- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 04, 2025 09:37

Back to list

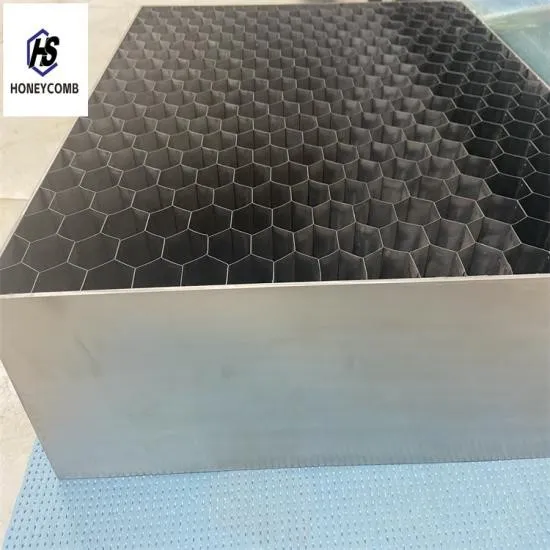

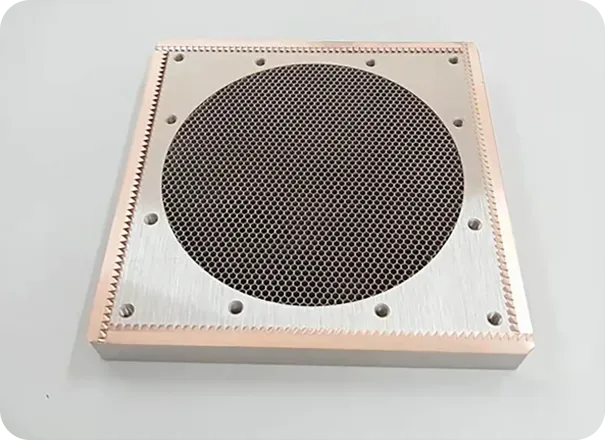

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

Flow rectifiers, often overshadowed by their more celebrated counterparts in the vast world of industrial equipment, play a crucial role in optimizing fluid dynamics across many sectors. These unobtrusive devices are pivotal in enhancing efficiency, reducing energy consumption, and prolonging the lifespan of more complex machinery.

Not merely functional, the design and material innovation in flow rectifiers enhance their capability to withstand extreme conditions, such as high pressure and temperature, further establishing their reliability. With advancements in materials science, modern flow rectifiers are now more compact, robust, and capable of operating under challenging conditions, a testament to their evolution from simple components to sophisticated instruments of engineering precision. Critically, the effectiveness of flow rectifiers does not solely rest on their physical attributes. Expertise in their implementation is equally vital. Engineers specializing in fluid dynamics possess the knowledge to customize and adjust flow rectifiers to fit a specific system or requirement. This level of customization ensures that companies derive maximum benefit, adhering to industrial best practices and optimizing their operational frameworks. For businesses contemplating the integration of flow rectifiers, selecting a manufacturer with a solid track record and a wealth of industry-specific knowledge cannot be overstated. Reputable manufacturers not only offer high-quality products but also provide invaluable consultation services, assisting companies in understanding precisely how integration can enhance their system’s efficiency. In conclusion, flow rectifiers are silent enablers of efficiency and precision across a myriad of industries. Their importance cannot be overstated, offering significant operational improvements, cost savings, and environmental benefits. As industries continue to push the boundaries of efficiency and precision, flow rectifiers will undoubtedly remain at the forefront, evolving alongside technological advancements to meet ever-increasing demands. Therefore, recognizing their value is imperative for any industry leader striving for excellence in fluid system management.

Not merely functional, the design and material innovation in flow rectifiers enhance their capability to withstand extreme conditions, such as high pressure and temperature, further establishing their reliability. With advancements in materials science, modern flow rectifiers are now more compact, robust, and capable of operating under challenging conditions, a testament to their evolution from simple components to sophisticated instruments of engineering precision. Critically, the effectiveness of flow rectifiers does not solely rest on their physical attributes. Expertise in their implementation is equally vital. Engineers specializing in fluid dynamics possess the knowledge to customize and adjust flow rectifiers to fit a specific system or requirement. This level of customization ensures that companies derive maximum benefit, adhering to industrial best practices and optimizing their operational frameworks. For businesses contemplating the integration of flow rectifiers, selecting a manufacturer with a solid track record and a wealth of industry-specific knowledge cannot be overstated. Reputable manufacturers not only offer high-quality products but also provide invaluable consultation services, assisting companies in understanding precisely how integration can enhance their system’s efficiency. In conclusion, flow rectifiers are silent enablers of efficiency and precision across a myriad of industries. Their importance cannot be overstated, offering significant operational improvements, cost savings, and environmental benefits. As industries continue to push the boundaries of efficiency and precision, flow rectifiers will undoubtedly remain at the forefront, evolving alongside technological advancements to meet ever-increasing demands. Therefore, recognizing their value is imperative for any industry leader striving for excellence in fluid system management.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025