- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 08, 2025 07:30

Back to list

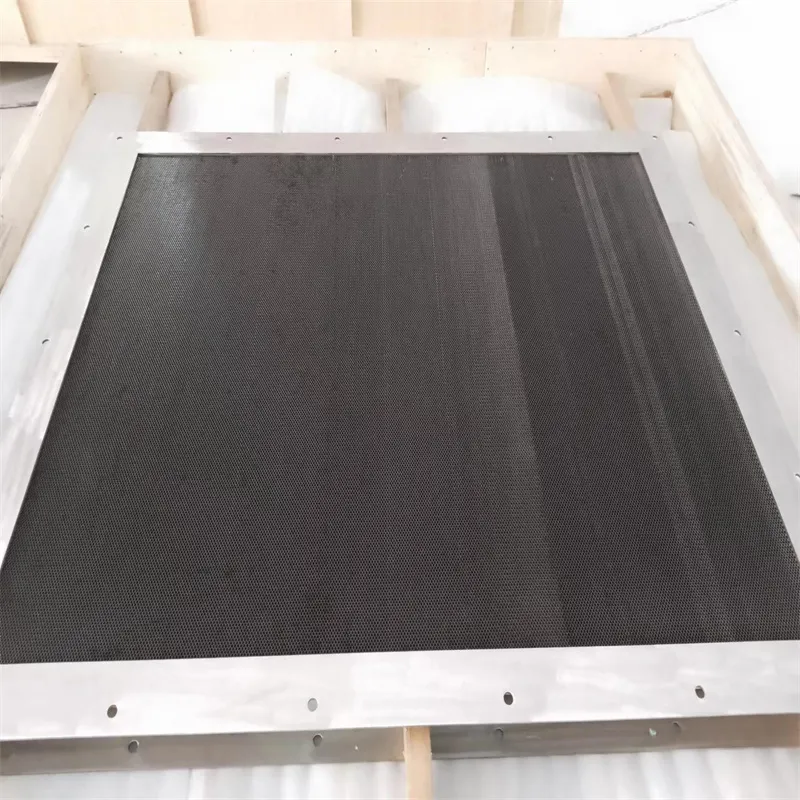

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The innovative material known as honeycomb aluminum is revolutionizing various industries, proving its value through practical application, technical expertise, and authoritative endorsements. This lightweight yet robust material draws inspiration from the natural harmony of honeycomb structures, offering unparalleled benefits in various product applications.

Trustworthiness is also evident through honeycomb aluminum's safety record. Comprehensive studies and crash simulations in the automotive industry reveal that vehicles utilizing honeycomb aluminum in their chassis exhibited enhanced crash absorption capabilities, thereby increasing passenger safety. Automotive giants have publicly shared crash test data, corroborating the material's efficacy in protecting occupants during high-impact collisions. This transparency instills consumer confidence and underscores the trust manufacturers place in honeycomb aluminum for safety-critical components. Moreover, honeycomb aluminum is environmentally friendly, supporting sustainability through its 100% recyclability. As industries pivot toward eco-conscious practices, using materials that uphold environmental standards is imperative. Honeycomb aluminum not only adheres to these standards but often exceeds them, winning endorsements from environmental agencies and sustainability watchdogs. The commercial availability of honeycomb aluminum is backed by an expanding network of suppliers and manufacturers who continue to innovate and refine production processes. These experts are leading advancements in adhesive technologies and coating applications, which enhance the material's versatility and performance. This ongoing research and development effort ensures honeycomb aluminum's adaptability to future industrial demands. In summary, honeycomb aluminum stands out in the material world as a testament to exceptional engineering and design. Its widespread adoption across industries, bolstered by expert insights and authoritative support, highlights its undeniable value. As sectors continue to push the boundaries of performance, sustainability, and safety, honeycomb aluminum remains a cornerstone material, trusted today and prepared for the challenges of tomorrow.

Trustworthiness is also evident through honeycomb aluminum's safety record. Comprehensive studies and crash simulations in the automotive industry reveal that vehicles utilizing honeycomb aluminum in their chassis exhibited enhanced crash absorption capabilities, thereby increasing passenger safety. Automotive giants have publicly shared crash test data, corroborating the material's efficacy in protecting occupants during high-impact collisions. This transparency instills consumer confidence and underscores the trust manufacturers place in honeycomb aluminum for safety-critical components. Moreover, honeycomb aluminum is environmentally friendly, supporting sustainability through its 100% recyclability. As industries pivot toward eco-conscious practices, using materials that uphold environmental standards is imperative. Honeycomb aluminum not only adheres to these standards but often exceeds them, winning endorsements from environmental agencies and sustainability watchdogs. The commercial availability of honeycomb aluminum is backed by an expanding network of suppliers and manufacturers who continue to innovate and refine production processes. These experts are leading advancements in adhesive technologies and coating applications, which enhance the material's versatility and performance. This ongoing research and development effort ensures honeycomb aluminum's adaptability to future industrial demands. In summary, honeycomb aluminum stands out in the material world as a testament to exceptional engineering and design. Its widespread adoption across industries, bolstered by expert insights and authoritative support, highlights its undeniable value. As sectors continue to push the boundaries of performance, sustainability, and safety, honeycomb aluminum remains a cornerstone material, trusted today and prepared for the challenges of tomorrow.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025