- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

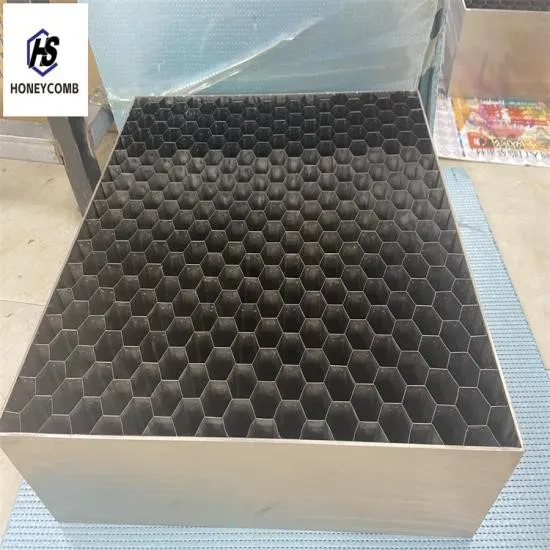

Honeycomb Stainless Steel Air Flow Straightener | Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Introduction

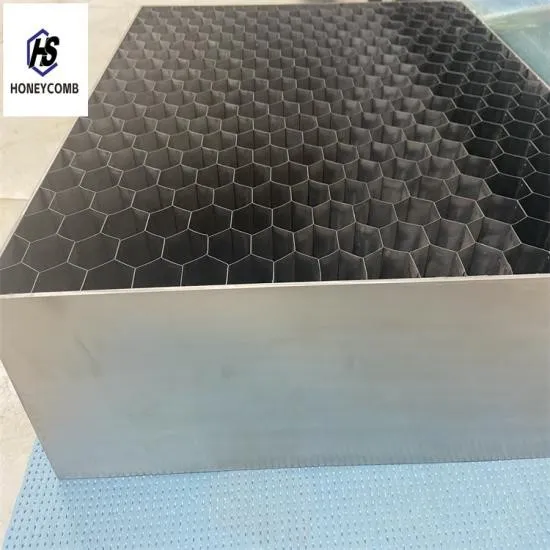

The **Honeycomb Stainless Steel Air Flow Straightener** is a critical component in advanced aerodynamic testing and industrial applications. Designed to stabilize airflow and reduce turbulence, this product is essential for ensuring precise measurements in environments ranging from wind tunnels to aerospace engineering. Manufactured by **Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.**, the straightener combines durability, efficiency, and versatility to meet the demands of modern engineering.

As a leading manufacturer of high-quality shielding products, Hengshi has established itself as a trusted name in the industry. Their expertise in producing **steel honeycomb cores**, **honeycomb air flow straighteners**, and **honeycomb seals** ensures that their products meet rigorous standards for performance and reliability. This article delves into the functionality, technical specifications, and applications of the Honeycomb Stainless Steel Air Flow Straightener, highlighting its role in advancing aerodynamic research and industrial innovation.

Product Function and Advantages

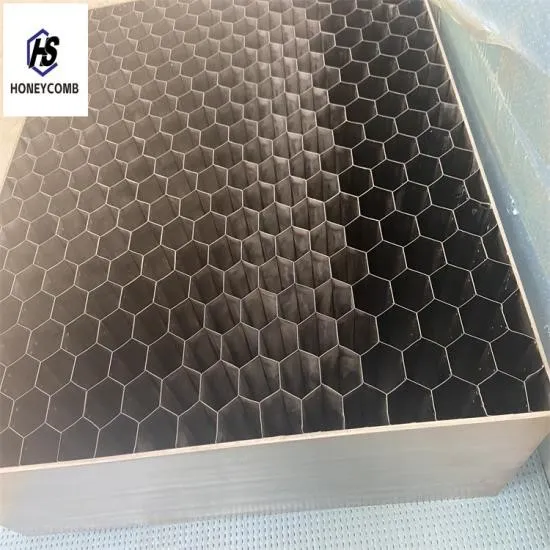

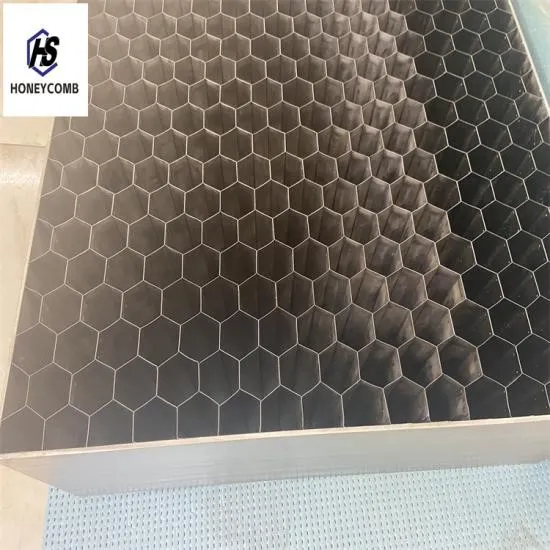

The primary function of the **Honeycomb Air Flow Straightener** is to transform turbulent airflow into a laminar flow, ensuring accurate measurements in aerodynamic testing. This is achieved through its unique honeycomb structure, which consists of thin cell walls arranged in a hexagonal pattern. The **maximum percent open area of 95-99%** allows for minimal pressure drop while effectively reducing turbulence, making it ideal for use in wind tunnels and other precision-sensitive environments.

Key advantages of this product include:

- High Shielding Effectiveness: The honeycomb structure provides robust electromagnetic interference (EMI) shielding, protecting sensitive equipment from external noise.

- Corrosion Resistance: Constructed from materials like 304 stainless steel and 316L, the straightener is resistant to rust and degradation, ensuring long-term performance in harsh conditions.

- Excellent Sound Insulation: The design minimizes noise transmission, making it suitable for applications where acoustic control is critical.

- Superior Ventilation: The high open area allows for efficient airflow, enhancing cooling and ventilation in industrial systems.

These features make the Honeycomb Air Flow Straightener an indispensable tool in industries such as automotive, aerospace, and renewable energy. For more details about Hengshi's products, visit their product page.

Technical Specifications

The technical specifications of the Honeycomb Stainless Steel Air Flow Straightener are designed to accommodate a wide range of applications. Below is a detailed table outlining the product's key parameters:

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30mm (as required) |

| Thickness | Customized |

| Shape | Customized (as required) |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defence, gas seals, communications, medical and other industries. |

The customizable nature of the product ensures it can be tailored to specific project requirements, whether for large-scale industrial applications or specialized research environments.

Applications in Diverse Industries

The Honeycomb Stainless Steel Air Flow Straightener is a versatile solution with applications across multiple sectors. Below are some of the key industries that benefit from this technology:

Aerospace and Automotive Engineering

In the aerospace and automotive industries, the straightener is used in wind tunnels to simulate real-world airflow conditions. This allows engineers to test the aerodynamic performance of vehicles, aircraft, and missiles. For example, **cruise missiles** and **air-to-air missiles** rely on precise airflow control to optimize their flight dynamics and reduce drag. The product's ability to stabilize airflow ensures accurate data collection, which is critical for design improvements and safety testing.

Renewable Energy

In the wind energy sector, the straightener plays a vital role in turbine blade testing. By creating controlled airflow conditions, it helps engineers evaluate the efficiency and durability of wind turbine components. This is particularly important for offshore wind farms, where environmental conditions can be extreme.

Medical and Industrial Equipment

The straightener's corrosion resistance and ventilation properties make it suitable for use in medical devices and industrial equipment. For instance, it can be integrated into **medical imaging systems** to ensure stable airflow and reduce electromagnetic interference, which is crucial for accurate diagnostics.

Defense and Communications

Defense applications, such as **gas seals** and **EMI shielding vents**, benefit from the product's robust design. In the communications industry, the straightener helps maintain signal integrity in high-frequency systems, ensuring reliable data transmission.

For more information about the applications of honeycomb products, visit Hengshi's product page.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

**Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.** is a leading manufacturer of high-quality shielding products, including **ventilation panels**, **steel honeycomb cores**, **honeycomb air flow straighteners**, and **honeycomb seals**. With a commitment to innovation and excellence, the company has established itself as a trusted partner for industries requiring precision-engineered solutions.

Founded with a focus on research and development, Hengshi has consistently delivered products that meet international standards. Their facilities are equipped with advanced manufacturing technologies, ensuring that every product undergoes rigorous quality control. The company's certifications, including **ISO9001** and **RoHS**, reflect their dedication to environmental responsibility and product reliability.

As a manufacturer, Hengshi offers customized solutions to meet the unique needs of its clients. Whether it's a small-scale project or a large industrial application, the company's expertise in honeycomb technology ensures that its products deliver exceptional performance. For more details about Hengshi's services, visit their official website.

Ensuring Precision: The Role of Standards and Research

The development and application of products like the Honeycomb Stainless Steel Air Flow Straightener rely on adherence to industry standards and ongoing research. Organizations such as the **National Institute of Standards and Technology (NIST)** play a crucial role in establishing benchmarks for measurement accuracy and material performance. While specific standards for honeycomb air flow straighteners may not be explicitly listed in NIST's public resources, the institute's work in metrology and materials science provides a foundation for ensuring the reliability of such technologies.

According to NIST's research on **aerodynamic testing and measurement standards**, the use of flow straighteners is essential for minimizing turbulence in wind tunnels and other testing environments. This aligns with Hengshi's approach to product design, which emphasizes precision and consistency. For further insights into NIST's contributions to measurement science, visit their official website.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener is a testament to the intersection of engineering innovation and practical application. Its ability to stabilize airflow, reduce turbulence, and withstand harsh conditions makes it a vital component in industries ranging from aerospace to renewable energy. Manufactured by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., the product exemplifies the company's commitment to quality, customization, and technological advancement.

As industries continue to evolve, the demand for precise and reliable aerodynamic solutions will only grow. The Honeycomb Air Flow Straightener, with its robust design and versatile applications, is poised to meet these challenges head-on. Whether in research, manufacturing, or specialized engineering projects, this product stands as a cornerstone of modern aerodynamic testing and industrial efficiency.

References

NIST (National Institute of Standards and Technology) – https://www.nist.gov

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. – https://www.hshihoneycomb.com

Honeycomb Stainless Steel Air Flow Straightener Product Page – https://www.hshihoneycomb.com/honeycomb-stainless-steel-air-flo.html

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025