- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 03:03

Back to list

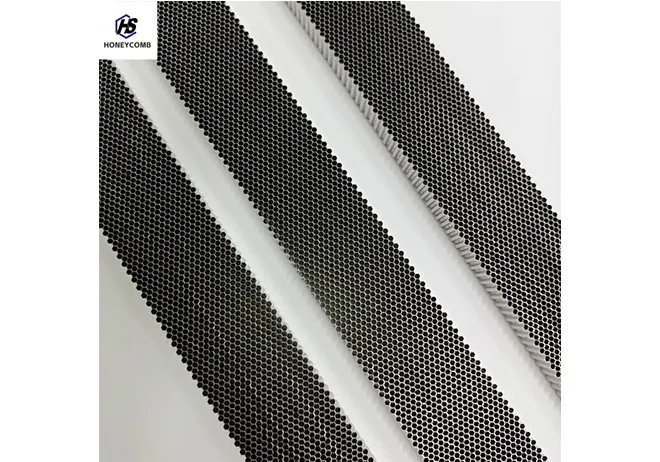

emi honeycomb

The landscape of modern engineering and technology is ever-evolving, with components continually being refined to maximize efficiency and performance. Among these critical components, the EMI ventiler stands out as a fundamental player in managing electromagnetic interference in various applications. Through years of research and practical application, the value of EMI ventilers has become increasingly recognized in both consumer and industrial electronics.

The process of integrating EMI ventilers into a system is intricate and demands an authoritative understanding of both the product and the system it is meant to protect. Experts stress the importance of thorough testing and customization to align the ventiler's specifications with operational requirements. This process typically involves an iterative approach where prototypes undergo electromagnetic compatibility (EMC) testing until they meet the desired parameters. Trustworthiness in the efficacy of EMI ventilers also stems from rigorous compliance with international standards. Compliance with standards such as IEC 61000 or MIL-STD-461 ensures that the ventilers can withstand specific interference levels and frequency ranges. Manufacturers with a track record of independently verified compliance provide assurance of product reliability and performance. In the realm of consumer electronics, EMI ventilers contribute significantly to product longevity and user satisfaction. By reducing electromagnetic interference, these ventilers help maintain the smooth operation of devices such as smartphones, televisions, and wireless routers. Industry experts agree that as devices continue to incorporate more features and connectivity options, the role of EMI ventilers will only grow in importance. In conclusion, EMI ventilers represent a fusion of advanced engineering and practical application, showcasing expertise across multiple disciplines. Their ability to protect sensitive electronics from the ravages of electromagnetic interference while facilitating cooling makes them a cornerstone of modern technological infrastructure. Through continued innovation and compliance with stringent standards, they maintain their authoritative position as an essential component in the toolkit of both engineers and manufacturers striving towards optimal system performance.

The process of integrating EMI ventilers into a system is intricate and demands an authoritative understanding of both the product and the system it is meant to protect. Experts stress the importance of thorough testing and customization to align the ventiler's specifications with operational requirements. This process typically involves an iterative approach where prototypes undergo electromagnetic compatibility (EMC) testing until they meet the desired parameters. Trustworthiness in the efficacy of EMI ventilers also stems from rigorous compliance with international standards. Compliance with standards such as IEC 61000 or MIL-STD-461 ensures that the ventilers can withstand specific interference levels and frequency ranges. Manufacturers with a track record of independently verified compliance provide assurance of product reliability and performance. In the realm of consumer electronics, EMI ventilers contribute significantly to product longevity and user satisfaction. By reducing electromagnetic interference, these ventilers help maintain the smooth operation of devices such as smartphones, televisions, and wireless routers. Industry experts agree that as devices continue to incorporate more features and connectivity options, the role of EMI ventilers will only grow in importance. In conclusion, EMI ventilers represent a fusion of advanced engineering and practical application, showcasing expertise across multiple disciplines. Their ability to protect sensitive electronics from the ravages of electromagnetic interference while facilitating cooling makes them a cornerstone of modern technological infrastructure. Through continued innovation and compliance with stringent standards, they maintain their authoritative position as an essential component in the toolkit of both engineers and manufacturers striving towards optimal system performance.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025