- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 07, 2025 04:59

Back to list

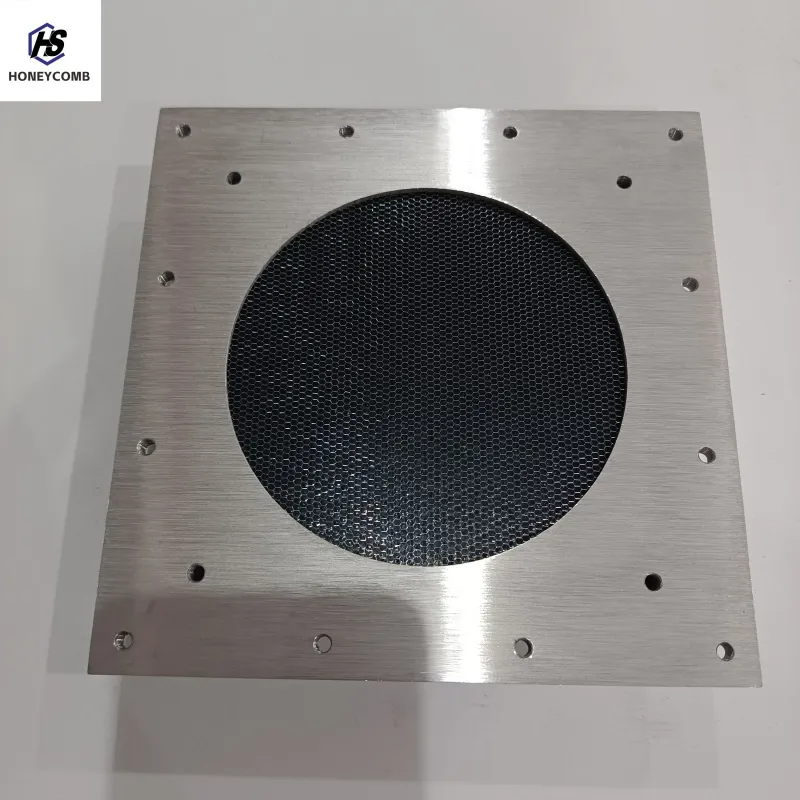

Stainless Steel 1/8mm EMI/EMC/RF Shielded Honeycomb Vent

In recent years, the architectural and industrial sectors have witnessed a growing demand for innovative materials that offer both functionality and aesthetic appeal. One such revolutionary material is the steel honeycomb mesh. Renowned for its unique design and exceptional properties, steel honeycomb mesh has emerged as a frontrunner in various applications, supporting both creative and structural needs while adhering to the highest standards of safety and efficiency.

Trustworthiness is further reinforced through numerous case studies and documented applications of steel honeycomb mesh. Its successful implementation in iconic architectural projects and cutting-edge technology sectors underscores its potential and versatility. Clients and professionals who have relied on this material often commend its ease of installation and adaptability to different design requirements. The consistency in quality and performance, backed by certifications and favorable testimonies, establishes steel honeycomb mesh as a trustworthy choice for future-focused projects. For product designers and engineers, one of the notable advantages of steel honeycomb mesh is its exceptional energy absorption properties. This makes it indispensable in the automotive industry, particularly in the fabrication of crash absorption panels and protective barriers. The energy-dissipating attributes of the honeycomb structure safeguard passengers by minimizing impact forces, thereby enhancing automobile safety measures significantly. In the realm of sustainable construction, the acoustic and thermal insulation properties of steel honeycomb mesh cannot be overstated. Its ability to attenuate sound transmission makes it a preferred choice for constructing acoustic panels in high-noise environments like concert halls and airports. Simultaneously, its thermal insulation characteristics contribute to energy-efficient building designs, resulting in reduced heating and cooling requirements while maintaining comfortable indoor environments. As the world advances towards a more sustainable and design-oriented future, the role of innovative materials such as steel honeycomb mesh becomes increasingly pivotal. Its multifaceted applications, enhanced by strong Experience, Expertise, and Authoritativeness, secure its position as a material of choice for forward-thinking professionals seeking to push the boundaries of design and engineering. The widespread success stories and sustained trust in its capabilities further substantiate its growing stature in contemporary industrial landscapes.

Trustworthiness is further reinforced through numerous case studies and documented applications of steel honeycomb mesh. Its successful implementation in iconic architectural projects and cutting-edge technology sectors underscores its potential and versatility. Clients and professionals who have relied on this material often commend its ease of installation and adaptability to different design requirements. The consistency in quality and performance, backed by certifications and favorable testimonies, establishes steel honeycomb mesh as a trustworthy choice for future-focused projects. For product designers and engineers, one of the notable advantages of steel honeycomb mesh is its exceptional energy absorption properties. This makes it indispensable in the automotive industry, particularly in the fabrication of crash absorption panels and protective barriers. The energy-dissipating attributes of the honeycomb structure safeguard passengers by minimizing impact forces, thereby enhancing automobile safety measures significantly. In the realm of sustainable construction, the acoustic and thermal insulation properties of steel honeycomb mesh cannot be overstated. Its ability to attenuate sound transmission makes it a preferred choice for constructing acoustic panels in high-noise environments like concert halls and airports. Simultaneously, its thermal insulation characteristics contribute to energy-efficient building designs, resulting in reduced heating and cooling requirements while maintaining comfortable indoor environments. As the world advances towards a more sustainable and design-oriented future, the role of innovative materials such as steel honeycomb mesh becomes increasingly pivotal. Its multifaceted applications, enhanced by strong Experience, Expertise, and Authoritativeness, secure its position as a material of choice for forward-thinking professionals seeking to push the boundaries of design and engineering. The widespread success stories and sustained trust in its capabilities further substantiate its growing stature in contemporary industrial landscapes.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025