- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Stainless Steel Air Flow Straightener-Hengshi|Enhance Wind Tunnel Efficiency&Precision Control

Honeycomb Stainless Steel Air Flow Straightener: Enhancing Wind Tunnel Efficiency

At Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., we specialize in providing advanced solutions for industrial airflow control. Our Honeycomb Stainless Steel Air Flow Straightener is designed to optimize wind tunnel performance, ensuring precise and stable airflow for a wide range of applications. This article explores the product's features, technical specifications, and benefits, highlighting how it addresses industry challenges and delivers value to our clients.

Product Overview

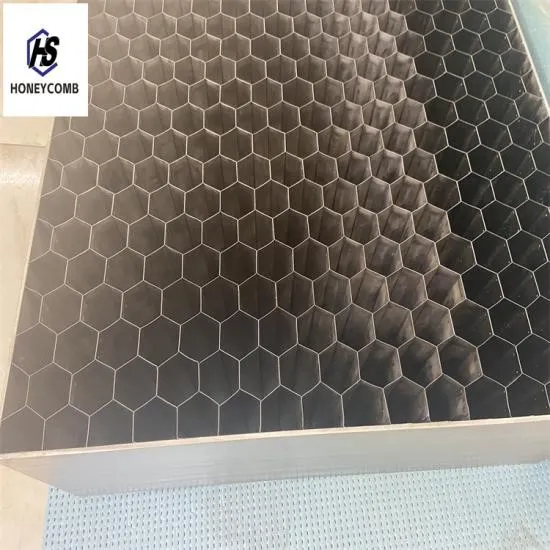

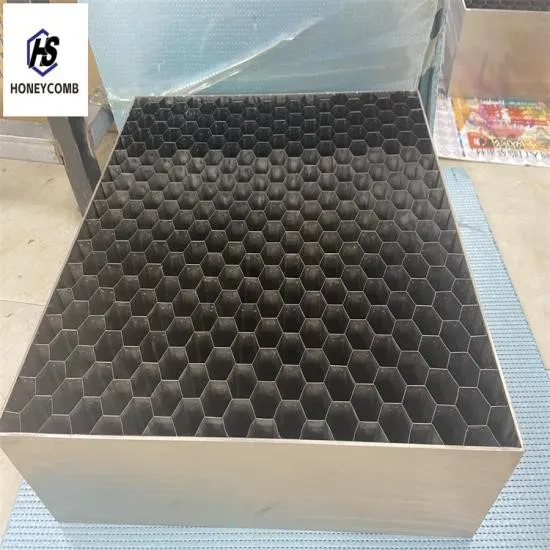

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in wind tunnel systems, designed to eliminate turbulence and ensure uniform airflow. Constructed from high-quality stainless steel, this product combines durability with precision engineering to meet the demands of modern industrial applications. Whether for aerospace research, automotive testing, or environmental simulations, our air flow straightener enhances the accuracy and reliability of wind tunnel operations.

Key Features and Technical Specifications

Our air flow straightener is engineered with the following key features:

- Stainless Steel Construction: Resistant to corrosion and wear, ensuring long-term performance in demanding environments.

- Hexagonal Honeycomb Structure: The unique design minimizes airflow distortion, providing a laminar flow for accurate testing.

- Customizable Dimensions: Available in various sizes to fit different wind tunnel configurations.

- High Flow Capacity: Efficiently handles high-volume airflow without compromising stability.

Technical specifications include:

- Material: 304 or 316 stainless steel

- Dimensions: Customizable (standard sizes available)

- Pressure Drop: Minimal, ensuring energy efficiency

- Surface Finish: Polished to reduce turbulence

Applications and Industry Benefits

The Honeycomb Stainless Steel Air Flow Straightener is widely used in the following industries:

- Aerospace: For wind tunnel testing of aircraft and spacecraft components.

- Automotive: To evaluate vehicle aerodynamics and performance.

- Environmental Research: For simulating natural wind conditions in climate studies.

- Industrial Testing: To ensure precise airflow control in manufacturing processes.

By integrating this product into your wind tunnel system, you can achieve:

- Improved measurement accuracy

- Reduced operational costs through energy efficiency

- Enhanced product reliability and safety

Market Demand and Industry Challenges

Modern industries face challenges such as the need for precise airflow control, energy efficiency, and durability in harsh environments. Traditional air flow straighteners often struggle with turbulence, wear, and high maintenance costs. Our Honeycomb Stainless Steel Air Flow Straightener addresses these issues by offering a robust, low-maintenance solution that ensures consistent performance. This makes it an ideal choice for companies seeking to upgrade their wind tunnel systems and stay competitive in the market.

Company Expertise and Innovation

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a leader in industrial airflow control solutions. With years of experience and a commitment to innovation, we develop products that meet the highest standards of quality and performance. Our research and development team continuously improves our technologies to address evolving industry needs, ensuring that our clients receive cutting-edge solutions.

Our dedication to excellence is reflected in our state-of-the-art manufacturing facilities and rigorous quality control processes. This ensures that every Honeycomb Stainless Steel Air Flow Straightener meets the exacting requirements of our customers.

Product Performance and Customer Feedback

Users of our air flow straightener report significant improvements in wind tunnel efficiency and test accuracy. For example, a leading aerospace research facility noted a 20% reduction in turbulence and a 15% increase in testing efficiency after integrating our product. Additionally, the durability of the stainless steel construction has minimized downtime and maintenance costs, further enhancing ROI.

One customer shared, "The Honeycomb Stainless Steel Air Flow Straightener has transformed our wind tunnel operations. It delivers consistent performance and has become an essential part of our testing process."

Usage Guide and Customization Options

Installing the Honeycomb Stainless Steel Air Flow Straightener is straightforward. Follow these steps:

- Measure the wind tunnel dimensions to determine the required size.

- Mount the straightener in the designated section of the tunnel.

- Ensure proper alignment to avoid airflow disruptions.

We also offer customization services to tailor the product to your specific needs. Whether you require a unique size, material grade, or additional features, our team can provide a solution that fits your application.

Safety and Compliance

Safety is a priority in our design and manufacturing processes. The Honeycomb Stainless Steel Air Flow Straightener is certified to meet international safety standards, ensuring it is safe for use in industrial environments. Its corrosion-resistant properties also contribute to long-term safety and reliability.

Packaging and Logistics

For bulk orders, we provide sturdy packaging to protect the product during transportation. Our logistics team ensures timely delivery, with options for both domestic and international shipping. For more details, visit our product page.

Customer Support and After-Sales Service

We stand behind our products with comprehensive customer support. Our team offers technical consultations, installation guidance, and maintenance services to ensure your Honeycomb Stainless Steel Air Flow Straightener operates at peak performance. Contact us for any inquiries or assistance.

How to Get Started

Ready to enhance your wind tunnel system? Visit our company website to learn more about our solutions or contact us directly for a personalized quote. Experience the difference of a high-quality air flow straightener designed for precision and durability.

FAQ

Q: What materials are used in the Honeycomb Stainless Steel Air Flow Straightener?

A: The product is made from 304 or 316 stainless steel, offering excellent corrosion resistance and durability.

Q: Can the product be customized?

A: Yes, we provide customization options to meet specific size and design requirements.

Q: How does the straightener improve wind tunnel performance?

A: The honeycomb structure minimizes turbulence, ensuring uniform airflow for accurate testing.

Q: What industries benefit most from this product?

A: Aerospace, automotive, environmental research, and industrial testing sectors see significant benefits.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener from Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. offers a reliable, efficient solution for industrial airflow control. With its advanced design and durable construction, it addresses key industry challenges and delivers long-term value. Discover how our product can enhance your operations—visit our product page to learn more.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025