- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 04:22

Back to list

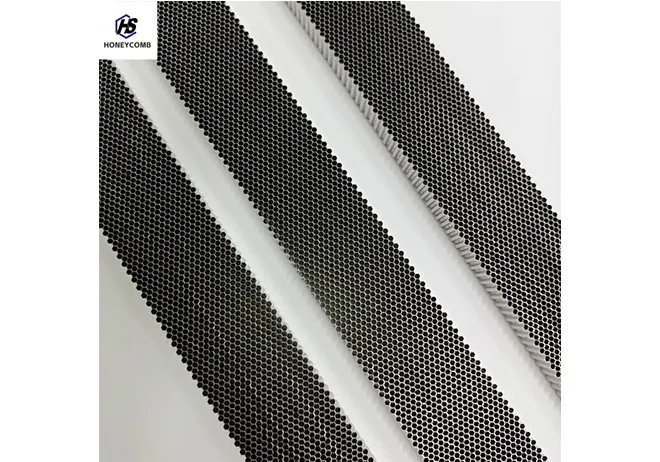

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

Navigating the modern landscape of air management, the term luftriktarens intag has garnered significant attention, especially among those looking to enhance air intake systems in various applications. This Swedish term translates to air director intake, a concept that goes beyond mere functionality, incorporating advanced design and engineering principles to optimize air flow in engines, HVAC units, and even industrial applications.

Trust in air director intake technologies is further reinforced by rigorous testing standards and certifications. Products that meet ISO and other international standards offer a level of assurance to consumers and industry professionals alike, signifying reliability and performance. These certifications often entail thorough testing procedures that simulate real-world conditions, ensuring that the systems will perform optimally under varying scenarios. Additional authority in the field comes from continuous professional development and expertise-sharing within the scientific and engineering communities. Conferences, workshops, and peer-reviewed publications foster a culture of innovation and improvement, assuring that advancements in air director intake technology are well-documented and supported by solid empirical data. For consumers and businesses seeking to invest in air director intake technology, it is vital to prioritize providers and manufacturers who prioritize both innovation and quality assurance. Engaging with companies that have a proven track record and possess accreditations from recognized industry bodies can make a significant difference. Alongside this, seeking feedback and experiences from other users can provide insights into the practical benefits and potential challenges associated with specific systems. In conclusion, the luftriktarens intag represents a sophisticated blend of engineering expertise and cutting-edge technology, aiming to revolutionize air intake systems across various applications. By emphasizing performance, reliability, and adaptability, these systems not only meet current demands but also set a precedent for future advancements in air management technologies. Whether for automotive, HVAC, or industrial use, embracing the potential of air director intakes can lead to substantial improvements in efficiency and sustainability.

Trust in air director intake technologies is further reinforced by rigorous testing standards and certifications. Products that meet ISO and other international standards offer a level of assurance to consumers and industry professionals alike, signifying reliability and performance. These certifications often entail thorough testing procedures that simulate real-world conditions, ensuring that the systems will perform optimally under varying scenarios. Additional authority in the field comes from continuous professional development and expertise-sharing within the scientific and engineering communities. Conferences, workshops, and peer-reviewed publications foster a culture of innovation and improvement, assuring that advancements in air director intake technology are well-documented and supported by solid empirical data. For consumers and businesses seeking to invest in air director intake technology, it is vital to prioritize providers and manufacturers who prioritize both innovation and quality assurance. Engaging with companies that have a proven track record and possess accreditations from recognized industry bodies can make a significant difference. Alongside this, seeking feedback and experiences from other users can provide insights into the practical benefits and potential challenges associated with specific systems. In conclusion, the luftriktarens intag represents a sophisticated blend of engineering expertise and cutting-edge technology, aiming to revolutionize air intake systems across various applications. By emphasizing performance, reliability, and adaptability, these systems not only meet current demands but also set a precedent for future advancements in air management technologies. Whether for automotive, HVAC, or industrial use, embracing the potential of air director intakes can lead to substantial improvements in efficiency and sustainability.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025