- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 21, 2025 01:00

Back to list

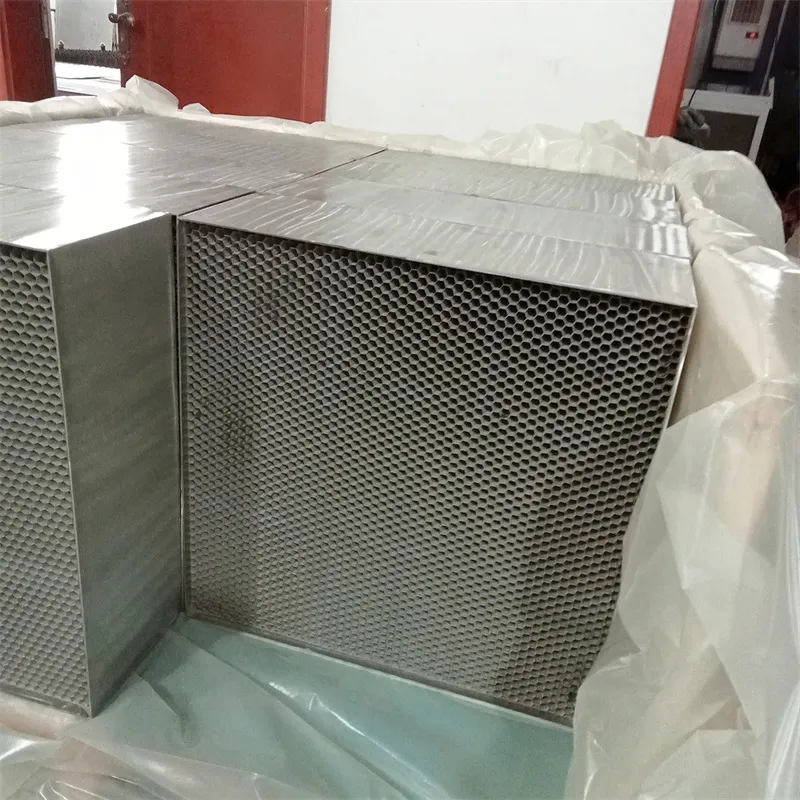

cruach dhosmálta honeycomb

The stainless steel honeycomb is a distinctive product that has been transforming industries with its exceptional properties and versatile applications. Known for its strength, durability, and lightweight nature, stainless steel honeycomb structures are increasingly being utilized in sectors such as aerospace, automotive, architecture, and marine engineering. This innovative material offers a fascinating blend of design flexibility and robustness that is simply unmatched by traditional materials.

Experience in utilizing stainless steel honeycomb across various sectors reveals that this material provides unparalleled benefits in terms of lifecycle cost. While the initial investment may be higher compared to conventional materials, the longevity and performance gains significantly outweigh the early expenses. This is echoed by numerous industry experts who advocate its adoption, emphasizing the cost-efficiency and enhanced performance that stainless steel honeycomb delivers over its lifetime. Moreover, from a sustainability perspective, stainless steel honeycomb is a frontrunner. Its recyclability and the minimal raw materials required for its production align well with the global push towards greener engineering solutions. Products made from stainless steel honeycomb can be repurposed without losing integrity, reducing waste and conserving resources. The energy efficiency benefits during the manufacturing process further bolster its eco-friendly credentials, making it an excellent choice for companies striving to reduce their carbon footprint. Ultimately, the trustworthiness of stainless steel honeycomb as a material choice is backed by decades of proven performance and continuous advancements in manufacturing technologies. Industry leaders and experts consistently endorse its use, providing a solid testament to its reliability and efficacy. As research and development in this field progress, the potential for new applications and enhancements in material properties will undoubtedly broaden, paving the way for even greater innovations across various domains. For professionals seeking a reliable and efficient material that meets the demands of modern engineering, stainless steel honeycomb stands out as a remarkable option. Its unique combination of strength, resistance, and lightweight properties ensures that it is not just a choice of material, but a strategic decision towards future-ready engineering solutions. Whether in constructing the next generation of aircraft, designing eco-friendly vehicles, or building sustainable architectural masterpieces, stainless steel honeycomb continues to set benchmarks for performance and reliability.

Experience in utilizing stainless steel honeycomb across various sectors reveals that this material provides unparalleled benefits in terms of lifecycle cost. While the initial investment may be higher compared to conventional materials, the longevity and performance gains significantly outweigh the early expenses. This is echoed by numerous industry experts who advocate its adoption, emphasizing the cost-efficiency and enhanced performance that stainless steel honeycomb delivers over its lifetime. Moreover, from a sustainability perspective, stainless steel honeycomb is a frontrunner. Its recyclability and the minimal raw materials required for its production align well with the global push towards greener engineering solutions. Products made from stainless steel honeycomb can be repurposed without losing integrity, reducing waste and conserving resources. The energy efficiency benefits during the manufacturing process further bolster its eco-friendly credentials, making it an excellent choice for companies striving to reduce their carbon footprint. Ultimately, the trustworthiness of stainless steel honeycomb as a material choice is backed by decades of proven performance and continuous advancements in manufacturing technologies. Industry leaders and experts consistently endorse its use, providing a solid testament to its reliability and efficacy. As research and development in this field progress, the potential for new applications and enhancements in material properties will undoubtedly broaden, paving the way for even greater innovations across various domains. For professionals seeking a reliable and efficient material that meets the demands of modern engineering, stainless steel honeycomb stands out as a remarkable option. Its unique combination of strength, resistance, and lightweight properties ensures that it is not just a choice of material, but a strategic decision towards future-ready engineering solutions. Whether in constructing the next generation of aircraft, designing eco-friendly vehicles, or building sustainable architectural masterpieces, stainless steel honeycomb continues to set benchmarks for performance and reliability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025