- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 14:05

Back to list

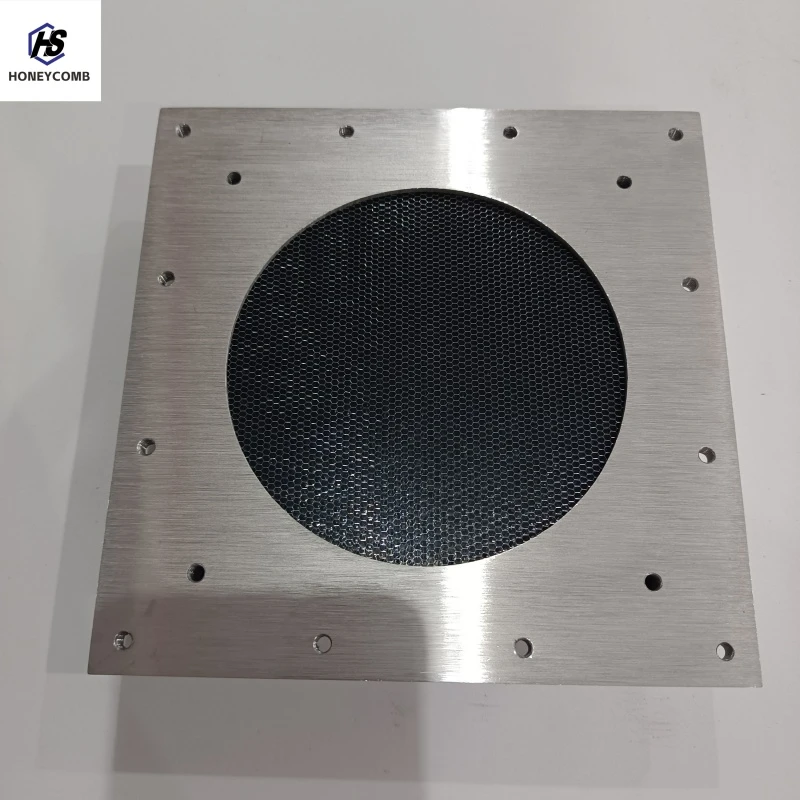

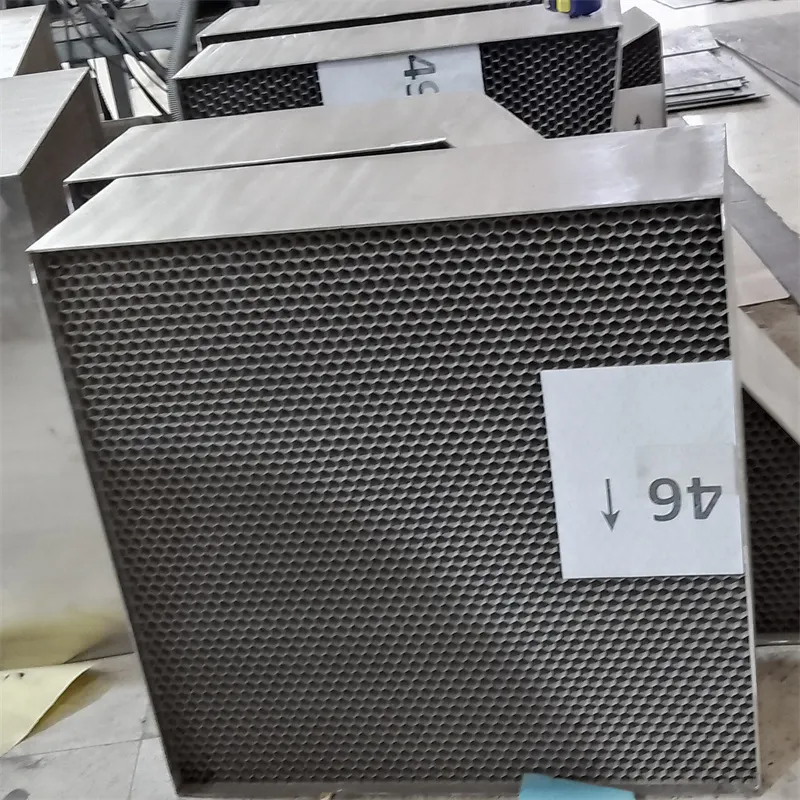

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

The Rectifier of Flow, or raddrizzatore di flusso in Italian, stands as a pinnacle of engineering innovation, catering to the demand for efficient energy conversion and management. This device, crucial in numerous industries, transforms alternating current (AC) into direct current (DC), proving indispensable in a world increasingly reliant on precise electronic applications.

In terms of expertise, manufacturers of flow rectifiers dedicate extensive research and development to refine these devices. Advanced models now include sophisticated features like thermal protection, real-time monitoring, and adaptive efficiency controls. This technological sophistication matches the dynamic needs of modern industries where energy management protocols are constantly evolving to adapt to newer standards of sustainability and performance. Engineers and technicians often highlight the modularity of modern flow rectifiers, which allows for integration into existing systems without necessitating major overhauls. This adaptability not only underscores the expert engineering behind these devices but also aligns with the pragmatic needs of industry professionals seeking upgrades without excessive downtime or costs. Finally, trust in flow rectifiers as a cornerstone of energy management is bolstered by a track record of reliable performance. Manufacturers provide warranties and customer support, ensuring that any issues encountered in practical applications are swiftly resolved. Such measures are pivotal in establishing customer confidence, as users can depend on manufacturer expertise and resources. In essence, the rectifier of flow serves as a conduit for both energy and technological advancement. Its continued innovation drives industries forward, enhancing efficiency, and safety, and promising a future where energy systems are not only sustainable but also robust and adaptable to the ever-evolving landscape of electronic demands. With each iteration, these devices reflect a deeper understanding and mastery of energy management, cementing their place as indispensable tools in our increasingly electrified world.

In terms of expertise, manufacturers of flow rectifiers dedicate extensive research and development to refine these devices. Advanced models now include sophisticated features like thermal protection, real-time monitoring, and adaptive efficiency controls. This technological sophistication matches the dynamic needs of modern industries where energy management protocols are constantly evolving to adapt to newer standards of sustainability and performance. Engineers and technicians often highlight the modularity of modern flow rectifiers, which allows for integration into existing systems without necessitating major overhauls. This adaptability not only underscores the expert engineering behind these devices but also aligns with the pragmatic needs of industry professionals seeking upgrades without excessive downtime or costs. Finally, trust in flow rectifiers as a cornerstone of energy management is bolstered by a track record of reliable performance. Manufacturers provide warranties and customer support, ensuring that any issues encountered in practical applications are swiftly resolved. Such measures are pivotal in establishing customer confidence, as users can depend on manufacturer expertise and resources. In essence, the rectifier of flow serves as a conduit for both energy and technological advancement. Its continued innovation drives industries forward, enhancing efficiency, and safety, and promising a future where energy systems are not only sustainable but also robust and adaptable to the ever-evolving landscape of electronic demands. With each iteration, these devices reflect a deeper understanding and mastery of energy management, cementing their place as indispensable tools in our increasingly electrified world.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025