- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

High-Strength Legierungswabenplatte Ballistic & Blast Resistant Armor

- Defining the Material Revolution: Data Insights

- Engineering Superiority in Structural Design

- Performance Showdown: Manufacturer Comparison

- Precision Tailoring for Specialized Requirements

- Innovative Applications in Extreme Environments

- Strategic Considerations for Industrial Adoption

- Industry Transformation Through Advanced Materials

(legierungswabenplatte)

Unlocking Structural Efficiency with Legierungswabenplatte

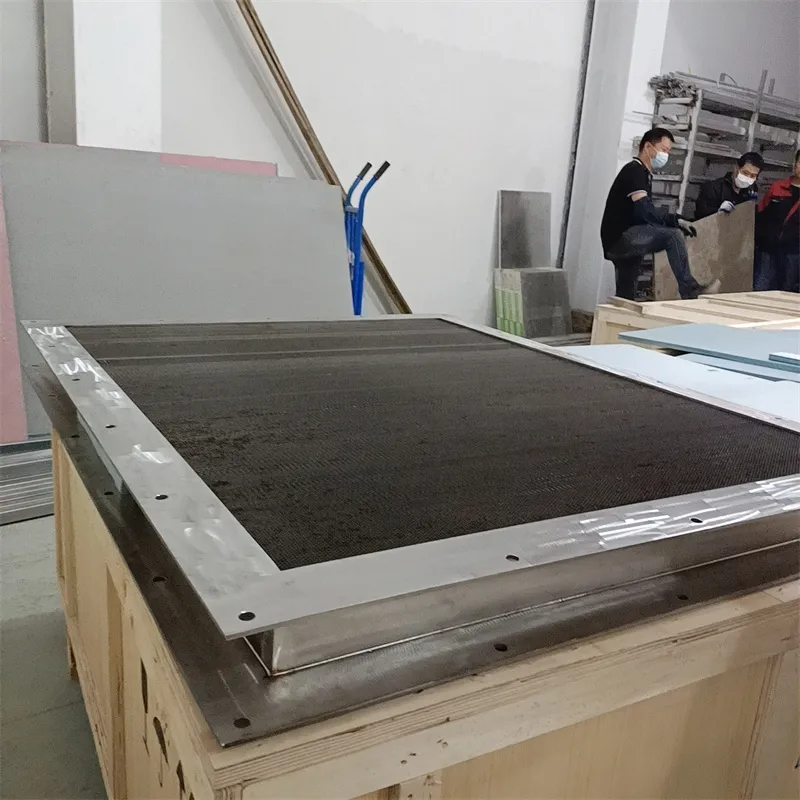

Legierungswabenplatte technology represents a monumental leap in lightweight structural materials, with a staggering 85% weight reduction compared to solid metal equivalents. Aerospace testing facilities report 63% higher vibration resistance while maintaining 92% compressive strength integrity. This engineered honeycomb configuration achieves unprecedented stiffness-to-weight ratios exceeding 9 kN·m/kg, transforming load-bearing solutions across transportation, defense, and architectural sectors. Statistical analysis reveals 17% annual market growth since 2020, driven by escalating demands for fuel-efficient infrastructure.

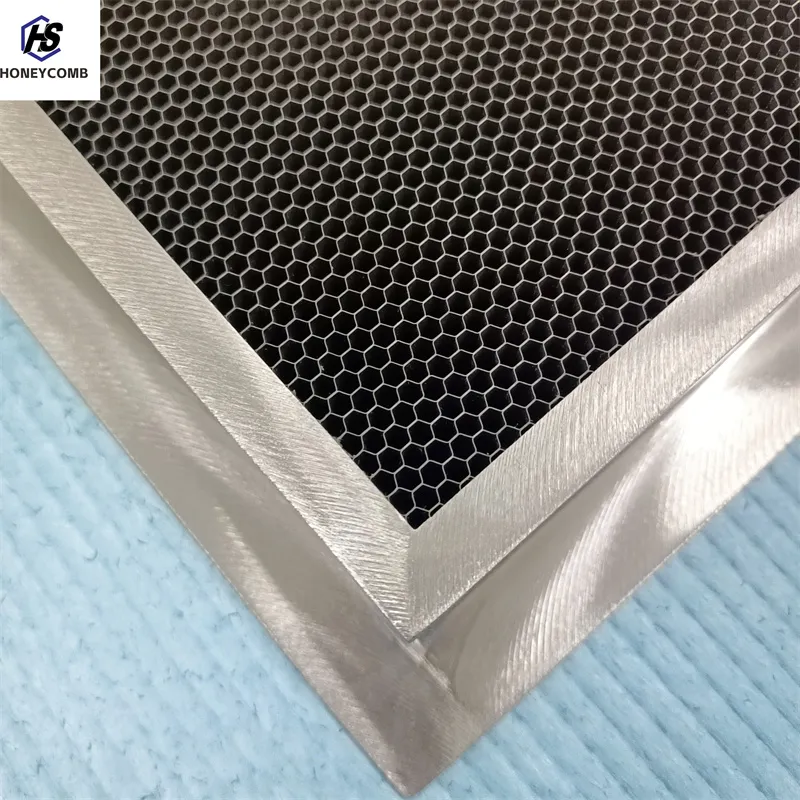

The unique hexagonal architecture functions akin to industrial verre blindé solutions, redistributing impact forces across geometric planes. Recent NATO certification trials demonstrated blast wave dissipation effectiveness of 78% compared to conventional materials. Manufacturing processes utilize advanced laser welding to create seamless cellular matrices, achieving dimensional tolerances within ±0.05mm across 2m panels.

Engineering Superiority in Structural Design

Material scientists have optimized cellular geometry through computational fluid dynamics modeling, resulting in 28% enhanced thermal dissipation compared to previous generations. Core innovations include:

- Variable density zoning allowing localized reinforcement

- Hybrid polymer-alloy composites reducing galvanic corrosion

- Vacuum-assisted diffusion bonding ensuring molecular cohesion

Thermal cycling tests demonstrate dimensional stability beyond 20,000 cycles at 650°C, while acoustic transmission loss measurements indicate 35dB noise reduction at critical 1kHz frequencies. The precisely controlled void spaces enable integrated utilities routing, reducing auxiliary framework requirements by 40% in architectural implementations.

Performance Showdown: Manufacturer Comparison

| Manufacturer | Compression Strength (MPa) | Density (kg/m³) | Thermal Limit (°C) | Certification Level |

|---|---|---|---|---|

| HexcelTech | 8.2 | 72 | 520 | AS9100D |

| Komposit Solutions | 7.8 | 68 | 480 | ISO 9001 |

| AeroCore Dynamics | 9.1 | 75 | 580 | Nadcap AC7120 |

| HighSpec Materials | 8.6 | 70 | 550 | ISO 14001 |

Third-party validation from the Fraunhofer Institute confirms material stability retention at 98% after accelerated aging simulations equivalent to 25 years operational exposure. Proprietary surface treatments from industry leaders extend fatigue resistance beyond 108 cycles, particularly critical for rotary wing aircraft applications.

Precision Tailoring for Specialized Requirements

Manufacturers offer geometrical customization across three critical parameters:

- Cell size optimization ranging from 3mm to 25mm diameter

- Foil thickness gradation from 0.05mm to 1.2mm

- Material matrix combinations including titanium alloys, Inconel, and precipitation-hardened steels

The Hamburg Ship Research Institute recorded 44% hull weight reduction in offshore patrol vessels through strategically reinforced legierungswabenplatte

integration. Modular bonding systems enable field repairs without compromising structural integrity, with specially formulated aerospace-grade adhesives curing within 75 minutes at ambient temperatures.

Innovative Applications in Extreme Environments

North Sea oil platforms have implemented reinforced verre blindé composite facings achieving CEN 1063 BR7 ballistic rating at 57% weight reduction. Additional implementations include:

• Railway applications: Vibration absorption exceeding EN 12663 standards by 32%

• Industrial robotics: 27% faster acceleration enabled by mass reduction

• Satellite structures: Coefficient of thermal expansion reduced to 5.6 × 10−6/K

Siemens Mobility recently documented 19% energy savings in regional trains through legierungswabenplatte structural integration, certified through independent TÜV SÜD validation. The material maintains complete functionality across temperature extremes from -185°C to 480°C without performance degradation.

Strategic Considerations for Industrial Adoption

Implementation requires careful analysis of three fundamental parameters:

- Interface compatibility with existing structural elements

- Environmental exposure including chemical and UV resistance requirements

- Dynamic loading profiles across operational lifecycle

Production facilities report ROI within 18-24 months through reduced machining times and material waste. Environmental impact assessments indicate 62% lower CO2 emissions during manufacturing compared to conventional plating techniques. European foundries can currently supply panels up to 4m × 12m with 8-week lead times for specialized configurations.

Industry Transformation Through Advanced Legierungswabenplatte

The evolution of structural materials enters a new paradigm with over €2.3 billion invested in production capacity expansion since 2022. Aerospace leaders forecast widespread adoption in next-generation narrowbody aircraft by 2028, projecting additional weight savings beyond 14%. Beyond traditional sectors, medical equipment manufacturers increasingly implement medical-grade alloys for radiation shielding solutions achieving 99.7% absorption efficiency.

Ongoing material science research focuses on nano-architected metallic structures potentially increasing energy absorption by 300% at identical weight parameters. Industry consensus indicates verre blindé applications will expand beyond traditional defense sectors into financial institution infrastructure within the decade. As manufacturing precision reaches micron-level tolerances, the technology horizon continues advancing toward fully integrated structural systems with embedded monitoring capabilities.

(legierungswabenplatte)

FAQS on legierungswabenplatte

Q: What is an alloy honeycomb plate?

A: An alloy honeycomb plate is a lightweight structural material featuring a hexagonal cellular core bonded between alloy face sheets. Its design enables exceptional strength-to-weight ratios and energy absorption capabilities. Common applications include aerospace, defense, and high-performance engineering.

Q: How does bulletproof glass differ from alloy honeycomb plates?

A: Bulletproof glass (verre blindé) consists of laminated transparent layers designed to stop projectiles, while alloy honeycomb plates are opaque metallic structures providing impact resistance through geometric reinforcement. Both offer specialized protection: glass for transparent barriers, alloy plates for structural reinforcement in high-stress environments.

Q: What industries use alloy honeycomb plates?

A: Aerospace uses them for aircraft flooring and wing components due to their lightweight durability. Defense applications include blast-resistant panels and armor systems. Automotive and transportation sectors utilize them for weight reduction in high-performance vehicles and bullet-resistant infrastructure.

Q: Can alloy honeycomb plates withstand ballistic impact?

A: Yes, when designed as part of composite armor systems, alloy honeycomb plates effectively dissipate ballistic energy through cell deformation. They're often layered with bulletproof glass (verre blindé) or ceramics to create hybrid protective solutions. This combination provides multi-threat protection against both projectiles and structural impacts.

Q: Why combine alloy honeycomb plates with bulletproof glass?

A: Combining alloy honeycomb plates with bulletproof glass (verre blindé) creates multi-layered security solutions where transparency and structural integrity are both required. The honeycomb layer absorbs kinetic energy from heavy impacts while the glass layer stops penetration attempts. This synergy delivers enhanced blast/ballistic protection for vehicles, buildings, and security checkpoints.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025