- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

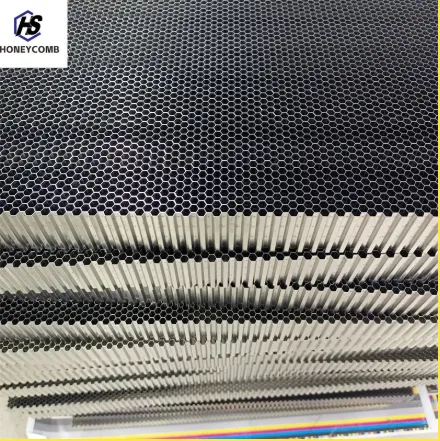

High-Quality Honeycomb Core Material for Design & Military Use Reliable Supplier

- Introduction: honeycomb core material

technologies and relevance - Technical advantages and structural properties of honeycomb core materials

- Market comparison: analyzing leading military grade honeycomb core material suppliers

- Custom design solutions when you buy honeycomb core material

- Application showcases: aerospace, construction, and marine industries

- Challenges, recent innovations, and future trends

- Conclusion: Investing in advanced honeycomb core material for sustainable engineering

(honeycomb core material)

Unlocking the Potential of Honeycomb Core Material in Engineering

The evolution of honeycomb core material has been transformative in the fields of aerospace, automotive, marine, defense, and construction. Characterized by a unique cellular geometry, this lightweight yet high-strength material has set benchmarks for load-bearing performance and versatility. Global demand for honeycomb cores is expected to rise annually by 7.2% through 2030, hitting an estimated market size of $4.3 billion, according to MarketsandMarkets research. This growth is driven by a global push for lightweight structures that can withstand significant stress without added mass. With the emerging trend of sustainable engineering, professionals seeking to buy honeycomb core material design are increasingly focusing on recyclable compositions and low-VOC manufacturing methods. The intricate geometry of these products not only offers phenomenal mechanical properties but also introduces significant thermal, acoustic, and fire-resistant benefits.

Technical Advantages and Structural Properties

At the heart of honeycomb core technology is its geometric arrangement; each cell distributes load across a broad area, lowering the weight-to-strength ratio to as little as 30 kg/m³ with compressive strengths exceeding 1 MPa for advanced military applications. The material is commonly fabricated from metals like aluminium, aramid fiber (Nomex®), paper, or advanced thermoplastic polymers, offering a wide material spectrum to match specific environmental needs and load criteria. Key technical metrics include:

- Superior stiffness-to-weight ratios: up to 150 times stiffer than uniform foams

- Excellent energy absorption, enhancing crashworthiness and impact resistance

- Thermal conductivity values below 0.03 W/mK in certain polymeric cores, optimizing insulation

- Remarkable fatigue life, outlasting traditional balsa or solid composites by 40–60% under cyclic loads

- High customizability—cell size and density directly influence compressive and shear performance

Supplier Performance: Military Grade Honeycomb Core Material Comparison

Selecting the ideal military grade honeycomb core material supplier is a decisive factor for mission-critical applications where failure is not an option. Below is a comprehensive comparison of leading global suppliers, based on technical data, quality certifications, and delivery capabilities.

| Supplier | Core Material Type | Compressive Strength (MPa) | Density (kg/m3) | Certifications | Minimum Lead Time (weeks) |

|---|---|---|---|---|---|

| Hexcel Corporation | Aluminum, Nomex® | 2.1–5.5 | 32–80 | AS9100, ISO 9001 | 4 |

| Euro-Composites S.A. | Aramid, Paper, Aluminum | 1.5–4.7 | 29–65 | NADCAP, EN9100 | 5 |

| Plascore Inc. | Aluminum, Thermoplastics | 0.8–2.9 | 30–74 | ISO 9001, ITAR | 3 |

| Cellbond | Aluminum | 2.0–4.5 | 35–60 | ISO 9001 | 6 |

The table underscores notable differences in compressive strength, material selection, and logistics. Notably, Hexcel stands out with its extensive range and industry-leading certifications, while Plascore ships with the shortest lead time, and Euro-Composites offers one of the broadest material choices ideal for niche defense applications.

Custom Design: Tailored Honeycomb Core Material for Specific Applications

The ability to buy honeycomb core material design tailored to a project's unique demands is pivotal for industries where precision and optimization are non-negotiable. Customizable parameters include:

- Cell geometry (hexagonal, over-expanded, reinforced)

- Core thickness (2 mm up to 300 mm)

- Material selection based on temperature resistance, conductivity, or chemical inertness

- Surface treatments for corrosion or fire retardancy

- Localized reinforcement zones for mounting or fastener points

Application Showcases: Multi-Sector Impact of Honeycomb Core Technologies

The diverse utility of honeycomb core material transcends industry boundaries. In aerospace, sandwich panels with 1/32-inch cell aluminum cores are specified for bulkheads, floors, and control surfaces, reducing aircraft mass by up to 1,000 kg—translating to fuel savings of 160,000 liters over a commercial jet's 15-year operational lifespan.

In construction, modular wall panels with high-density paper-based honeycomb lower structural costs by 12% and permit rapid installation, outperforming conventional masonry for non-load-bearing applications. For marine craft, aramid honeycomb structures are employed for high-performance hulls, with 40% better impact absorption versus foam cores, significantly boosting safety and survivability.

Case study: By integrating honeycomb cores into their mass transit trains, a major EU railway provider improved energy efficiency per carriage by 8.6%, meeting rigorous environmental targets and reducing annual CO2 emissions by 1,150 tons. These application scenarios are underpinned by strict compliance testing per ASTM C365 and EN14509 standards, guaranteeing fitness for real-world deployment.

Market Challenges, Innovations, and Future Trends

Despite its broad adoption, the honeycomb core market faces ongoing challenges, including price volatility in raw aluminum and advanced fibers, as well as increasingly complex environmental regulations. Suppliers have responded by developing new material formulations—such as recyclable thermoplastic cores and bio-based resins—balancing sustainability imperatives with technical rigor. Additive manufacturing is also emerging as a disruptor; 3D printing enables intricate core structures previously unachievable with traditional extrusion or expansion methods, reducing material scrap by up to 25%.

Future trajectories point toward artificial intelligence-assisted design (generative design) for core optimization and enhanced in-line quality control using non-destructive imaging. Analysts forecast a surge in demand from electric vehicle and modular housing sectors, with electric mobility alone expected to require over 90,000 m3 of honeycomb core material annually by 2028. These shifts will redefine material hierarchies and accelerate cross-sector knowledge transfer.

Conclusion: The Strategic Value of Honeycomb Core Material for Next-Generation Engineering

Advancements in honeycomb core material technology are driving new engineering frontiers, from ultra-lightweight aerospace assemblies to resilient, eco-friendly construction and defense systems. Organizations that align with the best military grade honeycomb core material supplier and capitalize on tailored design solutions stand to gain a critical competitive edge—achieving higher performance, cost efficiencies, and reduced environmental impact. As regulation tightens and market requirements evolve, the ability to innovate within the honeycomb core ecosystem will remain a key differentiator. The future belongs to those who not only adapt to foundational materials but shape them to deliver on the promise of sustainable, high-strength, and versatile engineering.

(honeycomb core material)

FAQS on honeycomb core material

Q: What is honeycomb core material?

A: Honeycomb core material is a lightweight structural material with a hexagonal cell structure. It’s widely used in aerospace, automotive, and construction industries for its high strength-to-weight ratio. Its design mimics natural honeycomb for optimal support.Q: Where can I buy honeycomb core material for my design project?

A: You can purchase honeycomb core material from specialized industrial suppliers or online platforms. Be sure to consider the material type and specifications required for your design needs. Some suppliers offer customization for specific projects.Q: What are the advantages of military grade honeycomb core material?

A: Military grade honeycomb core material offers superior strength, durability, and resistance to harsh environments. It also meets rigorous quality and safety standards. Such core materials are ideal for defense and aerospace applications.Q: How do I choose the right honeycomb core material supplier?

A: Look for suppliers with proven experience in your industry, quality certifications, and customization options. Consider their ability to supply military grade and other specialized honeycomb products. Customer reviews and technical support are also important.Q: Can honeycomb core material be customized for unique design requirements?

A: Yes, many suppliers offer customization in cell size, material, and thickness. Custom honeycomb cores can be tailored for specific structural and weight needs. Contact your chosen supplier to discuss technical possibilities.Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025