- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 10, 2025 10:59

Back to list

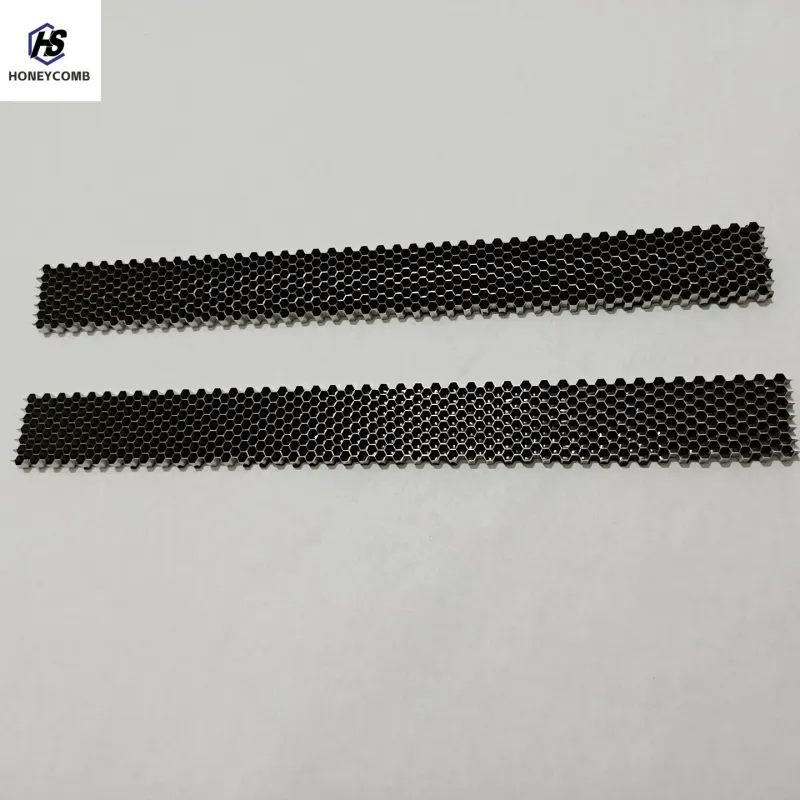

extrudierte aluminiumwabe

In the field of modern construction and manufacturing, the use of extruded aluminum honeycomb structures has garnered significant attention due to their exceptional combination of strength, lightness, and versatility. This innovative material is rapidly becoming a cornerstone in sectors ranging from aerospace to architecture, where performance and efficiency are paramount.

The adaptability of extruded aluminum honeycomb structures is another aspect of their allure. Manufacturers can modify the thickness, cell size, and alloy composition to meet specific requirements, providing tailored solutions for diverse industrial needs. Whether used in aerospace components, automotive structures, or building facades, this versatility is unmatchable, supporting innovative design without compromising structural integrity. From an expertise standpoint, industry leaders often turn to extruded aluminum honeycomb for its proven track record in challenging environments. Studies have shown that these structures maintain their integrity under various stress tests, offering reliability in critical applications such as aircraft interiors and automotive crash zones, where safety is the utmost priority. The consistent delivery of high performance under duress speaks volumes about the material's engineered excellence. When considering the authoritativeness of extruded aluminum honeycomb, one must acknowledge the ongoing research and development aimed at optimizing this material for future applications. Institutions and organizations globally are investing in advancements that seek to enhance the mechanical properties, improve production efficiencies, and explore new applications. This continuous innovation ensures that extruded aluminum honeycomb remains at the forefront of modern material science and engineering. From a trustworthiness perspective, extruded aluminum honeycomb has gained accreditation from various industry standards organizations, which endorse its performance characteristics. Certification from reputable bodies provides end-users with confidence that these materials meet or exceed safety and quality benchmarks, essential for industries where risk mitigation is crucial. In summary, the benefits of extruded aluminum honeycombs go beyond mere innovation. They represent a blend of advanced engineering and practical functionality. As industries continue to push the boundaries of what is possible, this remarkable material bases its reputation on proven performance, adaptability, and a commitment to sustainability. Whether in the sky, on the road, or integrated into the very walls around us, extruded aluminum honeycomb stands as a testimony to cutting-edge design and enduring reliability.

The adaptability of extruded aluminum honeycomb structures is another aspect of their allure. Manufacturers can modify the thickness, cell size, and alloy composition to meet specific requirements, providing tailored solutions for diverse industrial needs. Whether used in aerospace components, automotive structures, or building facades, this versatility is unmatchable, supporting innovative design without compromising structural integrity. From an expertise standpoint, industry leaders often turn to extruded aluminum honeycomb for its proven track record in challenging environments. Studies have shown that these structures maintain their integrity under various stress tests, offering reliability in critical applications such as aircraft interiors and automotive crash zones, where safety is the utmost priority. The consistent delivery of high performance under duress speaks volumes about the material's engineered excellence. When considering the authoritativeness of extruded aluminum honeycomb, one must acknowledge the ongoing research and development aimed at optimizing this material for future applications. Institutions and organizations globally are investing in advancements that seek to enhance the mechanical properties, improve production efficiencies, and explore new applications. This continuous innovation ensures that extruded aluminum honeycomb remains at the forefront of modern material science and engineering. From a trustworthiness perspective, extruded aluminum honeycomb has gained accreditation from various industry standards organizations, which endorse its performance characteristics. Certification from reputable bodies provides end-users with confidence that these materials meet or exceed safety and quality benchmarks, essential for industries where risk mitigation is crucial. In summary, the benefits of extruded aluminum honeycombs go beyond mere innovation. They represent a blend of advanced engineering and practical functionality. As industries continue to push the boundaries of what is possible, this remarkable material bases its reputation on proven performance, adaptability, and a commitment to sustainability. Whether in the sky, on the road, or integrated into the very walls around us, extruded aluminum honeycomb stands as a testimony to cutting-edge design and enduring reliability.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025