- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 07, 2025 00:38

Back to list

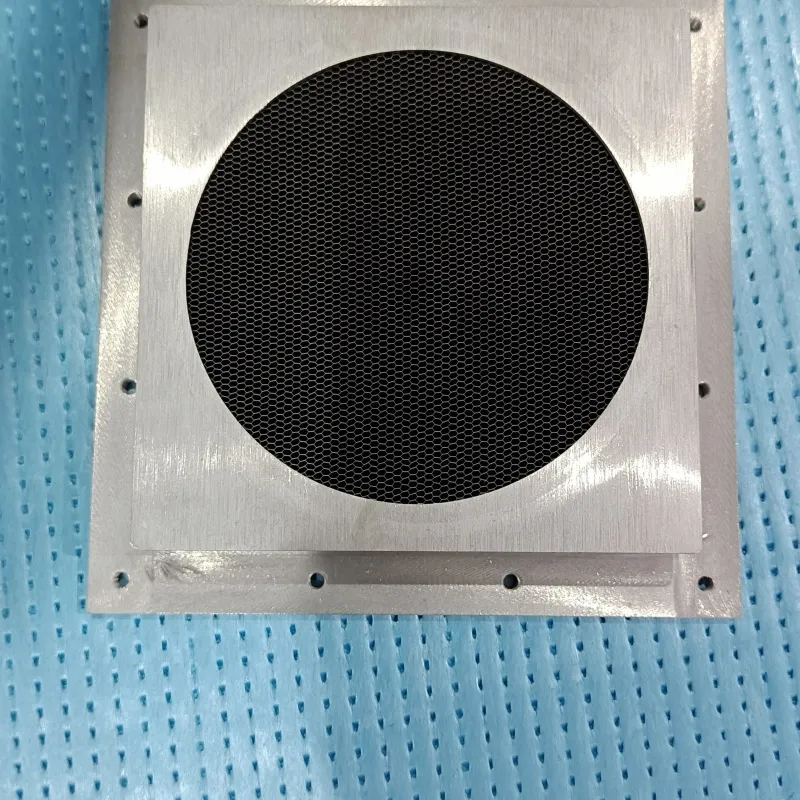

painéis favo de mel

Understanding the advantages and applications of honeycomb panels is crucial for businesses and consumers looking for efficient solutions in construction, design, and various industries. As a long-time industry expert, I’ve seen firsthand how these innovative panels have transformed modern architecture and design.

The sustainability of honeycomb panels cannot be overstated. Made from recyclable materials like aluminum, they support circular economic practices. I’ve collaborated on several projects where recycling programs reduce waste and support local economies by creating jobs in the recycling sector. The lifecycle of these panels often aligns with green building certifications, helping companies meet regulatory standards and appeal to eco-conscious consumers. Another significant benefit is the ease of installation and maintenance. Their lightweight nature reduces transportation and labor costs. Installers find the panels user-friendly, often leading to lower accident rates on site. This aspect contributes to their reputation as a practical and safe material choice for both large-scale and residential projects. I recall a notable project involving a coastal retreat where honeycomb panels were chosen to address specific environmental conditions, such as salt air corrosion and high winds. The project's success was a testament to the panels' adaptability and resilience, setting a precedent for future constructions in similar locales. From an economic standpoint, the initial investment in honeycomb panels might seem substantial. However, their long-term cost savings, attributed to decreased maintenance requirements and enhanced energy efficiency, quickly recoup the initial outlay. Companies consistently report a positive return on investment, validating the panels as not only a smart environmental choice but also a savvy financial decision. Honeycomb panels continue to gain credence across industries due to their undeniable advantages in sustainability, efficiency, and performance. Their widespread application is a clear indicator of their pivotal role in addressing modern engineering challenges. As industries evolve, these panels will undoubtedly remain at the forefront of innovation, inspiring new applications and furthering the goals of a sustainable future.

The sustainability of honeycomb panels cannot be overstated. Made from recyclable materials like aluminum, they support circular economic practices. I’ve collaborated on several projects where recycling programs reduce waste and support local economies by creating jobs in the recycling sector. The lifecycle of these panels often aligns with green building certifications, helping companies meet regulatory standards and appeal to eco-conscious consumers. Another significant benefit is the ease of installation and maintenance. Their lightweight nature reduces transportation and labor costs. Installers find the panels user-friendly, often leading to lower accident rates on site. This aspect contributes to their reputation as a practical and safe material choice for both large-scale and residential projects. I recall a notable project involving a coastal retreat where honeycomb panels were chosen to address specific environmental conditions, such as salt air corrosion and high winds. The project's success was a testament to the panels' adaptability and resilience, setting a precedent for future constructions in similar locales. From an economic standpoint, the initial investment in honeycomb panels might seem substantial. However, their long-term cost savings, attributed to decreased maintenance requirements and enhanced energy efficiency, quickly recoup the initial outlay. Companies consistently report a positive return on investment, validating the panels as not only a smart environmental choice but also a savvy financial decision. Honeycomb panels continue to gain credence across industries due to their undeniable advantages in sustainability, efficiency, and performance. Their widespread application is a clear indicator of their pivotal role in addressing modern engineering challenges. As industries evolve, these panels will undoubtedly remain at the forefront of innovation, inspiring new applications and furthering the goals of a sustainable future.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025