- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 03:49

Back to list

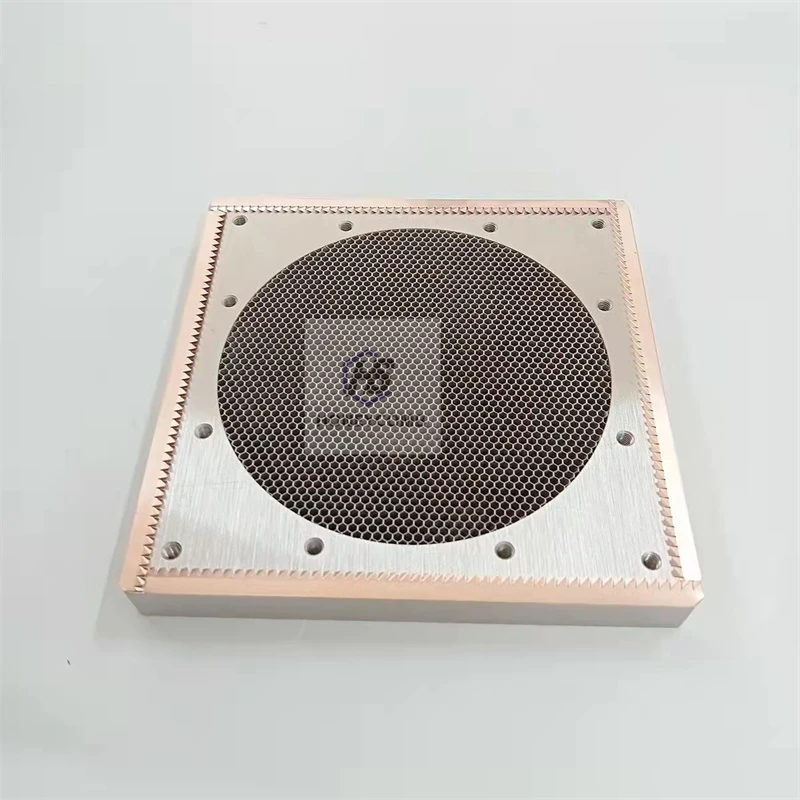

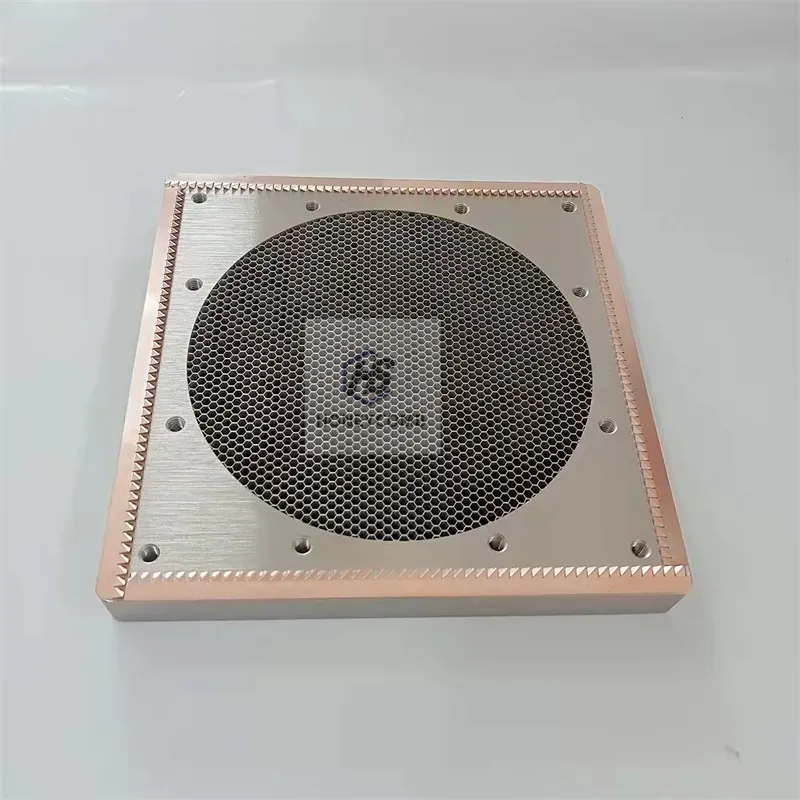

emi honeycomb

For industries navigating the complex landscape of electromagnetic interference (EMI) and radio frequency interference (RFI), shielded waveguide air vents present a cornerstone solution. These meticulously engineered components serve as protective barriers, ensuring the safe transmission of signals while safeguarding sensitive electronic environments from disruptive interferences.

Manufacturers of shielded waveguide air vents bring an authoritative skill set, cultivated through years of R&D and empirical data-backed strategies. Their production processes involve the meticulous selection of materials, which are rigorously tested for conductivity, permeability, and mechanical stability. Such expertise guarantees that the end product not only meets but often exceeds, regulatory standards. The authoritative know-how also extends to the customization of designs to accommodate varying environmental and technical challenges faced by specific industries. Trustworthiness in this sphere is not merely an attribute but a critical requirement. Clients across industries seek suppliers whose products have consistently demonstrated reliability under real-world conditions. This reliability is bolstered through certifications and third-party testing that validate performance claims. By leveraging documented success stories and case studies, manufacturers can effectively communicate their solutions’ reliability to prospective clients, thereby solidifying their reputation within the market. In essence, shielded waveguide air vents epitomize a blend of robust engineering and practical application, affording industries a reliable solution to EMI/RFI challenges without compromising on essential ventilation needs. They are a testament to the collective expertise, authority, and trust that manufacturers and engineers cultivate and demonstrate daily. Through continuous innovation and adherence to stringent standards, they provide a formidable line of defense in the ceaseless battle against electromagnetic interference, safeguarding operations today and well into the future.

Manufacturers of shielded waveguide air vents bring an authoritative skill set, cultivated through years of R&D and empirical data-backed strategies. Their production processes involve the meticulous selection of materials, which are rigorously tested for conductivity, permeability, and mechanical stability. Such expertise guarantees that the end product not only meets but often exceeds, regulatory standards. The authoritative know-how also extends to the customization of designs to accommodate varying environmental and technical challenges faced by specific industries. Trustworthiness in this sphere is not merely an attribute but a critical requirement. Clients across industries seek suppliers whose products have consistently demonstrated reliability under real-world conditions. This reliability is bolstered through certifications and third-party testing that validate performance claims. By leveraging documented success stories and case studies, manufacturers can effectively communicate their solutions’ reliability to prospective clients, thereby solidifying their reputation within the market. In essence, shielded waveguide air vents epitomize a blend of robust engineering and practical application, affording industries a reliable solution to EMI/RFI challenges without compromising on essential ventilation needs. They are a testament to the collective expertise, authority, and trust that manufacturers and engineers cultivate and demonstrate daily. Through continuous innovation and adherence to stringent standards, they provide a formidable line of defense in the ceaseless battle against electromagnetic interference, safeguarding operations today and well into the future.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025