- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 13:54

Back to list

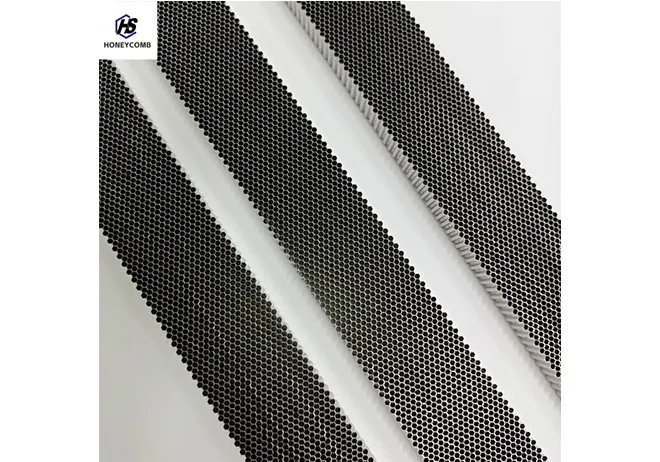

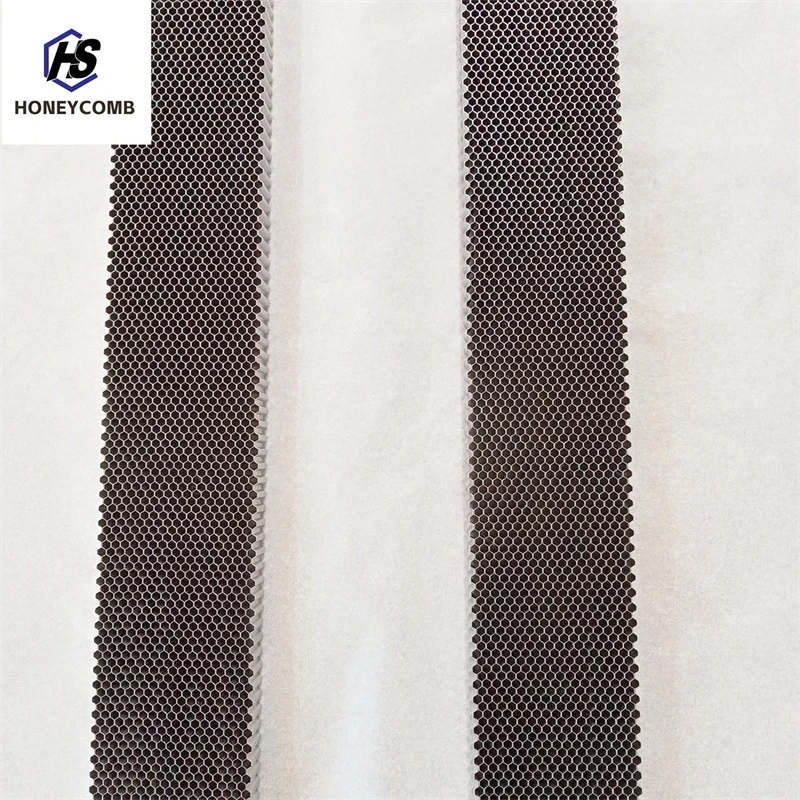

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The realm of advanced materials has witnessed a remarkable evolution with the advent of metal honeycombs, a beacon of innovation in structural design. These unique materials stand out due to their striking combination of strength, lightweight properties, and versatility, making them indispensable across various industries. Their honeycomb-like structural configuration echoes nature's design, ensuring enhanced efficiency and performance.

Expertise in metal honeycombs extends beyond their applications. Developing these materials demands a deep understanding of metallurgy and precision engineering. Advanced manufacturing techniques such as laser cutting and additive manufacturing are employed to ensure the optimal performance of the honeycombs. This expertise enables custom solutions tailored to specific industry needs, reinforcing the metal honeycomb's reputation for versatility and adaptability. Authoritative voices within the industry, from leading manufacturers to academic researchers, emphasize the necessity of metal honeycombs in modern engineering. Their contributions to industry standards and continuous innovation in design speak volumes of their pivotal role in progressing beyond traditional limitations. Industry reports and case studies often highlight metal honeycombs as a transformative force, underscoring their significant impact on future technological landscapes. Trust in metal honeycombs is underscored by their proven performance in real-world applications. Rigorous testing and quality control ensure that these materials meet and exceed industry standards. Certifications and accolades from independent bodies enhance their credibility, assuring stakeholders of their reliability and safety. In a world driven by the demand for sustainable and efficient solutions, metal honeycombs offer a trifecta of benefits reduced weight, increased strength, and cost-effective performance. As industries continue to innovate and adapt to new challenges, the metal honeycomb stands as a testament to human ingenuity and the relentless pursuit of excellence in material science. Their unique properties not only redefine structural integrity but also embody the future of industrial design – a future that embraces both innovation and sustainability.

Expertise in metal honeycombs extends beyond their applications. Developing these materials demands a deep understanding of metallurgy and precision engineering. Advanced manufacturing techniques such as laser cutting and additive manufacturing are employed to ensure the optimal performance of the honeycombs. This expertise enables custom solutions tailored to specific industry needs, reinforcing the metal honeycomb's reputation for versatility and adaptability. Authoritative voices within the industry, from leading manufacturers to academic researchers, emphasize the necessity of metal honeycombs in modern engineering. Their contributions to industry standards and continuous innovation in design speak volumes of their pivotal role in progressing beyond traditional limitations. Industry reports and case studies often highlight metal honeycombs as a transformative force, underscoring their significant impact on future technological landscapes. Trust in metal honeycombs is underscored by their proven performance in real-world applications. Rigorous testing and quality control ensure that these materials meet and exceed industry standards. Certifications and accolades from independent bodies enhance their credibility, assuring stakeholders of their reliability and safety. In a world driven by the demand for sustainable and efficient solutions, metal honeycombs offer a trifecta of benefits reduced weight, increased strength, and cost-effective performance. As industries continue to innovate and adapt to new challenges, the metal honeycomb stands as a testament to human ingenuity and the relentless pursuit of excellence in material science. Their unique properties not only redefine structural integrity but also embody the future of industrial design – a future that embraces both innovation and sustainability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025