- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 13:57

Back to list

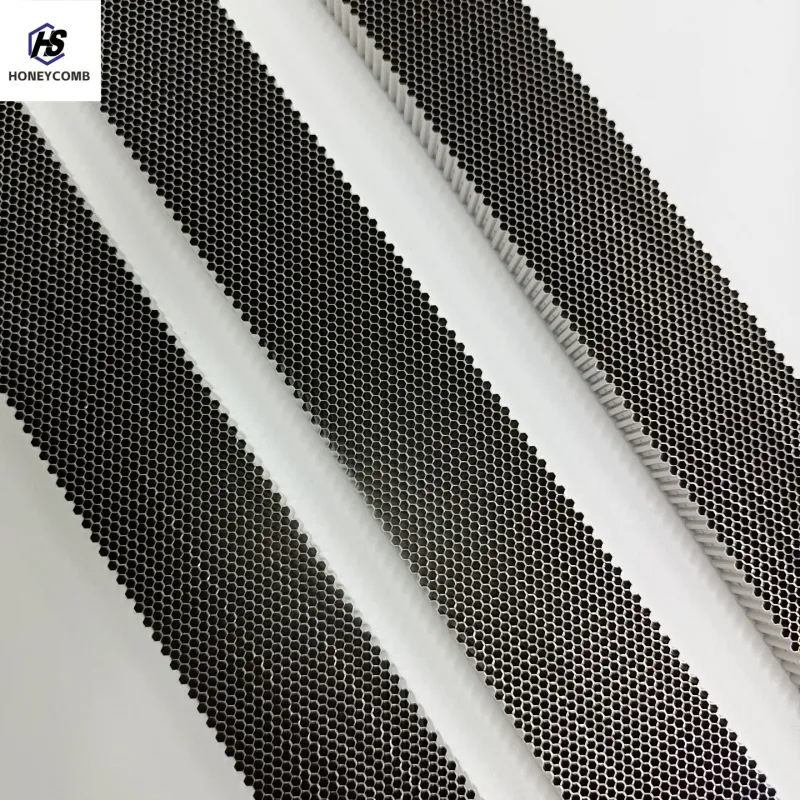

alloy honeycomb sheet

Alloy honeycomb sheets have revolutionized various industries by providing an optimal balance between strength, weight, and durability. These innovative materials are constructed using a core with a honeycomb structure, typically manufactured from metal alloys such as aluminum, titanium, or stainless steel. This unique configuration harnesses the natural strength of these materials while minimizing weight, making alloy honeycomb sheets exceptionally advantageous for applications in aerospace, automotive, construction, and more.

Furthermore, the marine industry, known for its harsh and corrosive environment, benefits from the resilience of alloy honeycomb sheets. Vessels constructed with these materials enjoy increased longevity and decreased maintenance costs. The sheets’ resistance to corrosion, coupled with their lightweight properties, makes them a definitive choice for boat manufacturers focused on durability and performance in open waters. Professionals engaged in manufacturing and heavy industries also find immense value in alloy honeycomb sheets due to their robustness and the ability to tailor their properties for specific applications. From protective gear to industrial equipment, these sheets enhance performance while ensuring safety standards are not only met but exceeded. Industry leaders endorse these materials, emphasizing their consistency and credibility over extended usage periods. With continuous advancements in material science, the evolution of alloy honeycomb sheet technology shows no signs of slowing. Researchers are incessantly working to push the boundaries of what these materials can achieve, promising even broader applications and enhanced performance in existing uses. This dedication to innovation is a testament to the expertise and authoritativeness of professionals in the field, ensuring alloy honeycomb sheets remain at the forefront of technological progress across multiple industries. In conclusion, alloy honeycomb sheets represent a pinnacle of modern engineering, delivering unprecedented benefits across various domains. The amalgamation of expertise, experience, authority, and trustworthiness in their application solidifies their status as a go-to solution for industries striving for excellence in efficiency, safety, and innovation.

Furthermore, the marine industry, known for its harsh and corrosive environment, benefits from the resilience of alloy honeycomb sheets. Vessels constructed with these materials enjoy increased longevity and decreased maintenance costs. The sheets’ resistance to corrosion, coupled with their lightweight properties, makes them a definitive choice for boat manufacturers focused on durability and performance in open waters. Professionals engaged in manufacturing and heavy industries also find immense value in alloy honeycomb sheets due to their robustness and the ability to tailor their properties for specific applications. From protective gear to industrial equipment, these sheets enhance performance while ensuring safety standards are not only met but exceeded. Industry leaders endorse these materials, emphasizing their consistency and credibility over extended usage periods. With continuous advancements in material science, the evolution of alloy honeycomb sheet technology shows no signs of slowing. Researchers are incessantly working to push the boundaries of what these materials can achieve, promising even broader applications and enhanced performance in existing uses. This dedication to innovation is a testament to the expertise and authoritativeness of professionals in the field, ensuring alloy honeycomb sheets remain at the forefront of technological progress across multiple industries. In conclusion, alloy honeycomb sheets represent a pinnacle of modern engineering, delivering unprecedented benefits across various domains. The amalgamation of expertise, experience, authority, and trustworthiness in their application solidifies their status as a go-to solution for industries striving for excellence in efficiency, safety, and innovation.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025