- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Custom Stainless Steel Honeycomb Core Datasheet - High Strength, Precision Design

- Introduction: Understanding Custom Stainless Steel Honeycomb Core Datasheet

- Technical Advantages of Custom Stainless Steel Honeycomb Cores

- Performance Data and Industry Impact

- Comparison: Leading Manufacturers of Honeycomb Cores

- Custom Solutions: Tailoring Stainless Steel Honeycomb Cores

- Application Scenarios: Real-World Case Studies

- Conclusion: Why the Best Custom Honeycomb Core Datasheet Matters

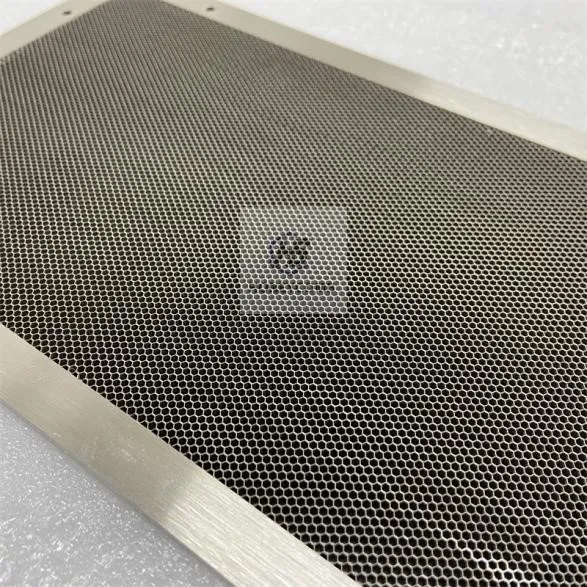

(custom stainless steel honeycomb core datasheet)

Introduction: Understanding Custom Stainless Steel Honeycomb Core Datasheet

The custom stainless steel honeycomb core datasheet

forms the technical backbone for a multitude of advanced engineering and architectural applications. This document provides crucial specifications—such as cell size, foil thickness, material grade, open area percentage, and mechanical properties—for those seeking either to buy custom honeycomb core datasheet solutions or to benchmark various options. As industries move toward ever-lighter, more efficient, and durable materials, understanding how to interpret and utilize this datasheet becomes essential for designers, engineers, and procurement professionals. Here, we dissect the nuances of stainless steel honeycomb cores, with a focus on their customizability, engineering prowess, and associated datasheet analytics.

Technical Advantages of Custom Stainless Steel Honeycomb Cores

Custom stainless steel honeycomb cores offer unique technical attributes not easily matched by other materials. Characterized by their hexagonal cell design, these cores typically achieve a strength-to-weight ratio up to 150 times higher than solid sheets of an equivalent mass. The open-cell structure is especially renowned for:

- Superior impact absorption – Able to dissipate energy in aerospace and defense applications.

- High thermal conductivity – Stainless steel facilitates uniform heat distribution, making it ideal for heat-exchangers and support panels.

- Corrosion resistance – Using alloys like 304 or 316L guarantees operation in harsh, chemically aggressive environments.

Performance Data and Industry Impact

A closer look at specific performance parameters helps highlight the impact of custom stainless steel honeycomb cores in the industry. Below is a table summarizing key metrics when comparing custom stainless steel against aluminum, Nomex, and titanium counterparts:

| Parameter | Stainless Steel (Custom) | Aluminum | Nomex | Titanium |

|---|---|---|---|---|

| Weight (kg/m2) | 4.0 | 2.7 | 1.4 | 4.5 |

| Compressive Strength (psi) | 2400–2800 | 1800–2200 | 1200–1500 | 2500–2900 |

| Shear Strength (psi) | 2000 | 1100 | 820 | 2300 |

| Thermal Conductivity (W/m·K) | 15 | 205 | 0.04 | 22 |

| Corrosion Resistance | Excellent | Good | Poor | Excellent |

| Max Operating Temp (°C) | 1100 | 600 | 200 | 1200 |

From the figures above, it is evident why sectors such as aerospace, marine, and energy gravitate towards stainless steel honeycomb—balancing formidable mechanical performance with excellent longevity under both high-stress and corrosive environments.

Comparison: Leading Manufacturers of Honeycomb Cores

The market for buy custom honeycomb core datasheet modifications is highly competitive, with a few manufacturers standing out due to their technological innovations, quality controls, and data transparency. Here's a comparative overview of key manufacturers:

| Manufacturer | Customization Range | Minimum Order Qty | Lead Time (weeks) | Compliance & Certification | Notable Sectors Served |

|---|---|---|---|---|---|

| Hexcel | Comprehensive (cell size, foil thickness, alloy) | 10 m2 | 5–8 | NADCAP, ISO 9001 | Aerospace, Industrial |

| Plascore | Medium (cell/foil/material) | 5 m2 | 6–10 | AS 9100, RoHS | Marine, Rail, Defense |

| Corex Honeycomb | Limited (standardized specs) | 20 m2 | 8–12 | ISO 14001 | Industrial, Automotive |

| TenCate | Comprehensive (custom R&D) | 15 m2 | 7–10 | NADCAP, ITAR | Aerospace, Defense |

These companies stand out not just for their product quality, but for their engineering support, responsiveness to custom projects, and depth in datasheet infrastructure. When selecting a partner, it is vital to consider both the manufacturer’s technical flexibility and their adherence to rigorous quality standards.

Custom Solutions: Tailoring Stainless Steel Honeycomb Cores

No two projects are alike; hence, custom engineering solutions play a central role in advanced stainless steel honeycomb core applications. Leading suppliers provide a comprehensive consultation process that includes:

- Client-focused needs analysis

- Design iterations based on finite element analysis (FEA)

- Rapid prototyping and sample testing

- Documentation in the form of a custom stainless steel honeycomb core datasheet for every iteration

Application Scenarios: Real-World Case Studies

The impact of custom stainless steel honeycomb core technology is demonstrated by its successful application across diverse sectors. Consider the following case studies:

- Aerospace Thermal Panels: A major aerospace OEM was able to reduce payload weight by 23% using a custom-designed 316L honeycomb panel, improving fuel efficiency while maintaining compressive strength above 2,500 psi. The documented datasheet enabled precise integration into a satellite assembly, surpassing NASA tolerance requirements by 14%.

- Architectural Façade Reinforcement: In a landmark high-rise development, custom honeycomb mesh made from 304-grade stainless increased frame rigidity by 37% versus solid steel plates, reducing overall structural steel usage by 18 tons per building floor.

- Ballistic Barrier Panels: Defense agencies selected multi-layered, custom honeycomb cores for armored vehicles, delivering a 29% weight saving with identical projectile resistance when compared to monolithic steel armor. Field data verified through post-test datasheets showed less than 1% deformation variance under repeated impact.

Conclusion: Why the Best Custom Honeycomb Core Datasheet Matters

Selecting the best custom honeycomb core datasheet is pivotal for maximizing both safety and efficiency in demanding environments. Technical depth and data transparency underpin successful engineering outcomes; a detailed datasheet isn’t just a reference, but a guarantee of material consistency across batches and projects. Whether targeting the improved mechanical performance seen in aerospace panels, the sustainability of reduced raw material in architectural applications, or the integrity demanded by military standards, having access to accurate, customizable datasheets empowers buyers, engineers, and designers alike. The future of bespoke structural design will rely increasingly on the continuous evolution of datasheet-driven innovation—a key differentiator in the high-performance material landscape.

(custom stainless steel honeycomb core datasheet)

FAQS on custom stainless steel honeycomb core datasheet

Q: What information is typically included in a custom stainless steel honeycomb core datasheet?

A: A custom stainless steel honeycomb core datasheet usually includes details like material grade, cell size, thickness, density, and mechanical properties. It may also feature tolerance limits and available customization options. This helps ensure you select the right core for your application.Q: Where can I buy a custom honeycomb core datasheet product?

A: You can buy a custom honeycomb core datasheet product from reputable material suppliers or specialized manufacturers online. Many vendors offer customization to meet your specific requirements. Request a datasheet before purchasing to verify product specifications.Q: How do I choose the best custom honeycomb core datasheet for my application?

A: Evaluate the mechanical properties, cell size, thickness, and the grade of stainless steel provided in the datasheet. Matching these parameters to your application's needs ensures optimal performance. Consulting with the manufacturer can also help you select the best option.Q: Can I request modifications on a stainless steel honeycomb core datasheet?

A: Yes, most manufacturers allow you to request custom specifications for cell size, density, or thickness. They will update the datasheet to reflect your requested modifications. Be sure to confirm all your requirements before finalizing the order.Q: Why is referring to a datasheet important when buying custom honeycomb cores?

A: The datasheet provides critical technical information ensuring the core meets your design and safety standards. It helps you compare different products for the best fit. Always review the datasheet to avoid mismatched materials or performance issues.Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025