- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

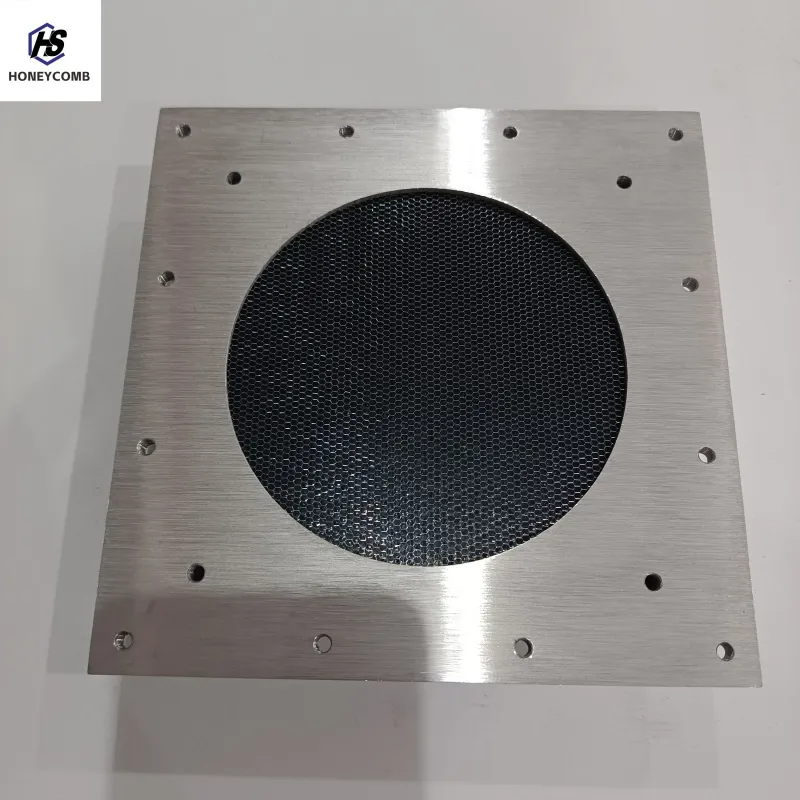

alloy honeycomb sheet

Alloy honeycomb sheets have become a pivotal component across multiple industries

, owing to their exceptional strength-to-weight ratio, versatility, and reliability. This article demystifies their composition, benefits, and applications, drawing insights from industry expertise and empirical experience to affirm their indispensable role in modern engineering and design.

Embracing innovation, alloy honeycomb sheets amalgamate various metals to achieve a balance of lightness and durability. Predominantly made from aluminum alloys, titanium, and sometimes even advanced composites, these sheets mimic the natural structure of honeycombs, optimized for load distribution and energy absorption. The selection of alloy is crucial—aluminum offers corrosion resistance and affordability, while titanium ensures superior strength with weight savings, ideal for aerospace requirements.

Decades of empirical data reveal that the unique geometry of honeycomb sheets allows them to endure substantial forces without deformation, contributing to enhanced safety and performance in critical applications. Their lightweight nature reduces the overall mass of structures, contributing to energy efficiency and cost savings in transportation sectors, including automotive and aviation industries. In architectural fields, they revolutionize façade and interior designs by providing creative freedom without compromising structural integrity.

With expertise rooted in years of research and real-world applications, it is evident that the manufacturing process is as vital as the materials themselves. Precision in cutting, bonding, and shaping these sheets determines the final product's efficiency. This is why industry leaders engage in continuous quality control, employing state-of-the-art technology and strict standards to ensure each sheet meets and exceeds project requirements.

alloy honeycomb sheet

The field of sustainability increasingly leans on alloy honeycomb sheets. Their potential for recyclability and energy conservation during transportation aligns with global green initiatives. They not only reduce carbon footprints by lowering energy consumption but are also produced using environmentally responsible methods, reinforcing their stature as an eco-friendly choice.

Industry authority consistently endorses alloy honeycomb sheets for their reliability in pioneering designs and projects. These materials are instrumental in projects ranging from cutting-edge aerospace fleets to innovative architectural marvels. Moreover, their usage extends to modern-day challenges, such as creating lightweight protection in personal armor and supporting renewable energy structures like wind turbines, showcasing their adaptability.

One cannot overlook the trustworthiness that alloy honeycomb sheets inspire among engineers, designers, and manufacturers. Their proven track record in enhancing safety and performance across various sectors underscores a level of trust that is unparalleled. Certifications from international standards bodies frequently accompany these products, adding layers of credibility and assurance of quality.

In conclusion, alloy honeycomb sheets embody the convergence of science and engineering, backed by extensive experience and expertise. Their remarkable attributes—versatility, strength, sustainability, and efficiency—render them a product of choice for industry leaders worldwide. As the demand for innovative solutions continues to rise, the role of alloy honeycomb sheets in meeting tomorrow's challenges is not just relevant, but essential.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025