- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 08:12

Back to list

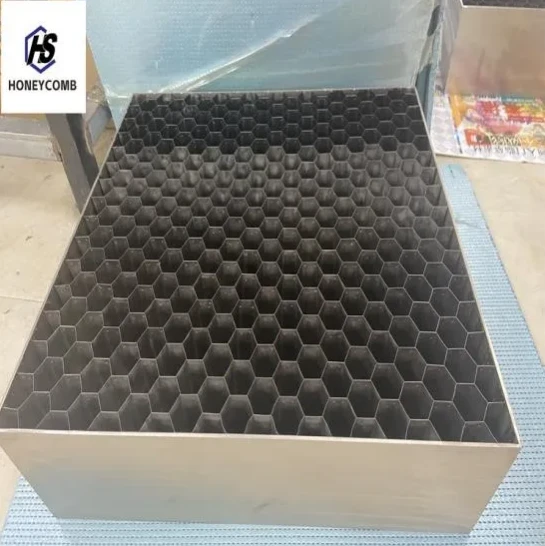

emi honeycomb

Electromagnetic interference (EMI) has become a significant concern in today's technology-driven world, with the increasing density of electronic devices. EMI can cause devices to malfunction or underperform, leading to costly repairs and operational inefficiencies. One practical solution to mitigate EMI issues is through the use of EMI-shielded vents and filters. These components provide essential protection, ensuring devices operate smoothly and safely.

Real-world experience underscores the effectiveness of EMI protection strategies. For instance, in the telecommunications industry, maintaining signal integrity is paramount. Achieving this often involves strategically placing EMI-shielded vents and filters in base stations to protect sensitive antennas and signal processors from external interference. Similarly, in the medical field, ensuring accurate readings from diagnostic equipment, like MRI machines, requires effective EMI reduction to prevent deviations caused by external sources. When choosing EMI-shielded vents and filters, trustworthiness is vital. Reputable manufacturers provide comprehensive testing data and certifications to verify their products' efficacy. Potential buyers should seek out these credentials, as well as customer testimonials and case studies, to ensure they are making informed decisions. A product backed by proven results and positive user experiences is far more likely to deliver on its promises. It's also essential to maintain flexibility and adaptability in product designs, as new technologies and standards emerge. Custom solutions tailored to specific applications can provide optimal performance, and partnering with experienced manufacturers for bespoke designs can lead to superior outcomes. As technology continues to evolve, the need for advanced EMI protection solutions will only grow, placing a premium on products that combine functionality, innovation, and compliance. In conclusion, EMI-shielded vents and filters play a crucial role in modern electronic design, ensuring devices operate without interference. With expertise, authoritativeness, and trustworthiness as guiding principles, these components contribute significantly to the reliability and effectiveness of electronic systems. Whether in industrial, medical, or consumer electronics, investing in high-quality EMI-shielded products is a strategic move that safeguards performance and fosters technological advancement.

Real-world experience underscores the effectiveness of EMI protection strategies. For instance, in the telecommunications industry, maintaining signal integrity is paramount. Achieving this often involves strategically placing EMI-shielded vents and filters in base stations to protect sensitive antennas and signal processors from external interference. Similarly, in the medical field, ensuring accurate readings from diagnostic equipment, like MRI machines, requires effective EMI reduction to prevent deviations caused by external sources. When choosing EMI-shielded vents and filters, trustworthiness is vital. Reputable manufacturers provide comprehensive testing data and certifications to verify their products' efficacy. Potential buyers should seek out these credentials, as well as customer testimonials and case studies, to ensure they are making informed decisions. A product backed by proven results and positive user experiences is far more likely to deliver on its promises. It's also essential to maintain flexibility and adaptability in product designs, as new technologies and standards emerge. Custom solutions tailored to specific applications can provide optimal performance, and partnering with experienced manufacturers for bespoke designs can lead to superior outcomes. As technology continues to evolve, the need for advanced EMI protection solutions will only grow, placing a premium on products that combine functionality, innovation, and compliance. In conclusion, EMI-shielded vents and filters play a crucial role in modern electronic design, ensuring devices operate without interference. With expertise, authoritativeness, and trustworthiness as guiding principles, these components contribute significantly to the reliability and effectiveness of electronic systems. Whether in industrial, medical, or consumer electronics, investing in high-quality EMI-shielded products is a strategic move that safeguards performance and fosters technological advancement.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025