- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 13:38

Back to list

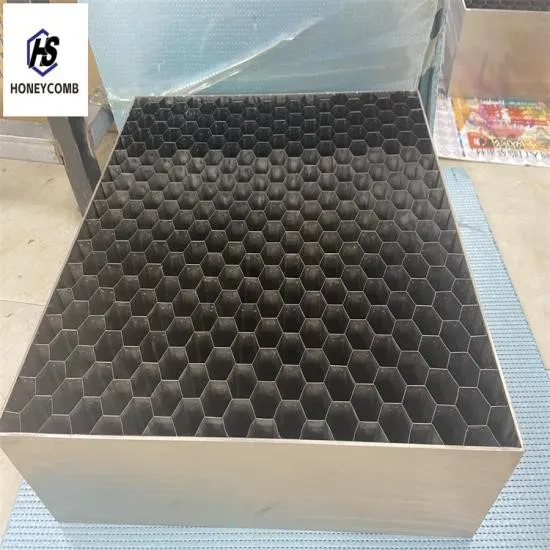

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent

The versatility and efficiency of honeycomb components are increasingly recognized in various industries, marking them as a pivotal innovation in product design and engineering. Harnessing the inherent structural advantages of a honeycomb pattern, these components are revolutionizing sectors ranging from aerospace to automotive manufacturing, with a profound impact on both performance and sustainability metrics.

Honeycomb components are not limited to heavy industries; they are equally impactful in everyday consumer products. In the sports equipment sector, for example, the integration of honeycomb materials into the design of bicycles, helmets, and even surfboards showcases their multifaceted utility. These products benefit from the same essential qualities reduced weight, enhanced strength, and improved safety, aligning with consumer demands for durable and high-performance sporting goods. The use of honeycomb structures in these applications reflects expert craftsmanship guided by rigorous testing and development processes, ensuring that each product is both revolutionary and trustworthy. Incorporating honeycomb components across diverse fields calls for knowledgeable and skilled professionals who understand their full potential and applications. The deployment of these components is driven by engineers, product designers, and industry experts who continually explore new possibilities and push the limits of what is achievable. This dedication is crucial for maintaining the authority and credibility of honeycomb components as pivotal solutions to modern engineering challenges. Thus, the growing adoption of honeycomb components is not just a fleeting trend but a testament to their undeniable advantages and reliability in product innovation. As industries continue to evolve and prioritize sustainability and efficiency, it is clear that honeycomb components will remain at the forefront of this progression. With every successful application, they bolster our confidence in their capability and enhance the trust placed in them by industries and consumers alike. This ongoing evolution underscores the need for continued investment in research and development, ensuring honeycomb technology remains on the cutting edge of modern science and engineering.

Honeycomb components are not limited to heavy industries; they are equally impactful in everyday consumer products. In the sports equipment sector, for example, the integration of honeycomb materials into the design of bicycles, helmets, and even surfboards showcases their multifaceted utility. These products benefit from the same essential qualities reduced weight, enhanced strength, and improved safety, aligning with consumer demands for durable and high-performance sporting goods. The use of honeycomb structures in these applications reflects expert craftsmanship guided by rigorous testing and development processes, ensuring that each product is both revolutionary and trustworthy. Incorporating honeycomb components across diverse fields calls for knowledgeable and skilled professionals who understand their full potential and applications. The deployment of these components is driven by engineers, product designers, and industry experts who continually explore new possibilities and push the limits of what is achievable. This dedication is crucial for maintaining the authority and credibility of honeycomb components as pivotal solutions to modern engineering challenges. Thus, the growing adoption of honeycomb components is not just a fleeting trend but a testament to their undeniable advantages and reliability in product innovation. As industries continue to evolve and prioritize sustainability and efficiency, it is clear that honeycomb components will remain at the forefront of this progression. With every successful application, they bolster our confidence in their capability and enhance the trust placed in them by industries and consumers alike. This ongoing evolution underscores the need for continued investment in research and development, ensuring honeycomb technology remains on the cutting edge of modern science and engineering.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025