- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 23, 2025 01:00

Back to list

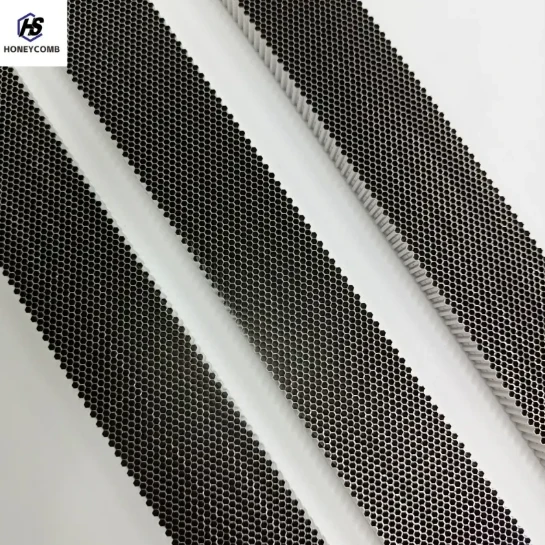

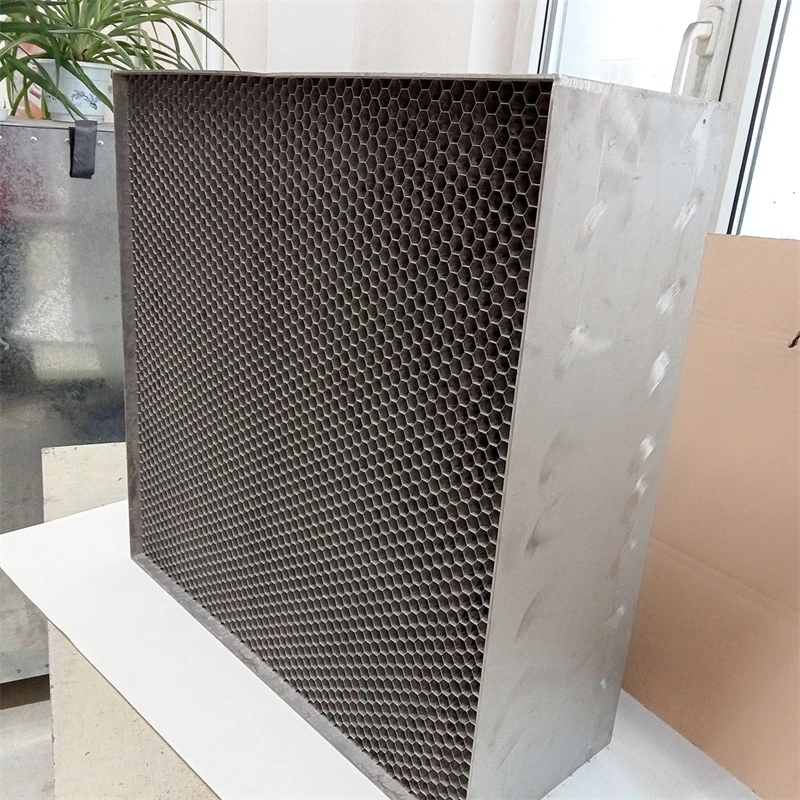

emi rfi shielded waveguide air vents

In the rapidly advancing world of electronics and communication, ensuring optimal functionality of sensitive equipment necessitates the implementation of efficient electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding solutions. This need is critical in environments where minimizing interference is paramount to performance, reliability, and safety. One of the most effective solutions for addressing such challenges is the use of EMI RFI shielded waveguide air vents.

Moreover, the expertise of these manufacturers extends beyond just the creation of effective EMI/RFI shielding solutions. They also offer advisory services, which include site assessments to identify potential EMI/RFI sources and developing comprehensive mitigation strategies. Such in-depth knowledge and authoritative insights contribute significantly to drawing conclusions and implementing improvements that safeguard operational integrity, commanding confidence and trust from clients worldwide. One real-world example reflecting the importance of EMI RFI shielded waveguide air vents is evident in secure government and military installations. In these settings, secure and uninterrupted communication is critical. Fluctuations or disruptions can have severe consequences, underscoring the need for robust protective measures. When incorporating shielded air vents, these facilities achieve heightened levels of electromagnetic protection, which is crucial for maintaining secure communications. To ensure you are making an informed decision when selecting an EMI RFI shielded waveguide air vent, it is essential to consider certain factors such as the frequency range of operation, ventilation needs, shielding effectiveness, and material properties. Consulting with industry experts who possess a comprehensive understanding of these solutions can help design an effective shielding strategy that aligns with specific requirements. In conclusion, the necessity for EMI RFI shielded waveguide air vents in our increasingly connected world cannot be overstated. These components are not just products, but vital elements of any facility seeking to reduce interference, secure communications, and ensure the reliability of sophisticated electronic systems. Leveraging the experience and authority of seasoned industry experts aids in acquiring and deploying the correct shielding solutions, ultimately safeguarding infrastructure from electromagnetic anomalies.

Moreover, the expertise of these manufacturers extends beyond just the creation of effective EMI/RFI shielding solutions. They also offer advisory services, which include site assessments to identify potential EMI/RFI sources and developing comprehensive mitigation strategies. Such in-depth knowledge and authoritative insights contribute significantly to drawing conclusions and implementing improvements that safeguard operational integrity, commanding confidence and trust from clients worldwide. One real-world example reflecting the importance of EMI RFI shielded waveguide air vents is evident in secure government and military installations. In these settings, secure and uninterrupted communication is critical. Fluctuations or disruptions can have severe consequences, underscoring the need for robust protective measures. When incorporating shielded air vents, these facilities achieve heightened levels of electromagnetic protection, which is crucial for maintaining secure communications. To ensure you are making an informed decision when selecting an EMI RFI shielded waveguide air vent, it is essential to consider certain factors such as the frequency range of operation, ventilation needs, shielding effectiveness, and material properties. Consulting with industry experts who possess a comprehensive understanding of these solutions can help design an effective shielding strategy that aligns with specific requirements. In conclusion, the necessity for EMI RFI shielded waveguide air vents in our increasingly connected world cannot be overstated. These components are not just products, but vital elements of any facility seeking to reduce interference, secure communications, and ensure the reliability of sophisticated electronic systems. Leveraging the experience and authority of seasoned industry experts aids in acquiring and deploying the correct shielding solutions, ultimately safeguarding infrastructure from electromagnetic anomalies.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025