- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 10:11

Back to list

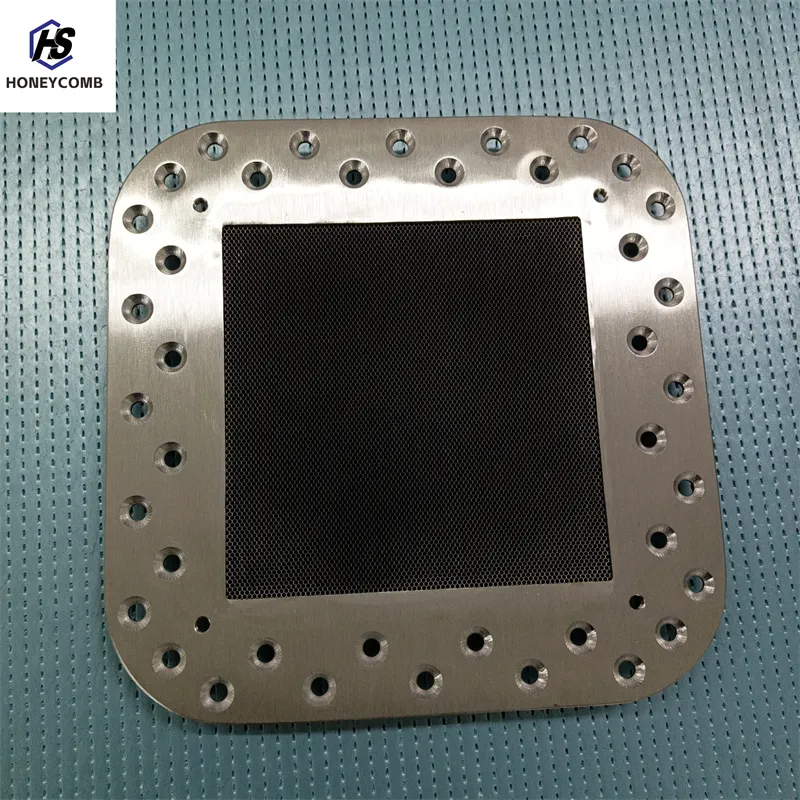

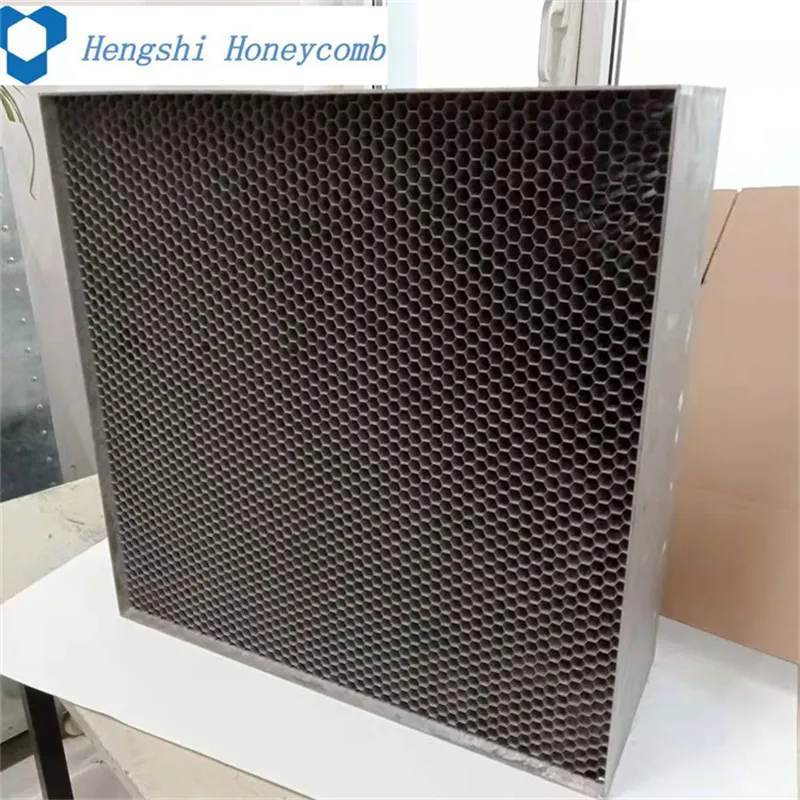

stainless steel honeycomb mesh

Bulletproof glass, a marvel of modern engineering, provides unparalleled security and protection in various settings, from banks and military installations to private residences and vehicles. Given its critical role, understanding the nuances of its design, function, and application is essential not only for manufacturers but also for consumers looking to invest in enhanced safety. My extensive experience in security solutions and deep expertise in materials science have equipped me with insights into the optimal use and selection of bulletproof glass, ensuring that information shared here is both authoritative and trustworthy.

Innovations in the development of bulletproof glass continue to emerge. Recent advances in polymer technology and fiber optics integration have resulted in lighter, more versatile products that do not compromise on strength or clarity. This progress maximizes light transmission and minimizes visual distortion, debunking the myth that security must come at the expense of visibility. Contemporary designs incorporate layers that are thinner and more lightweight, enhancing both the aesthetic and functional aspects of buildings and vehicles. Moreover, the trend towards environmentally conscious production methods in manufacturing bulletproof glass is rising. Recyclable materials and processes that reduce carbon footprints without compromising security standards are becoming prevalent. Choosing manufacturers that prioritize sustainability not only contributes to environmental conservation but also aligns with the corporate social responsibility goals of security-conscious businesses. Trustworthiness in selecting bulletproof glass comes with transparency from manufacturers regarding the testing and certification statuses of their products. Verified compliance with standards such as UL 752, which specifies bulletproof glass performance criteria, endorses credibility and reliability. In conclusion, bulletproof glass remains an indispensable component in modern security strategies. Through informed selection, based on authentic experience and backed by state-of-the-art advancements, its application extends benefits beyond mere safety. Whether for trends in sustainable development or integration within smart security systems, bulletproof glass exemplifies how traditional solutions can evolve to meet the ever-changing demands of security today.

Innovations in the development of bulletproof glass continue to emerge. Recent advances in polymer technology and fiber optics integration have resulted in lighter, more versatile products that do not compromise on strength or clarity. This progress maximizes light transmission and minimizes visual distortion, debunking the myth that security must come at the expense of visibility. Contemporary designs incorporate layers that are thinner and more lightweight, enhancing both the aesthetic and functional aspects of buildings and vehicles. Moreover, the trend towards environmentally conscious production methods in manufacturing bulletproof glass is rising. Recyclable materials and processes that reduce carbon footprints without compromising security standards are becoming prevalent. Choosing manufacturers that prioritize sustainability not only contributes to environmental conservation but also aligns with the corporate social responsibility goals of security-conscious businesses. Trustworthiness in selecting bulletproof glass comes with transparency from manufacturers regarding the testing and certification statuses of their products. Verified compliance with standards such as UL 752, which specifies bulletproof glass performance criteria, endorses credibility and reliability. In conclusion, bulletproof glass remains an indispensable component in modern security strategies. Through informed selection, based on authentic experience and backed by state-of-the-art advancements, its application extends benefits beyond mere safety. Whether for trends in sustainable development or integration within smart security systems, bulletproof glass exemplifies how traditional solutions can evolve to meet the ever-changing demands of security today.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025