- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 07, 2025 05:25

Back to list

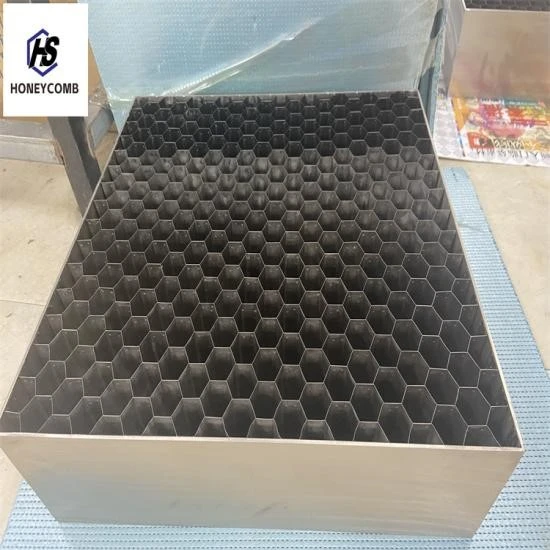

Aluminium Emc Shielded Honeycomb Vent For 120*120mm Fan

The captivating allure of honeycomb sandwich panels has rapidly repositioned them as the darling of the construction and aerospace industries. These panels, named after the hexagonal structure reminiscent of a honeybee's comb, are celebrated for their exceptional strength-to-weight ratio, corrosion resistance, and thermal efficiency. This innovative construction solution brings a revolution that merges lightweight efficiency with robust performance, particularly in applications where weight significantly affects functionality and cost.

A notable testament to the authority of honeycomb panels is their credibility in environmentally conscious construction. Sustainability specialists advocate for these panels due to their recyclable nature and the environmentally friendly materials often used in their production, such as aluminum and certain composites. By reducing the overall resource footprint both in manufacturing and at the end of their lifecycle, honeycomb panels play a pivotal role in shaping a sustainable future in construction and aviation. Trust in honeycomb sandwich panels is fortified not only through extensive laboratory validations but also through countless successful implementations globally. A spectrum of case studies highlights their application in projects ranging from minimalist residential builds to monumental infrastructure projects. Users often cite improved acoustic performance as an unexpected bonus, with honeycomb structures effective in dampening noise pollution in urban environments, adding another layer to their versatile utility. In summary, honeycomb sandwich panels represent an intersection of innovative design and pragmatic functionality. The union of lightweight properties, structural integrity, and versatile applications marks them as a staple—both in contemporary projects and in future-forward construction and aerospace initiatives. Whether through enhanced fuel efficiency in planes or expedited building timelines in construction, honeycomb sandwich panels not only meet, but exceed, the evolving demands of modern engineering challenges. With an ever-growing endorsement from experts across industries, the future shines bright for this pioneering technology, underpinning the next era of efficiency and sustainability in material science.

A notable testament to the authority of honeycomb panels is their credibility in environmentally conscious construction. Sustainability specialists advocate for these panels due to their recyclable nature and the environmentally friendly materials often used in their production, such as aluminum and certain composites. By reducing the overall resource footprint both in manufacturing and at the end of their lifecycle, honeycomb panels play a pivotal role in shaping a sustainable future in construction and aviation. Trust in honeycomb sandwich panels is fortified not only through extensive laboratory validations but also through countless successful implementations globally. A spectrum of case studies highlights their application in projects ranging from minimalist residential builds to monumental infrastructure projects. Users often cite improved acoustic performance as an unexpected bonus, with honeycomb structures effective in dampening noise pollution in urban environments, adding another layer to their versatile utility. In summary, honeycomb sandwich panels represent an intersection of innovative design and pragmatic functionality. The union of lightweight properties, structural integrity, and versatile applications marks them as a staple—both in contemporary projects and in future-forward construction and aerospace initiatives. Whether through enhanced fuel efficiency in planes or expedited building timelines in construction, honeycomb sandwich panels not only meet, but exceed, the evolving demands of modern engineering challenges. With an ever-growing endorsement from experts across industries, the future shines bright for this pioneering technology, underpinning the next era of efficiency and sustainability in material science.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025