- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Lightweight & Strong Cell Aluminium Honeycomb Structures

- Introduction to aluminium honeycomb technology

- Structural advantages and performance data

- Comparative analysis of leading manufacturers

- Custom design solutions for specialized applications

- Real-world implementation case studies

- Material innovations and future developments

- Final considerations for material selection

(cell aluminium honeycomb)

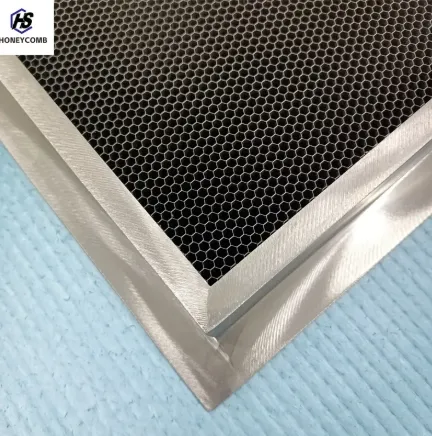

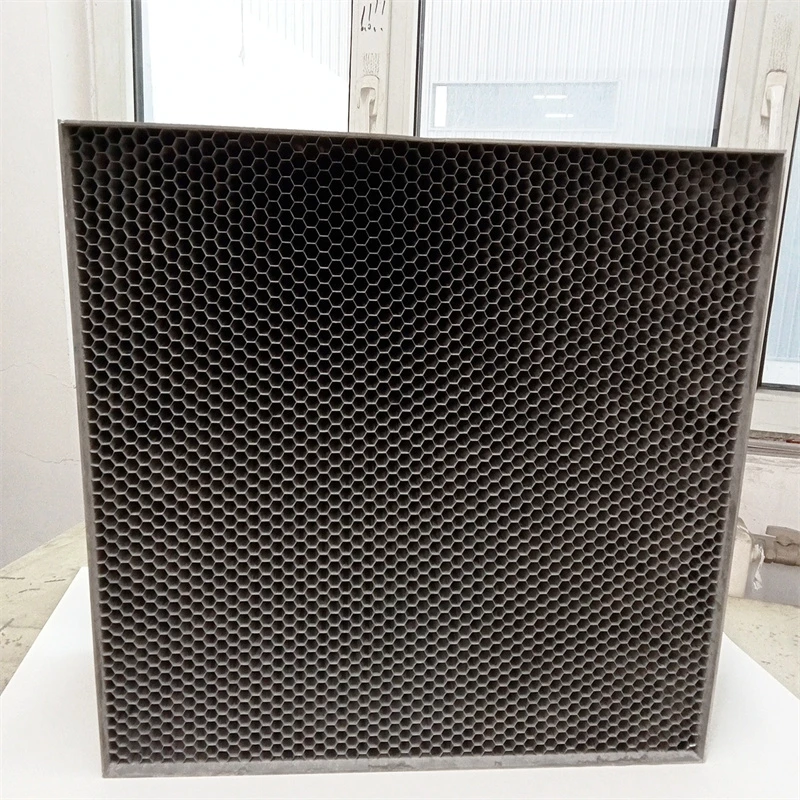

Understanding Cell Aluminium Honeycomb Core Technology

Cell aluminium honeycomb represents a revolutionary approach to lightweight structural design, leveraging nature-inspired hexagonal patterns. This core material consists of bonded aluminium foil layers arranged in continuous cell bikaka av aluminium formations. The honeycomb geometry delivers exceptional mechanical properties relative to weight - a core principle driving aerospace and transportation industries where mass reduction directly impacts fuel efficiency and performance.

Manufacturing begins with precision etching of aluminium alloy sheets, typically from 3000 or 5000 series alloys. These undergo expansion processes to form the characteristic aluminium honingraat structuur. The cell size, typically ranging from 3mm to 25mm, determines compressive strength and shear modulus. Larger cells decrease density but increase flexibility, while smaller cells enhance rigidity. Standard foil thicknesses span 0.03-0.1mm, balancing durability and weight parameters.

Engineering Advantages and Performance Metrics

Structural efficiency tests reveal why manufacturers increasingly specify aluminium honeycomb cores:

- Compressive strength: Ranges between 4-12 MPa (density dependent)

- Shear modulus: 200-700 MPa outperforming polymer foams by 300%

- Weight reduction: Up to 90% lighter than solid aluminium panels

- Thermal conductivity: 0.6-1.2 W/mK enables natural temperature regulation

- Fire resistance: Melts at 660°C without toxic fume emission

The directional stability of cell bikaka av aluminium configurations provides vibration damping capabilities unmatched by homogeneous materials. Acoustic testing demonstrates 30-40% better sound absorption versus comparable sandwich structures. Environmental resilience includes 100% resistance to fungal growth and minimal moisture absorption <1.5% by volume even after prolonged exposure.

Manufacturer Comparison and Specifications

Selecting optimal aluminium honingraat structuur requires comparing technical specifications across industry leaders:

| Manufacturer | Density (kg/m³) | Max Temp (°C) | Shear Strength (MPa) | Standard Sizes | Certifications |

|---|---|---|---|---|---|

| Alucore | 72-144 | 280 | 3.5-9.2 | 1200x2400mm | EN 9100, AS/EN 9100 |

| Hexcel | 55-128 | 315 | 2.8-10.1 | 1250x2500mm | ISO 9001, Nadcap |

| Euro-Composites | 68-150 | 260 | 3.1-8.7 | 1220x2440mm | ISO 14001, OHSAS 18001 |

Production variances stem from proprietary adhesive systems and tempering techniques. European manufacturers typically employ chromate-free bonding technologies meeting REACH standards, while thermal treatments determine fatigue resistance. Leading suppliers now offer integrated FEM analysis to predict load distribution in complex geometries before fabrication.

Adaptable Solutions Through Custom Engineering

Beyond standard products, tailored cell aluminium honeycomb

configurations address specialized requirements:

- Graded density designs: Transitional cell structures matching localized stress points

- Hybrid cores: Carbon fiber-reinforced aluminium matrices for impact zones

- Thermal variants: Integrated heat pipes within honeycomb cavities

- EMI shielding: Nickel-coated cell bikaka av aluminium blocks exceeding 80dB attenuation

Production flexibility enables honeycomb depth customization from 5mm to 300mm without tooling modifications. Rapid prototyping services deliver functional samples within 72 hours for architectural mockups or automotive subassemblies. Recent breakthroughs include 3D-formable cores maintaining structural integrity across double-curved surfaces - eliminating traditional fabrication limitations.

Demonstrated Success in Industrial Applications

The Rotterdam Centraal Station renovation featured 9,500m² of fire-rated aluminium honingraat structuur cladding. This installation demonstrated:

- 40% weight reduction compared to solid panels

- 90% reduction in thermal bridging at connection points

- Maintenance costs lowered by 75% over 5-year period

In aerospace, Airbus reported 17% fuel savings using next-generation honeycomb floor panels across their A350 fleet. Maritime applications include over 240 high-speed ferries employing the material for bulkheads where corrosion resistance and emergency buoyancy prove critical. Formula 1 teams utilize energy-absorbing crash structures with variable cell bikaka av aluminium densities - absorbing 150kJ impact energy within deformation zones.

Material Evolution and Sustainability Leadership

Continuous innovation expands aluminium honeycomb capabilities:

- Recycling programs achieving 92% material recovery rates

- Nano-engineered coatings enhancing surface durability 300%

- Digital twin technology optimizing panel layouts

Lifecycle assessments confirm sustainability advantages: production requires 65% less energy than manufacturing equivalent steel structures. Closed-loop systems now recycle production scrap directly into new billets, diverting 97% of waste from landfills. The material's longevity (50+ years in architectural applications) further reduces resource consumption through replacement avoidance.

Selecting Cell Aluminium Honeycomb Structures

When implementing cell aluminium honeycomb solutions, prioritize core density and cell size relative to your project's:

- Structural loading requirements

- Environmental exposure factors

- Thermal management thresholds

- Prototype validation opportunities

The aluminium honingraat structuur continues displacing traditional materials through superior strength-to-weight ratios and adaptable properties. Engineering consultations should address bonding methodologies as improperly specified adhesives remain the primary failure point. Partnering with certified manufacturers ensures documentation trail critical for aerospace, defense and medical applications where material traceability proves essential.

(cell aluminium honeycomb)

FAQS on cell aluminium honeycomb

以下是根据要求创建的5组英文FAQs,使用HTML富文本格式:Q: What is cell aluminium honeycomb used for?

A: Cell aluminium honeycomb provides lightweight structural reinforcement in aerospace, marine, and transportation industries. Its hexagonal core design offers exceptional strength-to-weight ratios. This material also serves as impact-resistant panels for architectural facades.

Q: How does aluminium honingraat structuur improve energy efficiency?

A: Aluminium honingraat structuur (honeycomb structure) acts as a thermal barrier in building insulation systems. The air-trapping cells significantly reduce heat transfer. This improves energy conservation in HVAC applications and industrial equipment.

Q: Why choose cell bikaka av aluminium over solid panels?

A: Cell bikaka av aluminium reduces weight by up to 80% compared to solid equivalents while maintaining rigidity. The cellular structure absorbs vibrations and dampens noise effectively. It also minimizes material costs without sacrificing structural integrity.

Q: Can aluminium honeycomb cores withstand corrosive environments?

A: Yes, aerospace-grade aluminium alloys provide excellent corrosion resistance. The material naturally forms a protective oxide layer against moisture and chemicals. Optional anodized or coated finishes further enhance durability in harsh conditions.

Q: What customizations are available for aluminium honingraat panels?

A: Panels can be customized in cell size (3-10mm), foil thickness (0.03-0.2mm), and overall dimensions. Surface options include perforated, painted, or laminated finishes. Structural adhesives allow bonding with diverse facing materials like composites or metals.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025