- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 06, 2025 17:37

Back to list

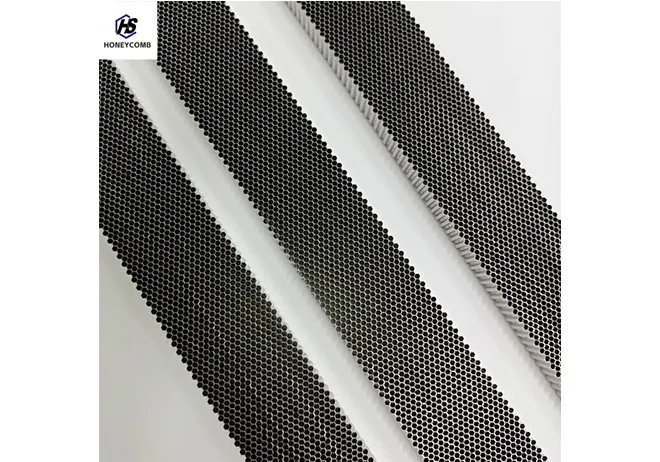

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

In the ever-evolving world of industrial and commercial fluid management, the term endireitador de fluxo has started gaining prominence. This vital component, known as a flow straightener in English, plays an essential role in various fields such as petrochemicals, water treatment, and HVAC systems. Understanding its functionalities and benefits can make a significant difference in optimizing system efficiency and reliability.

Establishing authority in this domain involves showcasing a solid track record of successful implementations and satisfied clients. Companies specializing in flow management solutions often provide detailed case studies and testimonials, highlighting scenarios where flow straighteners have markedly improved processes. For instance, in the oil and gas industry, deploying flow straighteners in pipeline systems has resulted in more efficient transport of crude oil and refined products, reducing energy consumption and lowering operational costs significantly. Trustworthiness is built through transparency and accountability. Reputable manufacturers and suppliers offer comprehensive warranties and support services, ensuring their clients have the necessary resources and assistance post-installation. Furthermore, adherence to industry standards and certifications acts as a testament to the quality and reliability of their products. Organizations investing in flow straighteners can take confidence from these certifications, knowing they are obtaining components that meet rigorous safety and performance criteria. When considering the integration of a flow straightener, it is essential to conduct a thorough evaluation of the system's requirements and constraints. Consulting with experts and leveraging computational fluid dynamics (CFD) simulations can aid in selecting the optimal solution tailored to specific needs. Such thorough analysis helps in identifying potential challenges and customizing the design for maximum efficiency, ensuring the investment yields tangible returns. In conclusion, the endireitador de fluxo is more than just a component—it is a strategic enhancement to fluid management systems that offers improved efficiency, cost savings, and reliability. As industries strive for higher performance and sustainability, integrating such innovative solutions becomes not only beneficial but necessary. By understanding the comprehensive advantages and best practices associated with flow straighteners, businesses can make informed decisions that drive long-term success and operational excellence.

Establishing authority in this domain involves showcasing a solid track record of successful implementations and satisfied clients. Companies specializing in flow management solutions often provide detailed case studies and testimonials, highlighting scenarios where flow straighteners have markedly improved processes. For instance, in the oil and gas industry, deploying flow straighteners in pipeline systems has resulted in more efficient transport of crude oil and refined products, reducing energy consumption and lowering operational costs significantly. Trustworthiness is built through transparency and accountability. Reputable manufacturers and suppliers offer comprehensive warranties and support services, ensuring their clients have the necessary resources and assistance post-installation. Furthermore, adherence to industry standards and certifications acts as a testament to the quality and reliability of their products. Organizations investing in flow straighteners can take confidence from these certifications, knowing they are obtaining components that meet rigorous safety and performance criteria. When considering the integration of a flow straightener, it is essential to conduct a thorough evaluation of the system's requirements and constraints. Consulting with experts and leveraging computational fluid dynamics (CFD) simulations can aid in selecting the optimal solution tailored to specific needs. Such thorough analysis helps in identifying potential challenges and customizing the design for maximum efficiency, ensuring the investment yields tangible returns. In conclusion, the endireitador de fluxo is more than just a component—it is a strategic enhancement to fluid management systems that offers improved efficiency, cost savings, and reliability. As industries strive for higher performance and sustainability, integrating such innovative solutions becomes not only beneficial but necessary. By understanding the comprehensive advantages and best practices associated with flow straighteners, businesses can make informed decisions that drive long-term success and operational excellence.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025