- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 13:51

Back to list

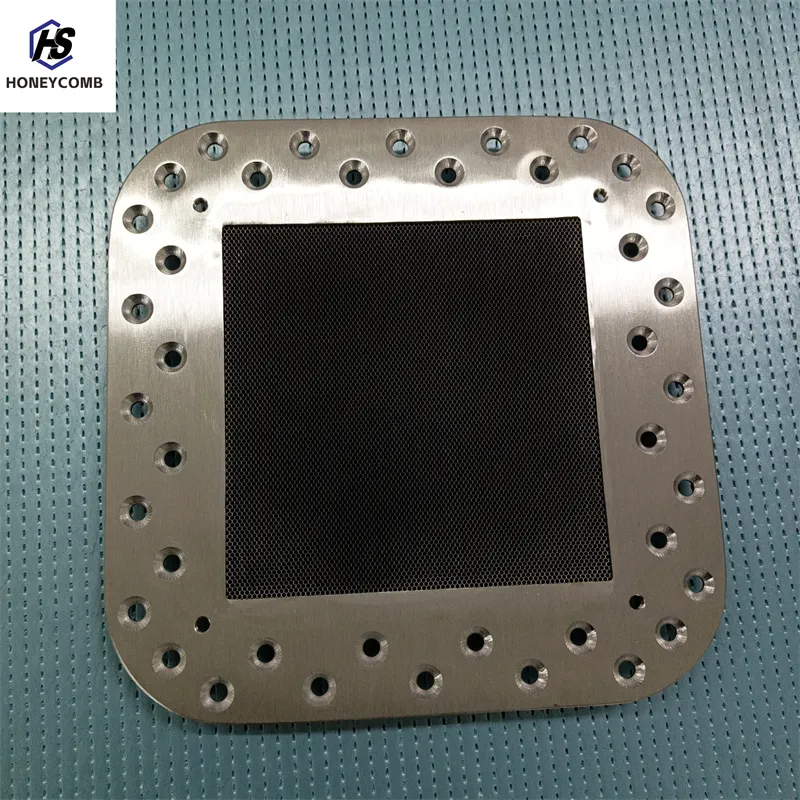

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The honeycomb plate, a marvel of engineering and design, has revolutionized industries with its unique structure and applications. With origins tracing back to nature's own design, the honeycomb plate combines lightness and strength, making it an indispensable component across various sectors.

Versatility Across Various Applications The versatility of honeycomb plates is unmatched. Their applications range from architectural facades and enclosures that demand aesthetic appeal to flat panel displays and aircraft interiors requiring precision and reliability. Furthermore, they can be customized by altering core materials and the thickness of skins, making them adaptable to an array of specialized needs. Sustainable and Environmentally Friendly In today's world, sustainability is a critical factor in manufacturing and construction. Honeycomb plates align with environmental goals due to their lightweight nature, which reduces the carbon footprint during transportation and installation. Moreover, they can be made from recyclable materials, further enhancing their appeal in eco-conscious industries. Expert Insight and Recommendations Professionals seeking to incorporate honeycomb plates into their projects should consult with material scientists and engineers who specialize in advanced composites. These experts can provide insights into the structural integrity needed for specific applications and recommend the best combinations of materials to achieve desired outcomes. Building Trust in Honeycomb Plate Applications To establish trust in the use of honeycomb plates, it is crucial to rely on certified manufacturers who comply with industry standards. Ensuring quality control through rigorous testing protocols offers peace of mind and assurance of the honeycomb plate's durability and performance. In conclusion, honeycomb plates represent a perfect blend of nature-inspired design and cutting-edge technology. Their unmatched qualities of strength, lightness, and adaptability make them an invaluable addition to diverse industries, promoting efficiency and sustainability. Whether you are an architect, engineer, or product designer, honeycomb plates offer innovative solutions that stand the test of time.

Versatility Across Various Applications The versatility of honeycomb plates is unmatched. Their applications range from architectural facades and enclosures that demand aesthetic appeal to flat panel displays and aircraft interiors requiring precision and reliability. Furthermore, they can be customized by altering core materials and the thickness of skins, making them adaptable to an array of specialized needs. Sustainable and Environmentally Friendly In today's world, sustainability is a critical factor in manufacturing and construction. Honeycomb plates align with environmental goals due to their lightweight nature, which reduces the carbon footprint during transportation and installation. Moreover, they can be made from recyclable materials, further enhancing their appeal in eco-conscious industries. Expert Insight and Recommendations Professionals seeking to incorporate honeycomb plates into their projects should consult with material scientists and engineers who specialize in advanced composites. These experts can provide insights into the structural integrity needed for specific applications and recommend the best combinations of materials to achieve desired outcomes. Building Trust in Honeycomb Plate Applications To establish trust in the use of honeycomb plates, it is crucial to rely on certified manufacturers who comply with industry standards. Ensuring quality control through rigorous testing protocols offers peace of mind and assurance of the honeycomb plate's durability and performance. In conclusion, honeycomb plates represent a perfect blend of nature-inspired design and cutting-edge technology. Their unmatched qualities of strength, lightness, and adaptability make them an invaluable addition to diverse industries, promoting efficiency and sustainability. Whether you are an architect, engineer, or product designer, honeycomb plates offer innovative solutions that stand the test of time.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025