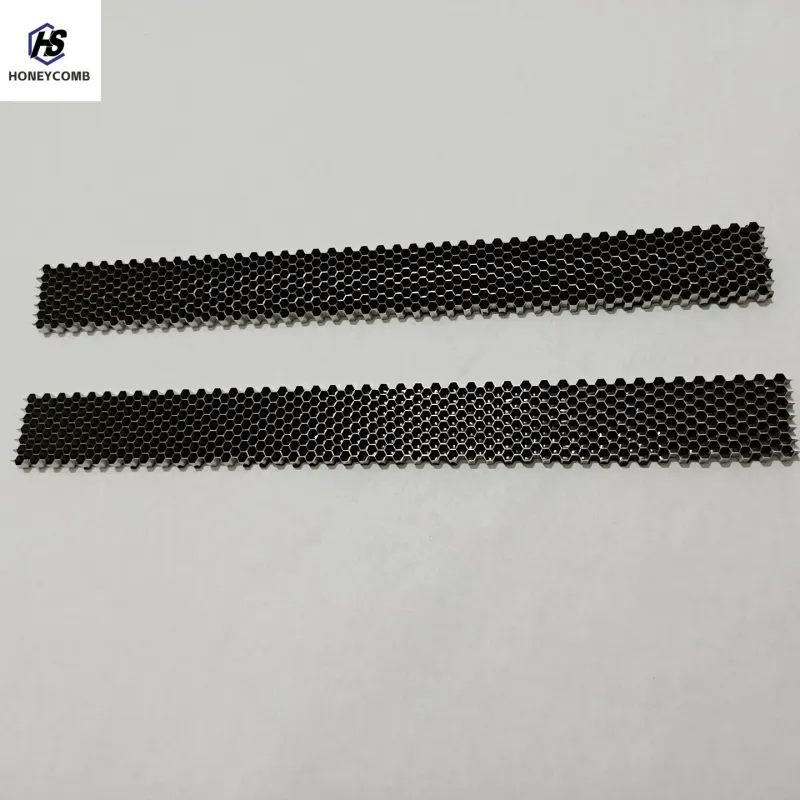

Stainless Steel 1/8mm EMI/EMC/RF Shielded Honeycomb Vent

In the world of interior design and architecture, the term joint en nid d'abeille often emerges, especially for those seeking innovative solutions that transcend traditional aesthetics. This sophisticated technique, translated as honeycomb joint, is both a testament to human ingenuity and a solution that marries form with function. Rooted in both ancient architecture and modern innovation, honeycomb joints have become the cornerstone of creating structures that are not only visually appealing but also exceptionally sturdy and sustainable.

Trustworthiness in this context is built on consistency and the proven track record of honeycomb joints in challenging applications. Clients—be they corporate, public sector, or residential—often seek reassurance in past successes before committing to newer methods. Case studies well-documented in architectural journals and engineering reports provide a wealth of information validating the reliability of honeycomb joints. Moreover, the growing body of work showcasing successful projects around the world further instills confidence, showing not just theoretical potential but practical, real-world effectiveness. The journey from conceptualization to reality with a honeycomb joint design involves several key steps that ensure both optimal performance and adherence to clients' aesthetic preferences. Initial stages include in-depth consultations with structural engineers and material scientists to determine the best materials and configurations for the specific demands of the project. This collaboration between experts is pivotal, ensuring that each honeycomb structure is tailored precisely to meet the requirements it must fulfill. Furthermore, ongoing advancements in technology, particularly in 3D printing and computational modeling, have dramatically expanded the possibilities for honeycomb structures. These technologies allow for unprecedented precision in design and manufacturing, minimizing tolerances and maximizing structural integrity. As a result, projects can now achieve levels of personalization and innovation that were previously unattainable, offering unique solutions that perfectly align with the client’s vision. In conclusion, the allure of the honeycomb joint lies in its ability to seamlessly integrate cutting-edge design with practical functionality. It stands as a synthesis of nature's wisdom and human innovation, offering solutions that are at once beautiful, efficient, and sustainable. As more professionals and enthusiasts discover the benefits of this ingenious joint, the future of architecture and design will undoubtedly continue to evolve, driven by these fundamental principles of strength, sustainability, and synergy between tradition and the avant-garde.

Trustworthiness in this context is built on consistency and the proven track record of honeycomb joints in challenging applications. Clients—be they corporate, public sector, or residential—often seek reassurance in past successes before committing to newer methods. Case studies well-documented in architectural journals and engineering reports provide a wealth of information validating the reliability of honeycomb joints. Moreover, the growing body of work showcasing successful projects around the world further instills confidence, showing not just theoretical potential but practical, real-world effectiveness. The journey from conceptualization to reality with a honeycomb joint design involves several key steps that ensure both optimal performance and adherence to clients' aesthetic preferences. Initial stages include in-depth consultations with structural engineers and material scientists to determine the best materials and configurations for the specific demands of the project. This collaboration between experts is pivotal, ensuring that each honeycomb structure is tailored precisely to meet the requirements it must fulfill. Furthermore, ongoing advancements in technology, particularly in 3D printing and computational modeling, have dramatically expanded the possibilities for honeycomb structures. These technologies allow for unprecedented precision in design and manufacturing, minimizing tolerances and maximizing structural integrity. As a result, projects can now achieve levels of personalization and innovation that were previously unattainable, offering unique solutions that perfectly align with the client’s vision. In conclusion, the allure of the honeycomb joint lies in its ability to seamlessly integrate cutting-edge design with practical functionality. It stands as a synthesis of nature's wisdom and human innovation, offering solutions that are at once beautiful, efficient, and sustainable. As more professionals and enthusiasts discover the benefits of this ingenious joint, the future of architecture and design will undoubtedly continue to evolve, driven by these fundamental principles of strength, sustainability, and synergy between tradition and the avant-garde.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025