- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 04, 2025 09:02

Back to list

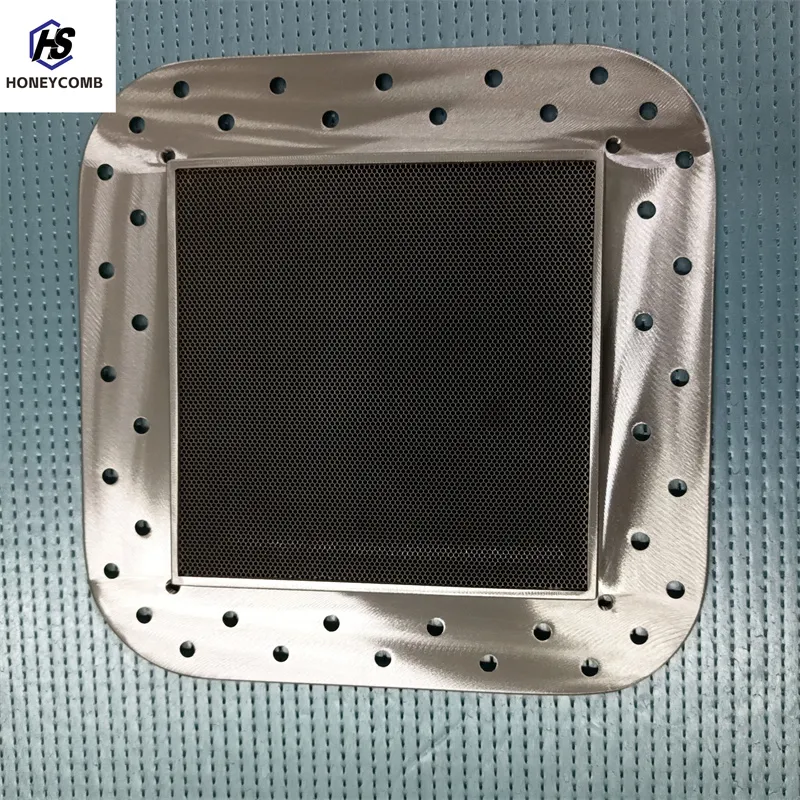

honeycomb in wind tunnel

Honeycomb structures have fascinated humans for centuries owing to their unique combination of strength, lightness, and utility. In today's world, the components of honeycomb structures have found applications in various industries, proving indispensable for manufacturers seeking to optimize materials for enhanced performance. At the essence of honeycomb components lies a meticulous design inspired by nature, showcasing the brilliance of combining geometry and material science.

In terms of expertise, mastering the production of honeycomb components demands a deep understanding of material properties and structural behavior. Engineers and material scientists continually experiment with honeycomb designs, exploring new configurations and materials to push the boundaries of what these components can achieve. This ongoing research and development ensure that honeycomb structures remain at the forefront of material innovation, providing cutting-edge solutions that evolve with technological advancements. The authoritative strength of honeycomb components is further evidenced by their regulatory acceptance and widespread industry application. Standards and certifications abound in sectors utilizing these structures, reflecting their crucial role in enhancing safety and efficiency. For producers, adhering to these guidelines not only establishes credibility but also fosters trust among consumers and industry partners. Finally, trustworthiness underpins the very nature of honeycomb components. The dependability of these materials in critical applications ensures that they are not just theoretical assets but practical solutions. Industries ranging from aerospace to logistics rely on the proven track record of honeycomb structures to achieve goals such as fuel efficiency, cost reduction, and noise attenuation. This trust is a testament to the rigorous testing and quality control that honeycomb components undergo before reaching the end-user. In conclusion, the components of honeycomb structures are more than mere materials; they are a synthesis of natural inspiration and scientific innovation, continually redefining the boundaries of what is possible in various industries. As companies seek to differentiate themselves in a competitive market, the judicious application of honeycomb technology will likely remain a critical factor in achieving superior performance and sustainability.

In terms of expertise, mastering the production of honeycomb components demands a deep understanding of material properties and structural behavior. Engineers and material scientists continually experiment with honeycomb designs, exploring new configurations and materials to push the boundaries of what these components can achieve. This ongoing research and development ensure that honeycomb structures remain at the forefront of material innovation, providing cutting-edge solutions that evolve with technological advancements. The authoritative strength of honeycomb components is further evidenced by their regulatory acceptance and widespread industry application. Standards and certifications abound in sectors utilizing these structures, reflecting their crucial role in enhancing safety and efficiency. For producers, adhering to these guidelines not only establishes credibility but also fosters trust among consumers and industry partners. Finally, trustworthiness underpins the very nature of honeycomb components. The dependability of these materials in critical applications ensures that they are not just theoretical assets but practical solutions. Industries ranging from aerospace to logistics rely on the proven track record of honeycomb structures to achieve goals such as fuel efficiency, cost reduction, and noise attenuation. This trust is a testament to the rigorous testing and quality control that honeycomb components undergo before reaching the end-user. In conclusion, the components of honeycomb structures are more than mere materials; they are a synthesis of natural inspiration and scientific innovation, continually redefining the boundaries of what is possible in various industries. As companies seek to differentiate themselves in a competitive market, the judicious application of honeycomb technology will likely remain a critical factor in achieving superior performance and sustainability.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025