- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Stainless Steel Air Flow Straightener - Hengshi | Aerodynamic Testing, EMI Shielding

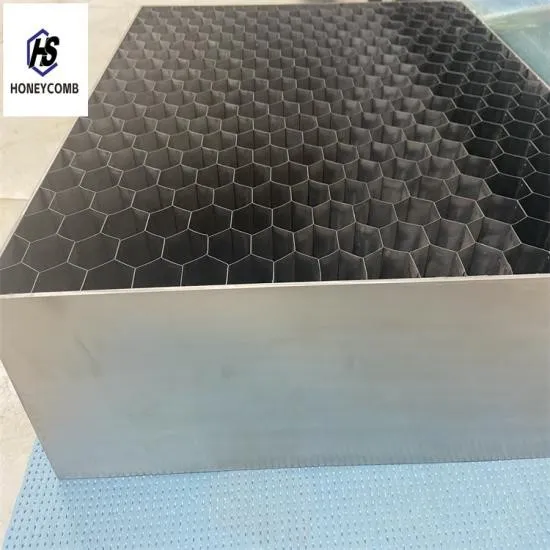

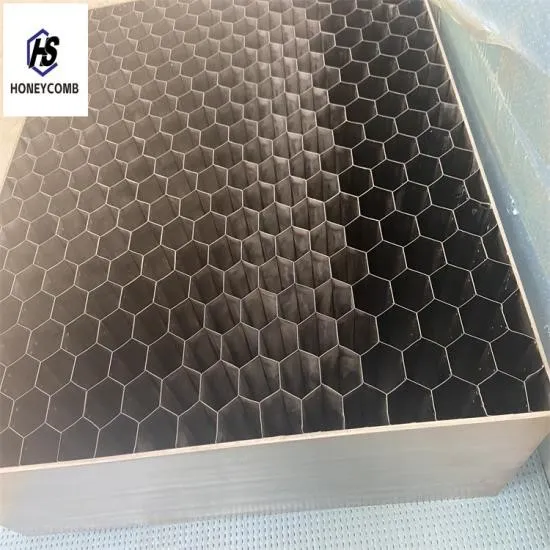

At the intersection of engineering excellence and aerodynamic precision lies the Honeycomb Stainless Steel Air Flow Straightener, a critical component in modern wind tunnel systems and industrial airflow management. Developed by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., this product exemplifies the fusion of advanced materials and cutting-edge design to meet the demands of aerospace, automotive, and environmental testing. This article explores the product’s core functionalities, technical specifications, and its role in shaping the future of aerodynamic research.

Product Introduction: The Evolution of Airflow Stabilization

The Honeycomb Air Flow Straightener has been a cornerstone of airflow stabilization for decades. Originally designed to transform turbulent airflows into laminar flow, this technology is now indispensable in industries ranging from aerospace to renewable energy. The product’s honeycomb structure, composed of meticulously arranged cells, ensures uniform airflow distribution while minimizing pressure drops and turbulence. This innovation is particularly vital in wind tunnels, where accurate aerodynamic measurements are paramount.

According to the National Institute of Standards and Technology (NIST), "Precision in airflow measurement is critical for validating aerodynamic models and ensuring the safety of high-speed vehicles." The honeycomb straightener’s ability to achieve a 95-99% open area makes it a preferred choice for applications requiring minimal flow resistance and maximum accuracy.

Key Features and Technical Specifications

The Honeycomb Stainless Steel Air Flow Straightener is engineered to deliver unmatched performance. Below is a detailed overview of its specifications:

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, ..., 6.0, 8, 10, 12, 20, 30mm (as required) |

| Thickness | Customized |

| Shape | Customized (as required) |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defence, gas seals, communications, medical, and other industries. |

The product’s versatility is further enhanced by its ability to be customized in terms of size, material, and surface treatment. For instance, 304 stainless steel is ideal for high-temperature environments, while 316L offers superior corrosion resistance in marine applications. The RoHS certification ensures compliance with environmental standards, making it a sustainable choice for global industries.

Applications: Beyond Wind Tunnels

The Honeycomb Air Flow Straightener is not confined to wind tunnel systems alone. Its applications span across multiple sectors, including:

- Aerospace: Testing aircraft, missiles, and satellites for aerodynamic efficiency and structural integrity.

- Automotive: Evaluating vehicle aerodynamics, reducing drag, and improving fuel efficiency.

- Renewable Energy: Optimizing wind turbine blade performance and ensuring structural stability.

- Defense: Enhancing the accuracy of missile guidance systems and surveillance equipment.

- Medical: Supporting high-precision airflow control in diagnostic and therapeutic devices.

As noted by NIST, "The integration of advanced materials in industrial testing equipment has revolutionized the way we validate designs and ensure safety." The honeycomb straightener’s role in these applications underscores its importance in modern engineering practices.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Founded as a leader in the production of high-quality shielding products, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a trusted name in the global market. The company specializes in manufacturing honeycomb air flow straighteners, ventilation panels, and honeycomb seals, all designed to meet stringent industry standards.

Hengshi’s commitment to quality is reflected in its ISO9001 certification, which ensures adherence to international quality management systems. The company’s state-of-the-art facilities and skilled engineers enable it to deliver customized solutions tailored to the unique needs of its clients. As highlighted in a NIST report on manufacturing excellence, "Companies that prioritize innovation and quality control are better positioned to meet the evolving demands of global industries."

Advantages of the Honeycomb Air Flow Straightener

The Honeycomb Stainless Steel Air Flow Straightener offers several distinct advantages:

- Enhanced Accuracy: The honeycomb structure minimizes turbulence, ensuring precise airflow measurements in wind tunnels and industrial settings.

- Low Pressure Drop: With a 95-99% open area, the product reduces energy loss and improves system efficiency.

- Corrosion Resistance: Available in materials like 316L stainless steel, it withstands harsh environments, including marine and chemical exposure.

- Customization: The ability to tailor dimensions, materials, and surface treatments ensures compatibility with diverse applications.

- Environmental Compliance: RoHS certification aligns with global sustainability goals, making it a responsible choice for eco-conscious industries.

These advantages are further validated by NIST’s emphasis on "the importance of material selection and design optimization in achieving long-term reliability and performance."

Conclusion: Pioneering the Future of Aerodynamic Testing

The Honeycomb Stainless Steel Air Flow Straightener stands as a testament to the power of precision engineering. From its role in wind tunnel testing to its applications in aerospace and renewable energy, this product continues to drive innovation across industries. Backed by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.’s commitment to quality and sustainability, it sets a new benchmark for airflow management solutions.

As technology advances, the demand for accurate and reliable testing equipment will only grow. The honeycomb air flow straightener, with its unmatched performance and versatility, is poised to remain a cornerstone of aerodynamic research and industrial applications for years to come.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. https://www.nist.gov

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.. (n.d.). Product Catalog. https://www.hshihoneycomb.com

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025