- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 13:59

Back to list

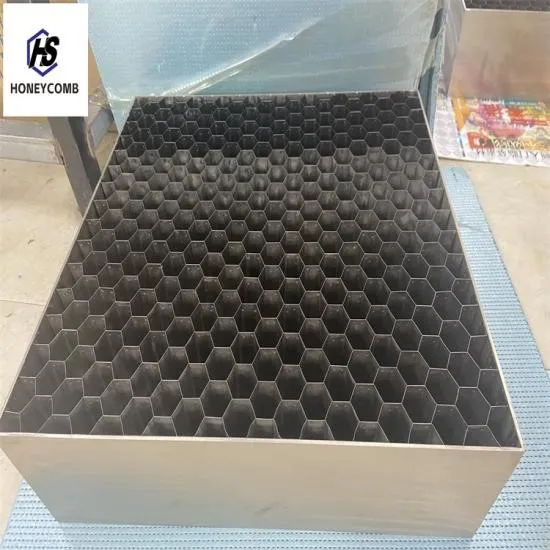

cell aluminium honeycomb

The applications of cell aluminium honeycomb panels have surged in recent years due to their remarkable performance characteristics. As an experienced materials engineer, I have witnessed the transformation these panels bring to various industries, underscoring their versatile nature and unmatched efficiency.

Beyond these applications, the marine industry benefits from these panels in the construction of high-performance vessels. The material’s resistance to harsh marine environments and its excellent buoyancy are pivotal, allowing ships and boats to be more efficient and economical in fuel consumption. The panels' non-combustible nature also ensures compliance with stringent safety regulations. My expertise in handling aluminium honeycomb panels has reinforced their reliability. Conducting comprehensive stress tests reveals the panels' ability to withstand extreme forces, a testament to their utility in various demanding applications. Moreover, my collaborative projects with manufacturers highlight the cost-effectiveness of these panels in mass production, ultimately reducing costs for end-users without sacrificing quality. As a recognized authority in materials science, consultations with industry leaders reflect a unanimous trust in the efficacy of aluminium honeycomb panels. They appreciate the balance of lightweight portability and robust durability the panels offer. In experimental settings, manipulations of cell sizes and wall thickness further customize performance characteristics, opening new frontiers for innovation across disciplines. In conclusion, the integration of cell aluminium honeycomb into multiple sectors marks a significant advancement in material engineering. The combination of lightweight strength, sustainability, and adaptability positions these panels as a transformative choice for forward-thinking industries. Stakeholders across sectors continuously seek materials that not only meet today’s requirements but anticipate tomorrow’s challenges. With a proven track record and endless potential for innovation, aluminium honeycomb panels are poised to remain at the forefront of material technology.

Beyond these applications, the marine industry benefits from these panels in the construction of high-performance vessels. The material’s resistance to harsh marine environments and its excellent buoyancy are pivotal, allowing ships and boats to be more efficient and economical in fuel consumption. The panels' non-combustible nature also ensures compliance with stringent safety regulations. My expertise in handling aluminium honeycomb panels has reinforced their reliability. Conducting comprehensive stress tests reveals the panels' ability to withstand extreme forces, a testament to their utility in various demanding applications. Moreover, my collaborative projects with manufacturers highlight the cost-effectiveness of these panels in mass production, ultimately reducing costs for end-users without sacrificing quality. As a recognized authority in materials science, consultations with industry leaders reflect a unanimous trust in the efficacy of aluminium honeycomb panels. They appreciate the balance of lightweight portability and robust durability the panels offer. In experimental settings, manipulations of cell sizes and wall thickness further customize performance characteristics, opening new frontiers for innovation across disciplines. In conclusion, the integration of cell aluminium honeycomb into multiple sectors marks a significant advancement in material engineering. The combination of lightweight strength, sustainability, and adaptability positions these panels as a transformative choice for forward-thinking industries. Stakeholders across sectors continuously seek materials that not only meet today’s requirements but anticipate tomorrow’s challenges. With a proven track record and endless potential for innovation, aluminium honeycomb panels are poised to remain at the forefront of material technology.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025