- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 23, 2025 01:22

Back to list

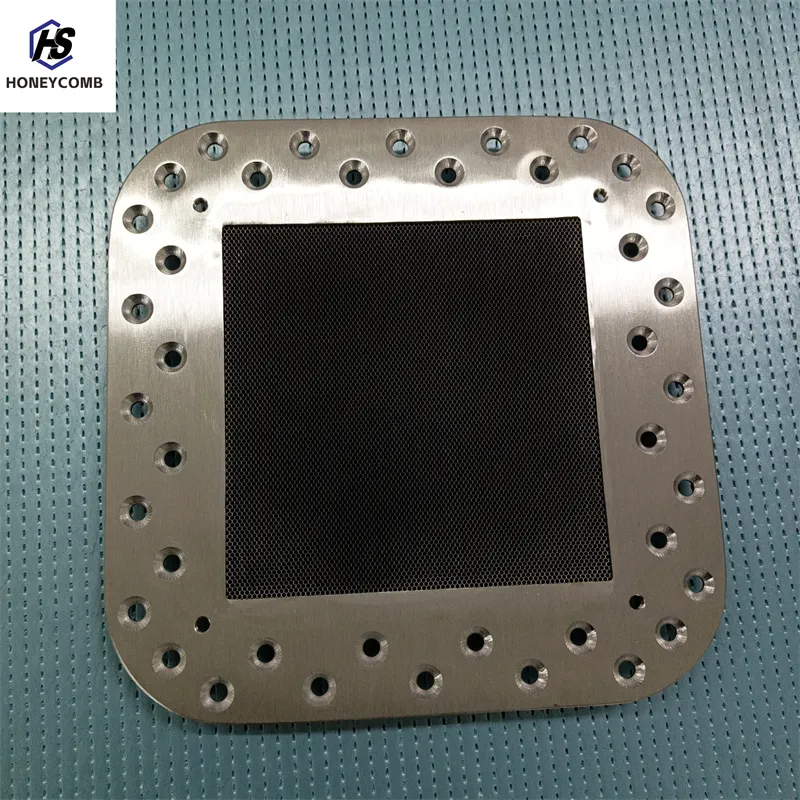

emi honeycomb

EMI honeycomb technology has emerged as a pioneering force in the realm of electromagnetic interference (EMI) shielding, offering unparalleled benefits across various industries. With its unique structural composition and superior performance characteristics, the EMI honeycomb is increasingly becoming the go-to solution for modern electronic applications requiring high fidelity and security.

The authoritative use of EMI honeycomb extends into its ability to complement existing shielding technologies. In scenarios where traditional conductive coatings or metal housings fall short, honeycomb structures provide an extra layer of protection. Engineers often integrate EMI honeycomb with these traditional methods, creating a hybrid solution that capitalizes on the strengths of both. This multifaceted approach not only enhances overall shielding performance but also provides a versatile framework adaptable to future advancements in electronic design. Trustworthiness in EMI honeycomb solutions is evidenced by independent studies and certifications that validate their effectiveness. Rigorous testing environments simulate extreme electromagnetic conditions to ensure that the honeycomb structures perform reliably under pressure. The results from such trials consistently show superior shielding effectiveness over conventional materials, often achieving attenuation levels that significantly exceed required benchmarks. By substantiating these claims through empirical data, manufacturers of EMI honeycomb reinforce confidence among consumers and stakeholders alike. Additionally, the honeycomb structure offers environmental benefits that align with sustainable practices. Many EMI honeycomb solutions use recyclable and non-toxic materials, reducing the overall environmental footprint of electronic devices. This aspect is increasingly important as industries shift towards environmentally conscious production methodologies. Potential customers are assured that their investment supports both technological advancement and ecological sustainability. In summary, the application of EMI honeycomb is not merely a trend but a substantial advancement in the design and manufacturing of interference-resistant technologies. Its lightweight, adaptable, and highly efficient nature positions it as an essential material for future-proofing electronic devices across an array of industries. As more sectors recognize the value it brings, EMI honeycomb is poised to become a cornerstone of electronic innovation, ensuring devices not only meet but exceed modern expectations for performance and reliability.

The authoritative use of EMI honeycomb extends into its ability to complement existing shielding technologies. In scenarios where traditional conductive coatings or metal housings fall short, honeycomb structures provide an extra layer of protection. Engineers often integrate EMI honeycomb with these traditional methods, creating a hybrid solution that capitalizes on the strengths of both. This multifaceted approach not only enhances overall shielding performance but also provides a versatile framework adaptable to future advancements in electronic design. Trustworthiness in EMI honeycomb solutions is evidenced by independent studies and certifications that validate their effectiveness. Rigorous testing environments simulate extreme electromagnetic conditions to ensure that the honeycomb structures perform reliably under pressure. The results from such trials consistently show superior shielding effectiveness over conventional materials, often achieving attenuation levels that significantly exceed required benchmarks. By substantiating these claims through empirical data, manufacturers of EMI honeycomb reinforce confidence among consumers and stakeholders alike. Additionally, the honeycomb structure offers environmental benefits that align with sustainable practices. Many EMI honeycomb solutions use recyclable and non-toxic materials, reducing the overall environmental footprint of electronic devices. This aspect is increasingly important as industries shift towards environmentally conscious production methodologies. Potential customers are assured that their investment supports both technological advancement and ecological sustainability. In summary, the application of EMI honeycomb is not merely a trend but a substantial advancement in the design and manufacturing of interference-resistant technologies. Its lightweight, adaptable, and highly efficient nature positions it as an essential material for future-proofing electronic devices across an array of industries. As more sectors recognize the value it brings, EMI honeycomb is poised to become a cornerstone of electronic innovation, ensuring devices not only meet but exceed modern expectations for performance and reliability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025