- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 10:13

Back to list

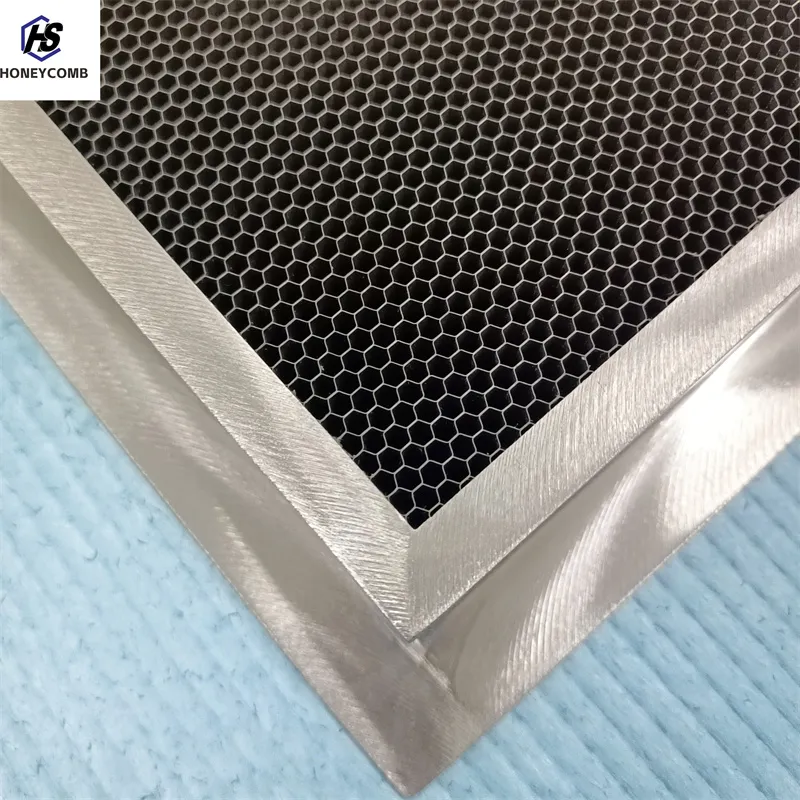

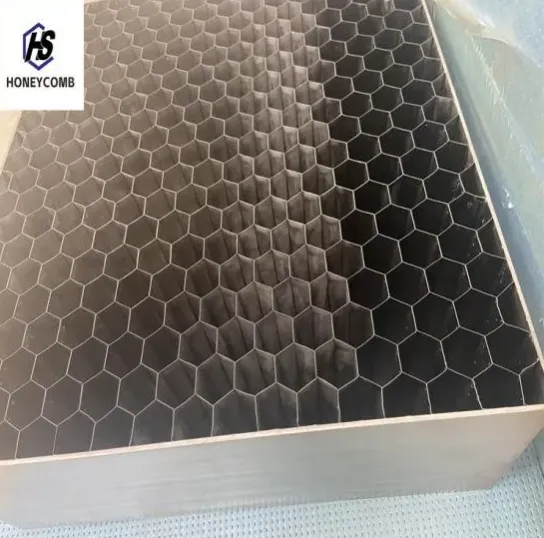

emi honeycomb

Exploring the world of glass technology reveals the fascinating innovation of EMI shielded glass, known in many circles as vetro schermato EMI. In today's digitally driven society where electronic interference is a formidable challenge, the importance of such a product cannot be overstated. This technology is not merely a feat of modern engineering; it is a strategic component in safeguarding sensitive environments against electromagnetic interference (EMI).

Professionals in the field recognize the authoritative edge that EMI shielded glass brings. As an essential component of secure communications, it ensures that signals remain contained within designated environments, fostering secure transmission of information. This capability is particularly significant for governmental agencies and corporate sectors where data integrity is paramount. The expertise behind vetro schermato EMI also capitalizes on the dynamic nature of technological evolution. As electronic devices become more sophisticated and compact, the propensity for interference increases. Hence, continuous innovation in EMI shielding is crucial. Engineers and scientists work in tandem to refine existing technologies and develop newer, more effective solutions. Choosing EMI shielded glass is not merely a purchase; it's an investment in safeguarding critical assets against unseen threats. This product underscores the importance of preventative measures in today's interconnected and technologically reliant world. In offering robust EMI protection, it affords peace of mind, ensuring that operations continue smoothly without the looming threat of interference. In essence, vetro schermato EMI represents a fusion of innovation, trust, and utility. It enshrines the commitment to maintaining a seamless operational environment across industries that cannot afford lapses in functionality due to electronic interference. Therefore, for any entity pondering improving their infrastructure's resilience, embracing EMI shielded glass is a decisively strategic choice.

Professionals in the field recognize the authoritative edge that EMI shielded glass brings. As an essential component of secure communications, it ensures that signals remain contained within designated environments, fostering secure transmission of information. This capability is particularly significant for governmental agencies and corporate sectors where data integrity is paramount. The expertise behind vetro schermato EMI also capitalizes on the dynamic nature of technological evolution. As electronic devices become more sophisticated and compact, the propensity for interference increases. Hence, continuous innovation in EMI shielding is crucial. Engineers and scientists work in tandem to refine existing technologies and develop newer, more effective solutions. Choosing EMI shielded glass is not merely a purchase; it's an investment in safeguarding critical assets against unseen threats. This product underscores the importance of preventative measures in today's interconnected and technologically reliant world. In offering robust EMI protection, it affords peace of mind, ensuring that operations continue smoothly without the looming threat of interference. In essence, vetro schermato EMI represents a fusion of innovation, trust, and utility. It enshrines the commitment to maintaining a seamless operational environment across industries that cannot afford lapses in functionality due to electronic interference. Therefore, for any entity pondering improving their infrastructure's resilience, embracing EMI shielded glass is a decisively strategic choice.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025