- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 02:41

Back to list

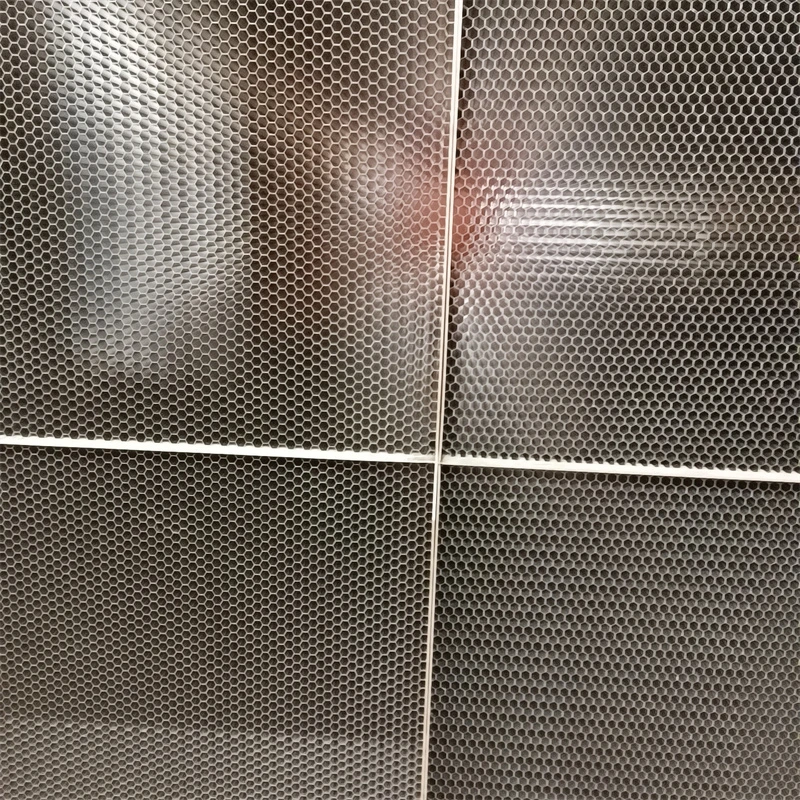

honeycomb seal turbine

Choosing the right ventilation solutions for various applications requires a blend of modern engineering and practical sensibility. Ventilated aluminum honeycomb panels stand as one of the optimal choices, offering an impeccable combination of durability, lightweight structure, and superior aesthetic appeal. This article delves into the world of ventilated aluminum honeycomb panels, exploring their real-world benefits, the expertise behind their design, and their authoritative status in the construction industry.

Trust in ventilated aluminum honeycomb panels is bolstered by third-party certifications that testify to their performance metrics. Compliance with international standards such as ISO 9001 and ASTM verifies the material's reliability, reinforcing its reputation among professionals. Moreover, feedback from seasoned installers and users further emphasizes their long-term dependability and resilience against challenging conditions, building confidence among prospective buyers. Integrating ventilated aluminum honeycomb panels into projects is not just a testament to an understanding of advanced materials; it also reflects a commitment to sustainability and modern design efficiencies. These panels are recyclable, minimizing their environmental impact and aligning with green building practices. Their lightweight nature contributes to reduced transportation costs and effort, while their durability ensures they remain a fixture in buildings for decades, reducing the need for frequent replacements. To conclude, ventilated aluminum honeycomb panels are more than just a construction material; they exemplify the principles of innovation, resilience, and sustainability. With practical applications across numerous industries complemented by cutting-edge expertise in their manufacturing, they remain an authoritative choice for any project that demands the highest standards of quality and efficiency. By integrating these panels, professionals endorse a material that offers trust and performance, ensuring their projects stand the test of time.

Trust in ventilated aluminum honeycomb panels is bolstered by third-party certifications that testify to their performance metrics. Compliance with international standards such as ISO 9001 and ASTM verifies the material's reliability, reinforcing its reputation among professionals. Moreover, feedback from seasoned installers and users further emphasizes their long-term dependability and resilience against challenging conditions, building confidence among prospective buyers. Integrating ventilated aluminum honeycomb panels into projects is not just a testament to an understanding of advanced materials; it also reflects a commitment to sustainability and modern design efficiencies. These panels are recyclable, minimizing their environmental impact and aligning with green building practices. Their lightweight nature contributes to reduced transportation costs and effort, while their durability ensures they remain a fixture in buildings for decades, reducing the need for frequent replacements. To conclude, ventilated aluminum honeycomb panels are more than just a construction material; they exemplify the principles of innovation, resilience, and sustainability. With practical applications across numerous industries complemented by cutting-edge expertise in their manufacturing, they remain an authoritative choice for any project that demands the highest standards of quality and efficiency. By integrating these panels, professionals endorse a material that offers trust and performance, ensuring their projects stand the test of time.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025