- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

cell aluminium honeycomb

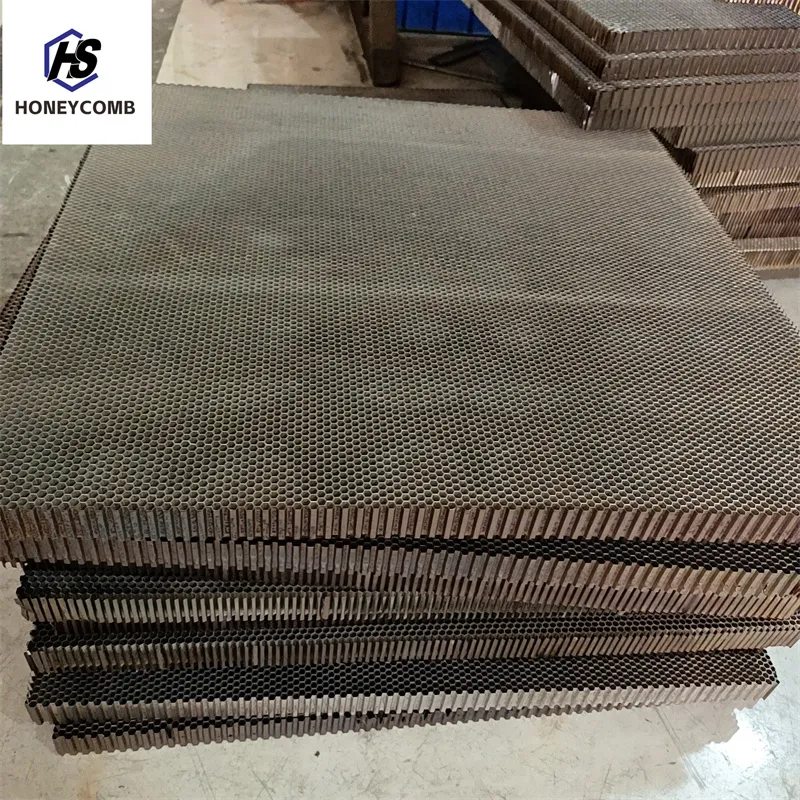

Cell aluminium honeycomb structures have rapidly become a cornerstone in modern engineering applications, celebrated for their lightweight yet robust characteristics. These structures, akin to natural honeycombs, are manufactured using aluminium due to its incredible strength-to-weight ratio, corrosion resistance, and thermal conductivity. This article delves into the transformative benefits and notable applications of cell aluminium honeycomb structures, underscoring their unmatched efficiency across various industries.

Present-day advancements in material science have propelled cell aluminium honeycomb designs to the forefront of innovation, primarily owing to their versatile engineering applications. These honeycomb panels, characterized by hexagonal cells, deliver unparalleled strength while maintaining a light physical profile. This unique property is a game-changer for industries looking to optimize structural efficiency without compromising on durability or strength.

One of the most compelling real-world applications of cell aluminium honeycomb structures is in the aerospace industry. Aircraft manufacturers leverage these materials to design components that require optimal load-bearing capacity coupled with minimal weight. For instance, components such as wings, flooring panels, and internal partitions extensively use aluminium honeycomb panels to enhance fuel efficiency and flight performance. The reduction in weight directly correlates to a reduction in fuel emissions, making them an eco-friendly choice aligned with global sustainability trends.

Moreover, cell aluminium honeycomb panels have made a significant mark in the automotive industry. With the constant demand for lightweight yet strong materials, these panels provide an impeccable solution for crafting energy-absorbing crumple zones, thus boosting vehicle safety standards. Incorporating these panels in the vehicle's framework also aids in enhancing the vehicle's overall performance by reducing weight and thereby improving fuel efficiency.

cell aluminium honeycomb

In the realm of architecture, cell aluminium honeycomb panels are increasingly favored for constructing facades, canopies, and interior partitions. Their resistance to environmental damage and wear makes them an ideal choice for enhancing building lifespan while reducing maintenance costs. Architects and designers appreciate the material's aesthetic pliability, which allows for creative and innovative architectural designs without compromising on structural integrity.

The marine industry, too, has tapped into the advantages of cell aluminium honeycomb structures. Ships and yachts utilize these materials in hulls and decking for their excellent strength and corrosion resistance — vital for withstanding harsh marine environments. The adoption of aluminium honeycomb panels in maritime construction not only bolsters safety but also contributes to prolonged vessel lifespan and reduced maintenance costs.

These pervasive applications underscore the authority of cell aluminium honeycomb structures in engineering solutions. Experts within the field are refining production techniques to enhance the availability and applicability of these materials, ensuring that they meet the evolving needs of modern industries. The trustworthiness of aluminium honeycomb panels is continually reinforced through rigorous testing, validating their performance in demanding environments.

To summarize, the innovative leverage provided by cell aluminium honeycomb structures continues to foster advancements across multiple sectors. Their exceptional blend of resilience and lightweight properties embodies the future of material engineering — pushing boundaries in industrial performance, sustainability, and design versatility. As industries increasingly turn towards sustainable and robust manufacturing solutions, cell aluminium honeycomb structures stand out as a testament to modern engineering’s progressive strides.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025