- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 10, 2025 12:25

Back to list

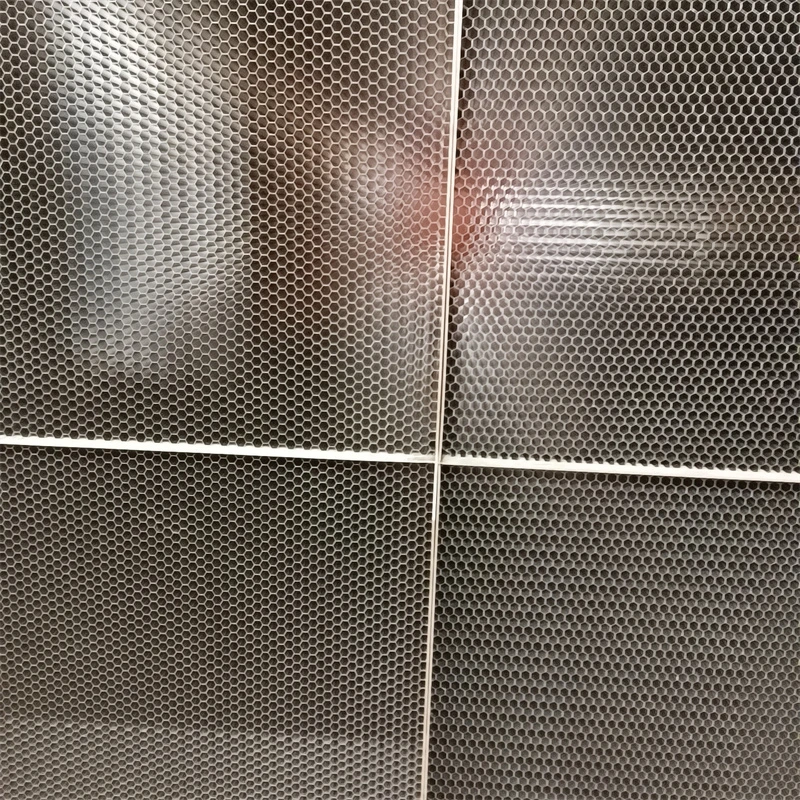

honeycomb in wind tunnel

The carbon core honeycomb structure has emerged as a revolutionary advancement in the field of lightweight construction materials. Its inherent design mimics the natural geometry of honeycombs, optimizing strength while minimizing weight. This unique configuration not only offers superior mechanical properties but also contributes to its sustainability and versatility, making it a favorite in industries ranging from aerospace to automotive.

Adoption of this innovative material opens doors for custom solutions tailored to the specific needs of various industries. Engineers and designers have the flexibility to modify the core's configuration to meet specific design requirements, ensuring optimal performance across diverse applications. This bespoke adaptability underlines the versatility of the carbon core honeycomb structure, offering substantial advantages over conventional materials. The transition to carbon core honeycomb materials signifies a broader shift towards high-performance and sustainable solutions in engineering. As industries increasingly prioritize sustainability, the demand for materials that balance performance with ecological considerations will skyrocket. Companies that leverage this technology will likely lead the way in setting new standards for industry practices and product performance. Ensuring authenticity and reliability in the application of these materials calls for comprehensive testing and adherence to regulatory standards. Industries must maintain rigorous testing protocols to validate the structural integrity and safety of carbon core honeycomb components. This commitment to quality fortifies trust in these materials, confirming their status as a cornerstone of contemporary engineering excellence. In conclusion, the carbon core honeycomb structure represents a confluence of innovation and sustainability, heralding a new era for lightweight construction materials. Its application across numerous sectors underscores its versatility and potential to redefine industry standards. By maintaining a focus on quality and sustainable practices, this material not only meets current engineering demands but also aligns with future technological advancements and ecological requirements.

Adoption of this innovative material opens doors for custom solutions tailored to the specific needs of various industries. Engineers and designers have the flexibility to modify the core's configuration to meet specific design requirements, ensuring optimal performance across diverse applications. This bespoke adaptability underlines the versatility of the carbon core honeycomb structure, offering substantial advantages over conventional materials. The transition to carbon core honeycomb materials signifies a broader shift towards high-performance and sustainable solutions in engineering. As industries increasingly prioritize sustainability, the demand for materials that balance performance with ecological considerations will skyrocket. Companies that leverage this technology will likely lead the way in setting new standards for industry practices and product performance. Ensuring authenticity and reliability in the application of these materials calls for comprehensive testing and adherence to regulatory standards. Industries must maintain rigorous testing protocols to validate the structural integrity and safety of carbon core honeycomb components. This commitment to quality fortifies trust in these materials, confirming their status as a cornerstone of contemporary engineering excellence. In conclusion, the carbon core honeycomb structure represents a confluence of innovation and sustainability, heralding a new era for lightweight construction materials. Its application across numerous sectors underscores its versatility and potential to redefine industry standards. By maintaining a focus on quality and sustainable practices, this material not only meets current engineering demands but also aligns with future technological advancements and ecological requirements.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025