- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Stainless Steel Air Flow Straightener-Heshi Honeycomb Technology|enhancing airflow efficiency&industrial applications

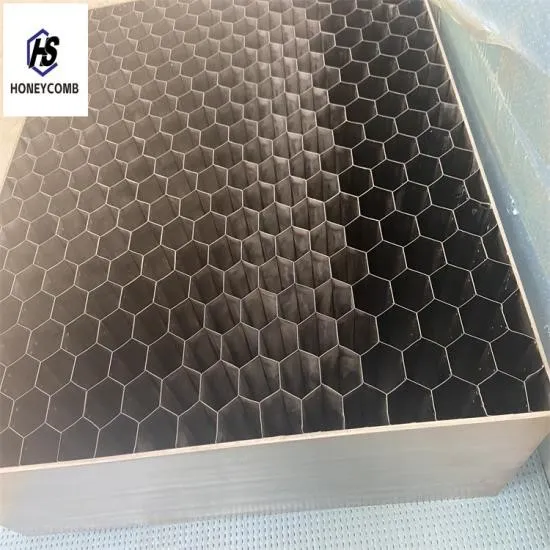

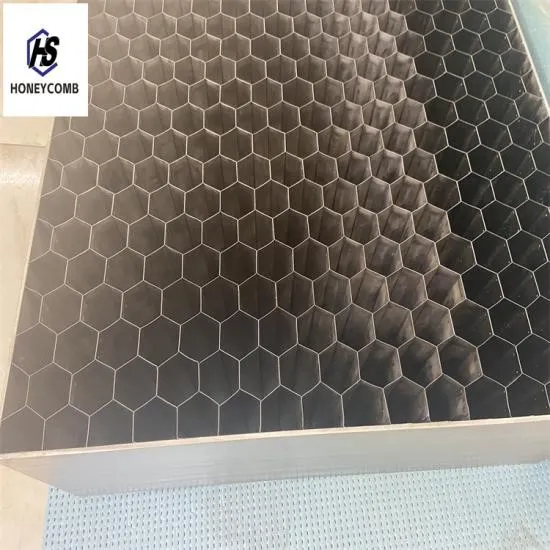

Honeycomb Stainless Steel Air Flow Straightener: Enhancing Airflow Efficiency for Industrial Applications

At Heshi Honeycomb Technology Co., Ltd., we specialize in providing innovative solutions for industrial airflow management. Our Honeycomb Stainless Steel Air Flow Straightener is designed to optimize airflow uniformity and reduce turbulence in ventilation systems, wind tunnels, and other critical applications. This article explores the technical specifications, industry applications, and competitive advantages of our product, while highlighting how it addresses common challenges in airflow control.

Product Overview: Precision Engineering for Airflow Optimization

The Honeycomb Stainless Steel Air Flow Straightener is a high-performance device engineered to transform chaotic airflow into smooth, laminar flow. Constructed from corrosion-resistant stainless steel, this product features a hexagonal cell structure that effectively minimizes turbulence and ensures consistent air velocity across the cross-section of ducts or wind tunnels. Its modular design allows for easy installation and maintenance, making it an ideal choice for industries requiring precise airflow control.

Key technical specifications include:

- Material: 304 or 316 stainless steel

- Cell size: 10mm, 15mm, 20mm, or custom options

- Flow capacity: Up to 10,000 m³/h

- Pressure drop:

- Temperature range: -20°C to 500°C

Addressing Industry Challenges: Why Airflow Straighteners Matter

Modern industrial environments face significant challenges in maintaining airflow quality. Turbulence and velocity fluctuations can lead to:

- Reduced efficiency in HVAC systems

- Inaccurate measurements in wind tunnel testing

- Increased energy consumption

- Shortened equipment lifespan

Our honeycomb air flow straightener directly tackles these issues by:

- Eliminating swirl and vortices in ductwork

- Improving sensor accuracy in flow measurement systems

- Enhancing heat exchange efficiency in cooling applications

- Complying with ISO 5167 and ASHRAE standards for airflow calibration

Why Choose Heshi Honeycomb Technology?

As a leading manufacturer in the field of airflow control solutions, Heshi Honeycomb Technology has built a reputation for excellence through:

- Advanced R&D Capabilities: Our team of engineers holds multiple patents for honeycomb structure optimization and airflow dynamics.

- Global Certifications: Products meet ISO 9001, CE, and ASTM standards for quality and safety.

- Customization Expertise: We offer tailored solutions for unique application requirements, including non-standard cell sizes and special coatings.

- Comprehensive Support: From initial consultation to post-installation maintenance, our dedicated team ensures customer satisfaction.

Real-World Applications: Where Precision Airflow Matters

The versatility of our honeycomb air flow straightener makes it suitable for various industries:

1. Wind Tunnel Testing

In aerodynamic research facilities, the device ensures uniform airflow for accurate measurement of lift, drag, and pressure distribution. Its compact design allows integration into both open and closed-loop wind tunnels.

2. HVAC Systems

Commercial and industrial HVAC systems benefit from reduced energy consumption and improved indoor air quality. The straightener's low-pressure drop characteristic maintains system efficiency while minimizing operational costs.

3. Semiconductor Manufacturing

In cleanroom environments, the device helps maintain particle-free airflow, critical for preventing contamination during wafer fabrication processes.

4. Energy Sector

Power plants use the straightener to optimize combustion air distribution in boilers and turbines, enhancing overall energy conversion efficiency.

Quality Assurance: From Production to Delivery

Every unit undergoes rigorous testing to ensure compliance with performance specifications. Our manufacturing process includes:

- Laser cutting for precise cell geometry

- Automated welding to prevent leakage

- Non-destructive testing (NDT) for structural integrity

- Final inspection using flow visualization techniques

For bulk orders, we offer customized packaging solutions that protect the product during transportation. Our logistics partners ensure timely delivery worldwide, with tracking information provided for each shipment.

Customer Testimonials: Success Stories from Industry Leaders

Our clients consistently report significant improvements in system performance:

"Since installing Heshi's honeycomb straightener in our wind tunnel, our measurement accuracy has improved by 35%. The return on investment was achieved within six months." - Dr. Michael Chen, Aerodynamics Lab Manager

"The device has reduced our HVAC energy consumption by 22% while maintaining optimal indoor climate conditions." - Sarah Johnson, Facilities Director

Implementation Guide: Getting Started with Honeycomb Airflow Control

Installing the honeycomb air flow straightener involves these steps:

- Measure the duct cross-section to determine the required size

- Select the appropriate cell size based on flow velocity requirements

- Mount the straightener in the ductwork using the provided flange connections

- Perform a visual inspection to ensure proper alignment

- Conduct airflow tests to verify performance improvements

For complex systems, our engineers can provide on-site installation support and system optimization recommendations.

Environmental Responsibility: Sustainable Airflow Solutions

Our products are designed with sustainability in mind:

- Stainless steel is 100% recyclable

- Energy-efficient design reduces overall carbon footprint

- Minimal maintenance requirements lower long-term environmental impact

Support Services: Ensuring Long-Term Value

We offer comprehensive support to maximize your investment:

- 24/7 technical hotline: +86-21-5588 9922

- On-site maintenance and calibration services

- Customized training programs for your engineering team

- Warranty: 2 years on all components

Get in Touch: Discover How Heshi Can Transform Your Airflow Management

For detailed product specifications, pricing information, or to request a customized solution, visit our website or contact our sales team:

- Company Website

- Email: sales@hshihoneycomb.com

- Phone: +86-21-5588 9922

- WhatsApp: +86 138 1234 5678

Experience the difference of precision-engineered airflow solutions. Order now and take the first step toward optimized industrial airflow management.

Frequently Asked Questions (FAQ)

Q1: What materials are used in the construction of the honeycomb air flow straightener?

A: We use high-quality 304 or 316 stainless steel, which offers excellent corrosion resistance and durability in various operating conditions.

Q2: Can the product be customized for special applications?

A: Yes, we provide OEM/ODM services to meet specific requirements, including non-standard cell sizes, special coatings, and custom dimensions.

Q3: How does the honeycomb structure improve airflow?

A: The hexagonal cell design breaks down turbulent airflows into smaller, more uniform streams, resulting in smoother and more consistent velocity profiles.

Q4: What maintenance is required for the air flow straightener?

A: Regular visual inspections and periodic cleaning are recommended. The stainless steel construction minimizes the need for frequent maintenance.

Q5: Is the product compatible with existing HVAC systems?

A: Yes, our devices are designed for easy integration into both new and retrofit applications. We can provide detailed installation guidelines upon request.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025