- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 08:34

Back to list

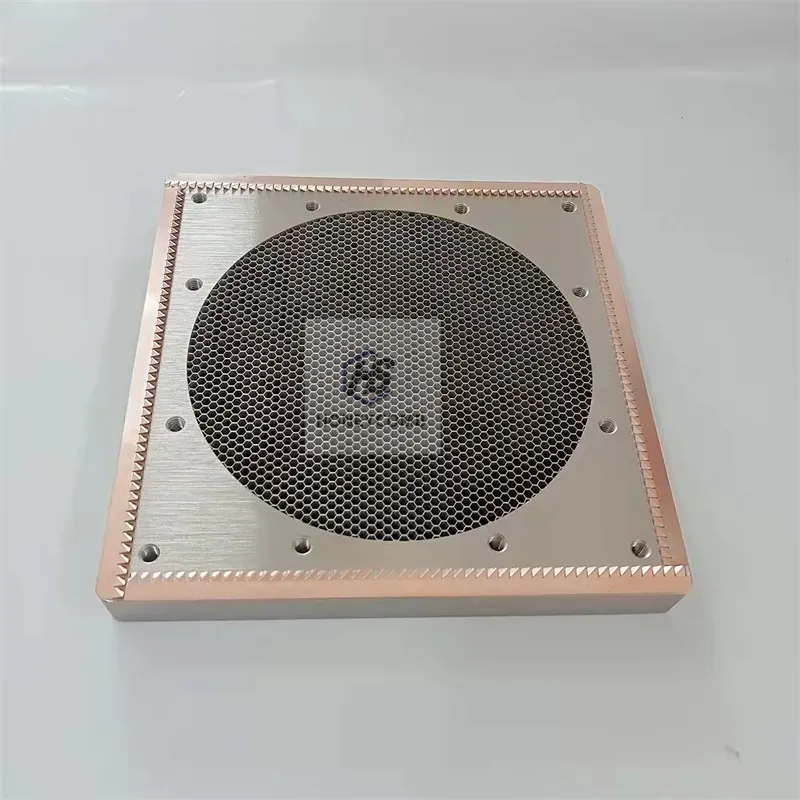

20mm Core Size Stainless Steel Honeycomb Core Panel - Customized for Wind Tunnel Applications

Kupferwaben, as a revolutionary product, has been quietly transforming sectors where durability and efficiency are paramount. This cutting-edge innovation, directly translating to copper honeycombs in English, promises to redefine how we think about material performance and sustainability.

Trust in Kupferwaben is further solidified through certifications from international quality standard bodies. Products utilizing Kupferwaben have consistently met ISO and ASTM standards due to their reliable performance and safety aspects. Additionally, companies that have integrated Kupferwaben into their product lines have reported substantial improvements in product lifecycle and customer satisfaction, emphasizing the credible and trustworthy nature of this material. In the competitive sphere of renewable energy, Kupferwaben’s properties are particularly groundbreaking. Solar panels, outfitted with this technology, benefit from improved efficiency due to superior heat dissipation. This leads to better performance under high-temperature conditions — a significant advantage in maximizing energy capture and conversion rates. Beyond performance metrics, the sustainability aspect of Kupferwaben marks a leap forward in eco-friendly design. The recyclable nature of copper ensures that the environmental footprint of products integrating Kupferwaben is minimized. This aligns with global efforts towards sustainable industrial practices and highlights the forward-thinking approach of this technology. In conclusion, Kupferwaben represents not just a new product, but a shift towards advanced materials that embody reliability, efficiency, and sustainability. By prioritizing these attributes, industries not only enhance their operational capabilities but also contribute positively to global ecological standards. As businesses continue to explore innovative materials, the integration of Kupferwaben presents an unmissable opportunity to advance both technologically and responsibly.

Trust in Kupferwaben is further solidified through certifications from international quality standard bodies. Products utilizing Kupferwaben have consistently met ISO and ASTM standards due to their reliable performance and safety aspects. Additionally, companies that have integrated Kupferwaben into their product lines have reported substantial improvements in product lifecycle and customer satisfaction, emphasizing the credible and trustworthy nature of this material. In the competitive sphere of renewable energy, Kupferwaben’s properties are particularly groundbreaking. Solar panels, outfitted with this technology, benefit from improved efficiency due to superior heat dissipation. This leads to better performance under high-temperature conditions — a significant advantage in maximizing energy capture and conversion rates. Beyond performance metrics, the sustainability aspect of Kupferwaben marks a leap forward in eco-friendly design. The recyclable nature of copper ensures that the environmental footprint of products integrating Kupferwaben is minimized. This aligns with global efforts towards sustainable industrial practices and highlights the forward-thinking approach of this technology. In conclusion, Kupferwaben represents not just a new product, but a shift towards advanced materials that embody reliability, efficiency, and sustainability. By prioritizing these attributes, industries not only enhance their operational capabilities but also contribute positively to global ecological standards. As businesses continue to explore innovative materials, the integration of Kupferwaben presents an unmissable opportunity to advance both technologically and responsibly.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025